PET bottle washing line is mainly a production line for cleaning and crushing PET plastic bottles. The PET bottle washing line mainly includes a washing tank, a hot water washing tank, and a frictional cleaning machine at least. Each machine is connected by a screw conveyor. If the budget is high or pursuing clearer finished products, you can increase the number of washing tanks, hot water washing tanks, frictional cleaning machines to two or three. What’s more, we can customize the washing equipment line according to your needs.

The Main Equipment of the Pet Bottle Washing Line

Label Separator

The plastic bottle label separator is the machine for removing labels from plastic bottles. Under the action of the rotation of the machine, the nail plate inside the plastic label remover can remove the label of the bottle body. After removing the label, the fan above the plastic bottle separator can blow the label out of the fuselage. Because the separation rate of this plastic label remover is between 98% – 99%. Compared with peers, Shuliy’s machine has great advantages in separation rate.

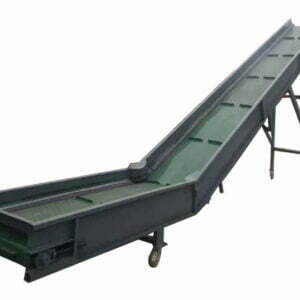

Belt Conveying Sorting Table Machine

The Belt conveying sorting table machine is a flat conveying table. It can separate the plastic bottles that have not been de labeled or plastic bottles of different colors. The purpose is to improve the purity of plastic flakes. As mentioned above, a small number of bottles have not been de labeled after passing through the plastic label separator. On the belt conveying sorting table, you can pick them out.

Plastic Crusher Machine

Pet Plastic crusher is one of the most important machines in the PET bottle washing line. The function of the plastic crusher is to crush the plastic bottle into a set plastic sheet size. Our cutting tool is high-quality steel, which can easily crush plastic bottles under the action of rotation. And the screen inside the machine is 12mm thick and the screen hole is 16mm. If you have the desired screen and mesh size, you can contact us and we can provide customized service. In addition, the size of the finished plastic flakes can customize according to your needs.

Washing Tank

The equipment is used for washing plastic flakes the first time after the crushing process. In addition, it also can separate plastic cap flakes made by PP or PE so as to improve the purity of PET flakes. And it’s suitable for further separation and rinsing after hot water washing and frictional machine to make bottle flakes cleaner. The washing tank runs stably with enough power, durable material, and is not easy to burn. It’s an important part of the PET bottle washing line.

Pet Bottle Frictional Cleaning Machine

The frictional washing machine applies to waste plastic cleaning as a supporting equipment of the PET bottle washing line. It consists of the main engine, motor, foot frame, water inlet, feeding inlet, discharge hole, and so on. There is an external water inlet on the top, a fine mesh filter on the bottom of the body. Materials are entered from the feeding inlet, fully rubbed with the running water by the high-speed rotating screw, removing impurities(soil, sand, leaves, paper, pulp), and then rinsing the dirty on the surface.

High-temperature Cleaning Machine

The hot water washing machine is widely applied to plastic cleaning thoroughly in hot water with detergent. It adopts an upper open structure with automatic temperature control, heating preservation, and stirring. And then the equipment is suitable for the PET bottle recycling line, heating rapidly, and cleaning conveniently.

Characteristics of Hot Water Washing Machine

- It measures and controls the temperature of the material by connecting the thermocouple with the temperature controller.

- There is a movable sleeve connecting the output shaft of the reducer and the paddle shaft, convenient to disassemble and clean.

- The surface of our shell adopts a mirror-polished matte finish.

- The internal surface is a mirror finish. The inner tank is no dead angle, cleaning material free from retention.

Parameters of High-temperature Washing Machine

- Volume: 5L, 10L

- Heating method: use coal or natural gas for heating

- Material heating temperature: no more than 90℃

- Stirring speed: 15 ~ 120r/min(constant speed)

Plastic Dewatering Machine

Plastic flakes dehydrator is the last main machine in the whole PET plastic bottle recycling line. It mainly dehydrates and dries materials. With the help of the plastic dewatering machine, the cleaned plastic flakes can directly enter the surge bin.

The Function of Plastic Flakes Made by the Plastic Bottle Washing Line

- Remanufacture PET plastic bottles. Recycled plastic flakes shall not be in direct contact with food. However, you can it in the middle layer of three-layer PET plastic bottles, and then made it into carbonated beverage bottles.

- PET plastic flakes can be made into fiber and used as sleeping bags, mattresses, pillow core, felt, etc.

- In addition to making pet plastic bottles, you can use it to make car wheel covers, etc