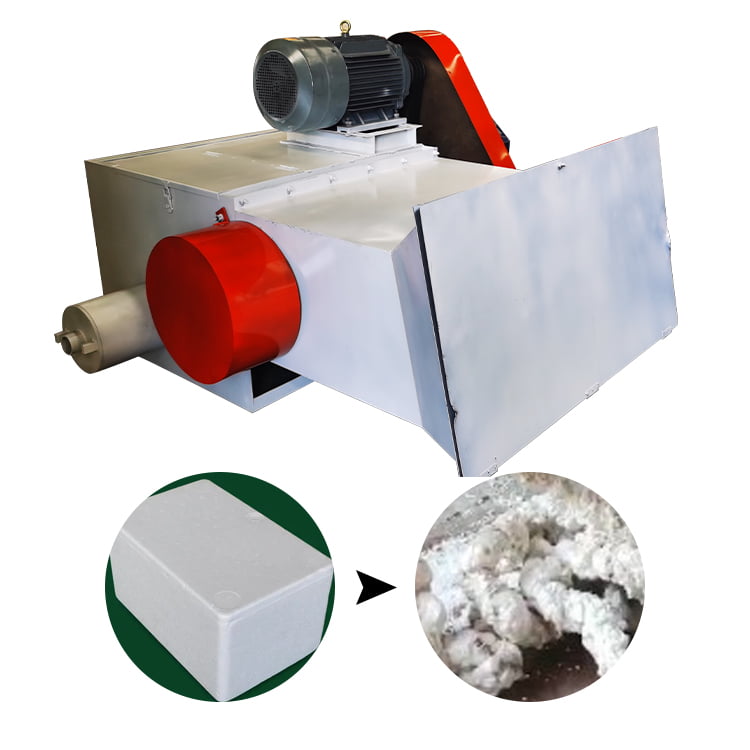

The EPS Foam Melting Machine is a piece of professional mechanical equipment for recycling waste EPS/EPE foam by forming it into lumps. It is the automatic production of the whole equipment of foam plastic melting machine, with automatic control of temperature and automatic discharge. Thus, it saves a lot of manpower and material resources for users. In addition to EPS foam melting machines, we also provide foam crusher machines, foam cold compactors, foam granular machines, etc.

To start up the EPS foam melting machine, it is necessary for users to pay attention to several key points for proper and safe operation.

Foam plastic melting machine start-up steps

- First, the EPS hot melting machine should be fixed on the horizontal floor to avoid vibration and displacement during operation, and foam overflow and leakage.

- Before operation, the workers shall check the safety of the electric lines and the state of the equipment. They shall observe whether there are foreign matters in the feed inlet and barrel, whether all equipment has been installed in place.

- Then, start the machine for idling after checking, and observe whether the operation conditions of all parts are normal, etc.

- Start production after all inspections meet the requirements. The feeding worker shall keep feeding at a constant speed. The feeding amount can be adjusted appropriately according to the discharging speed. Remember that continuous feeding of large volume of foam can not be carried out so as to avoid the uneven melting of the foam in the barrel and affect the quality of the extruded hot frit.

- When the EPS foam melting machine is in stable production, the operator only needs to maintain the feed and check the working parameters of the equipment in time to see if there is any abnormal condition.

Notice

- Pay attention to power safety during operation.

- An air switch shall be set at the line connection.

- At least one air switch is also set on the main line.