Plastic film recycling machine includes belt conveyor, plastic crushing and cleaning machine, rinsing tank, vertical type dewatering machine, inclined belt conveyor, automatic feeding machine, plastic pellet extruder, cooling tank, pellet cutting machine, storage bin, bagging machine, etc. Plastic film will become granular plastic through the whole process. The plastic film recycling machine applies to a lot of plastic products, such as plastic bags, woven bags, or other plastic films made by PE or PP. In addition, we can customize these plastic recycling machines according to your needs.

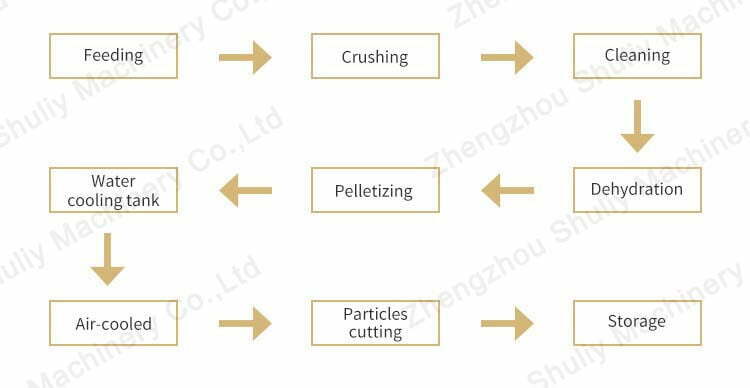

The production process of plastic film recycling machine

The process of plastic film recycling and reprocessing has some slight differences because of different materials. But the main steps are the same. The raw materials will be transported into a plastic film shredder and washing machine by belt conveyor to be crushed and washed. The crushed film flakes are cleaned throughout in a sink. Then vertical type dewatering machine puts material out and dries it. Dried film scraps go along with the climbing conveyor into the automatic feeding machine. Because soft films are very light, it’s not convenient to send them into a plastic pellet-making machine directly. So it needs an automatic feeding machine to help. Then, the plastic film granulator extrudes long strips. Next, cooling soft strips in the cooling tank, cutting them into granules by the cutter. Then collecting these materials in a storage bin. And finally packaging these granules into bags.

Plastic recycling machine working video

Application of plastic film recycling machine

Plastic film recycling machine widely applies to a variety of films, such as PE, PP, PC, PET, ABS, HAPE, PVC, EPS, etc. In addition, we can see plastic film products everywhere in our daily life, such as food packaging bags, plastic wraps, beverage packaging films, woven bags, tablecloths, bubble wraps, and so on. They all can be dealt with by the plastic recycling machine to become granules for recycling use. The plastic film recycling line is different because of the diverse properties of different materials. You can choose suitable machines to compose the production line based on your needs or get in touch with us to get helpful suggestions. Besides, OEM service is available according to your requirements.

Plastic recycling equipment involved in plastic recycling line

- Belt conveyor is the device to convey plastic film to a crushing machine. With the help of the belt conveyor, the material can be easily sent to the plastic crusher.

material conveyor - Plastic film shredder and cleaning machine are used for crushing and washing material. The plastic crushing and cleaning machine is mainly used for crushing and cleaning materials in the plastic film recycling line. The rotary cutter inside the crusher can cut and crush the materials, and clean materials at the same time. After crushing, the materials enter the plastic washing machine below for secondary cleaning. In addition, our machine is made of high-quality steel and is durable.

plastic shredder - Rinsing tank rewash broken materials throughout and is equipped with tooth plates to force plastic chips to move forward the other side.

rinsing tank - Vertical dryer for plastic film chips includes the devices of strong swirling cleaning, automatic conveying, high-speed centrifugal dehydration, etc. Therefore, plastic dewatering machine can dehydrate and dry materials in a short time

vertical dehydrator - Automatic feeding machine helps soft materials like plastic film enter into a plastic pelletizer machine.

automatic feeding machine - Plastic granulator machine is the main machine of the whole plastic recycling line. It is a device to melts and extrudes polyethylene and polypropylene into long strips. It can deal with plastic film, lining bags, old woven bags, packaging bags, tying rope, etc.

plastic granulator - Cooling tank is mainly used for cooling soft strips, making them shaped and hard.

cooling tank - Pellet cutting machine will cut cooled long strips into small granules by hard alloy hob, convenient to store and secondary use.

pellet cutting machine - There is a pump underneath the storage bin that can continuously suck plastic particles into the inside of the machine. 储藏仓的下方有一个泵

storage bin

Features & benefits of these plastic film recycling machines

- Low energy consumption, high output, pretty appearance, practical and reliability;

- Mass production for plastic film granules, high efficiency and save labor.

- Various kinds of related machines are optional. A set of plastic film recycling machines can be chosen and purchased through a one-stop service.

- We can customize many specifications according to your needs. And we have successful cases from 200kg/h to 3000kg/h.

- Different cleaning plans, cleaning processes, recycling plans, and site plans are provided for you according to your actual situation.

- Specialized designs and suggestions are available according to your needs.

- It’s significant meaning for environmental protection.

Working video of the plastic recycling line

https://youtu.be/9dIUNzOCbLw

A field trip is a good idea when purchasing the plastic film recycling machine

We suggest that you come to our company and factory if you want to invest in plastic film recycling equipment. We can talk face to face and arrange you to our plant to see machines closely. A field trip is important and it can help you learn more about the pieces of equipment. Our company has been engaged in plastic film recycling equipment for over 10 years. And we have received orders from all over the world. A field visit is an extremely intuitive inspection. You can think over your options and our suggestions comprehensively, such as the size of the rinsing tank, the kind of plastic film pelletizing machine, which machines purchase, etc.

Why do we need plastic film recycling machines?

Plastic products have been an indispensable part of life in recent years. Plastic production is made from petroleum. Burning plastic will produce poisonous gas which is terrible for humans and the natural environment. Therefore, dealing plastic products in a proper way is significant. Plastic recycling machine plant makes plastic recycling use possible. The plastic recycling line with plastic granulators can make plastic pellets for recycling.