In today’s society, the use of foams is more and more extensive. People use them to build thermal insulation, express package material, etc. However, people often discard them after they use them. The reason is that foam volume is too large and difficult to reuse. Thus, they become garbage and increase the burden on the environment. Actually, the waste EPS or EPE foam plastics can be recycled with the high-efficient EPS recycling machine and bring great economic benefits.

Introduction of EPS/EPE Foam

Foams are foamed plastics added with styrofoam. EPS is short for Expanded Polystyrene and EPE is Expandable Polyethylene. Due to the wide use of plastics, the market demand is huge and the consumption of supplies is large. However, the recycling rate of EPS/EPE foam plastics is not high. Against this background, how to make use of EPS and EPE foam has become a problem faced by many countries. Next, we will show you how to process EPS foam to create profits for you.

The Main EPS Recycling Machine in Eps Foam Processing Procedure

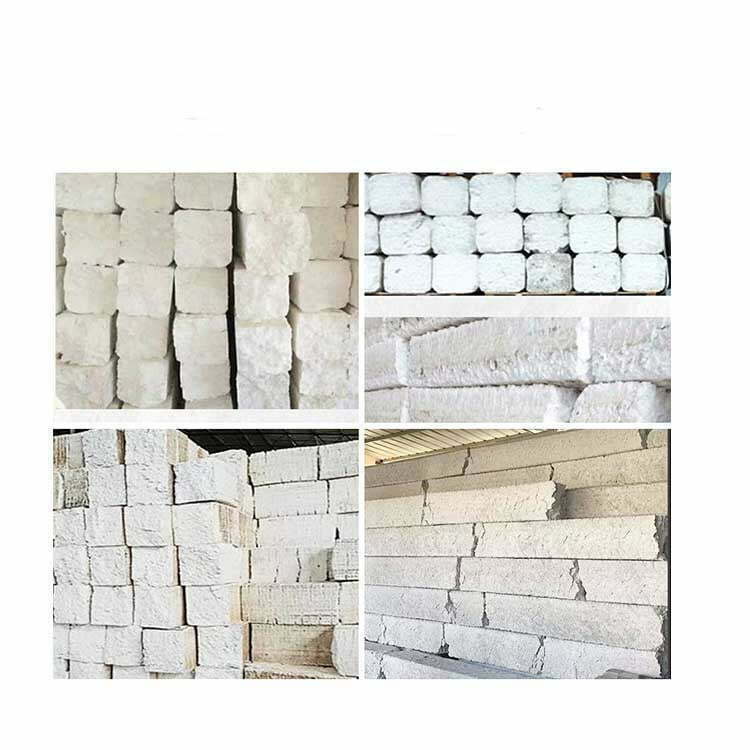

Waste plastic foam can be compressed into lumps by heating and melting, or dense blocks by compressing. In addition, the final products can be further processed to be plastic particles and consumer goods.

The common EPS recycling machines for dealing with EPS/EPE foam include foam crushing and melting integrated machine, foam cold compactor, and EPS pelletizer machine.

Eps/epe Foam Hot Melting Machine

The EPS hot melting machine has both crushing and melting functions, processing the raw foam materials to be lump shape.

EPS/EPE Foam Densifier

The EPS foam compactor can compress the EPS foam into dense blocks through screw compression.

EPS Pelletizing Machine

The EPS granulator can process the waste foam made of polystyrene into granules. The main machine is EPS foam granulator. It consists of two machines, which integrate crushing and melting functions. With the help of EPS granulator, you can easily get foam particles.

Advantages of Eps Recycling Machine

- The foam plastics can reduce space occupancy and transportation costs by crushing and compressing

- The value of plastic particles will increase greatly, and the market demand is great.

- The machines are affordable with low energy consumption.

- Under such a mode, the recycling efficiency of foam is greatly improved, the consumption of resources is reduced and environmental pollution is alleviated.

- Besides, the raw materials are easy to obtain, and the demand prospect of the market is promising.

Do you need these machines to make Eps particles? If interested in our EPS recycling machine, welcome to get in touch with us. Then we will try our best to help you.