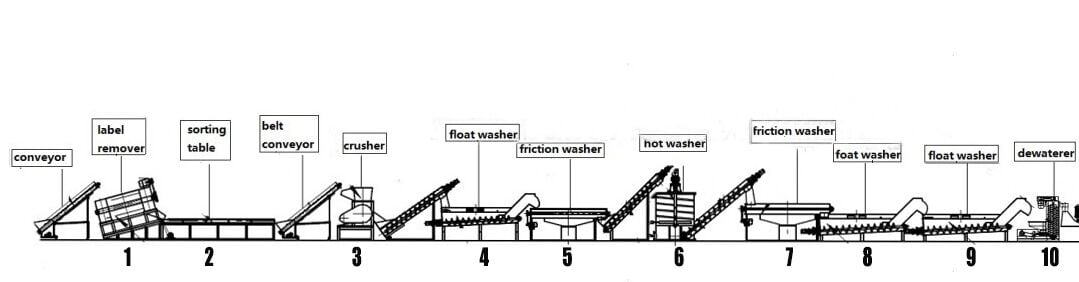

The PET bottle recycling line, also known as the PET bottle recycling machine, includes the process of plastic bottle de-marking, plastic bottle sorting, crushing, washing, high-temperature cleaning, friction cleaning, dehydration, and storage. The raw materials of the plastic bottle recycling line are water bottles and beverage bottles in daily life. Actually, we can use these final plastics flakes to produce plastic products, packing belts, the ingredient of tilts, etc. Our company designs and produces waste plastic bottle label remover, waste plastic bottle shredders, and other economic and environmental protection equipment. The machinery involved in this project can be customized according to customer needs.

Therefore, if you want to know what kind of machinery or our company, you can leave your phone number and needs on the site or at the end of the article. The following content will also involve information on how to choose the machine and the purpose of the equipment.

Plastic PET bottle manufacturers in China

Zhengzhou Shuliy Machinery Equipment Co., Ltd. was established in 2011 and is a well-known domestic machinery and equipment company. Our plant concentrates on manufacturing economic and environmental protection, agricultural and food equipment. Scientific considerations have been carried out on the selection of equipment parts, appearance design, and user production costs. In addition, we will provide a series of solutions for global customers. At present, 111 countries have successfully cooperated. We aim to help customers change the way of production and life by providing products and services, improving their production efficiency, and letting Chinese manufacturing take root in the world.

Machines in the PET bottle recycling line

Belt conveyor

This is one of the indispensable machines in the plastic bottle recycling line. Its overall frame is composed of steel, pulleys, and belts. During operation, it can transport raw materials or fragments to the next link. This is the first step to obtaining pure raw materials in the production line, which greatly improves work efficiency and discharge rate.

Lable removal machine

This machine is to remove the labels of the plastic bottles. There are many gears in the machine. When the bottle enters, the gear will rotate back and forth to scrape the label off. The outlet has a fan to blow the label out from one outlet and remove the labels from the other outlet, instead of manual de-labeling. Meet the needs of mass production. This design avoids the dangerous work of manual cleaning of discarded labels and material picking up, and the entire process is highly automatic.

Plastic crusher

Our plastic crusher is the most important step in the plastic bottle recycling line. And it is a necessary choice for the PET plastic bottle recycling industry. This step is to break the plastic bottle into pieces. There are 10 mechanical knives made of 9CrSi in this device that are convenient and quick to work. Compared with manual work, the crushing strength is greater, the products obtained are more refined, the processed materials are more diverse, and the amount is larger.

Washing tank

The plastic bottle washing tank is to carry out preliminary cleaning of the broken fragments. There is a screw pushing device inside, which pushes the material forward on the one hand, and flips the debris for cleaning on the other hand. This step is also the process of separating the PET bottle cap from the PET bottle fragments according to the different densities.

Hot water washing tank

This machine is an open-top structure with controllable internal high temperatures. Actually, plastic bottles will inevitably have various stains such as oil, mucus, and dyes. Appropriate high temperature coupled with appropriate detergent stirring can effectively remove product stains. The temperature reaches 80-90 Celsius Degrees. It is an important step to ensure product cleanliness.

Friction machine

The friction machine is composed of the main engine, motor, foot frame, water inlet, feeding inlet, discharge hole, and so on. The bottom of the body is a fine mesh filter, there is an external water inlet on the top. And materials are entered from the feeding inlet, the high-speed rotating screw allows the material to be fully rubbed with the running water. This step can achieve to clean the material completely.

Washing tank

The washing tank is to clean the PET fragments again. The screw pushing device inside pushes the material forward.

Plastic dehydration machine

A plastic dewatering machine is used for dewatering and drying the fragments. The wet fragments are transferred to the dehydrator by a screw conveyor for high-speed rotation to remove excess water and impurities and dried, so as to obtain a dry and clean finished product that is easy to store.

Storage bin

Storage bins can store finished products. The process mainly includes blowers, pipes, storage barrels, etc. The wind of the blowers is used to transport the dried products to the storage barrels for storage. This is convenient and fast and reduces the possible pollution in the construction process.

Features of PET bottle cleaning line

The whole set of PET bottle washing line has the advantages of high automation, low power consumption, high output, and high processing quality. So the final PET flakes are very clean and in small pieces, ready for making polyester staple fiber or plastic granules. The chemical fiber factory or plastic products manufacturers can directly draw and reprocess without further cleaning. At the same time, you can choose different combinations according to the types of raw materials and different requirements for bottle cleaning quality. So it can meet the needs of different users.

Video of PET bottle recycling equipment

How to choose the right plastic bottle recycling line?

When you choose the PET bottle recycling equipment, you must first clarify what the raw materials you want to process and the products you get, and then search for equipment on the Internet with a purpose. The equipment in the recycling of plastic bottles is basically the same. But due to the different cleanliness of waste plastic bottles, multiple cleanings are required during the production process. So it is necessary to purchase a variety of cleaning equipment. When purchasing, you can pay attention to the service life of the equipment, power consumption, cleaning methods, etc. If you buy from our company, we will take the initiative to ask your needs and give you reasonable suggestions, and consider it for you in an all-round way.

PET bottle recycling machine price

Presumably, everyone wants to know the price of waste plastic bottle recycling equipment. Due to the limitation of delivery time, transportation method, and other conditions, the price list of the PET bottle recycling line can be different. Moreover, the equipment is customizable. If you want the machine to have better parts and a more user-friendly design, we need to further discuss. We will give you more cost-effective products at a more favorable price.

What is plastic recycling?

Plastic recycling refers to the use of certain recycling processes to recycle waste plastics to achieve the purpose of turning waste into treasure. At present, waste plastics are mainly plastic films, plastic filaments and woven products, plastic packaging boxes and containers, daily plastic products, plastic bags, and agricultural mulch. The plastic bottle recycling line uses special pelletizing equipment to process waste polyethylene, polypropylene, and other plastics through crushing, cleaning, heating, plasticizing, extrusion molding processes to produce market-selling plastic pellets.

Effects of plastic bottle recycling

The value of plastic flakes

Most of the beverage bottles are made of PET, PE, PP plastics. There is an astonishing number of waste beverage packaging materials such as plastic bottles. Therefore, if they are effectively recycled and processed, they will generate huge recycling value and become a “resource for the place.”

How many times can PET t0 be recycled?

Can the plastic pellets obtain in the plastic bottle recycling line to produce plastic products again? The answer is of course. However, you must add virgin plastic during reprocessing. In this way, plastic recycling can be achieved. New scientific testing has shown that PET and HDPE which comprise 97 percent of all plastic bottles on the North American Bottle market can be recycled and reused for new containers at least ten times.

Contact us

The machinery in the PET bottle recycling line mainly includes a de-labeling machine, plastic bottle crusher, high-temperature cleaning machine, friction cleaning machine, etc. The company’s custom services are available to meet your needs. If you still have any questions, please contact us, or leave your contact information. Then we can solve the problem in detail for you.