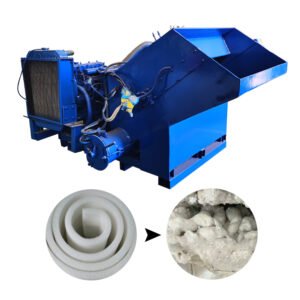

EPS foam densifier is also known as the EPS briquetting machine, used for compressing foam plastics, such as EPS or EPE foam plastics. The working principle is to compress the EPS foam into dense blocks by means of a screw compression mechanism. According to the characteristics of raw materials, the compression ratio can be up to 40 times, so as to reduce the volume of foam. The foam blocks are convenient for long-distance transportation and storage, which save transportation cost and storage space. In addition to the EPS foam cold compactor, we also provide foam hot melting machines to reduce the volume of waste EPS or EPE foam plastics.

Highlights EPS foam densifier

- After compressing the EPS foam volume 30-40 times smaller than before, the foam density is large, and the foam blocks are easily cut off, stored, and recycled. Save storage space and transportation and storage costs

- It is equipped with a pre-crushing mechanism to ensure working efficiency and maintain low energy consumption. Different sizes of feeding ports can be selected for cold pressing treatment.

- Large models can operate synchronously with the conveyor belt to improve production efficiency.

How does the EPS compactor work?

EPS foam cold compactor compresses foam plastics according to the principle of screw rotation and cold compress. In operation, the operator just needs to throw the waste foam into the hopper, and the EPS foam densifier has a shredding mechanism to crush the foam block. Then the screw mechanism compresses the small EPS foam into a cubic compression block. There is a pressure regulating device at the front end of the compression section to adjust the compression ratio. After the material is processed by the screw mechanism, the square foam compressing block is formed. Great reduction of the foam volume is conducive to foam recycling.

Two types of EPS foam cold compactor

We offer two kinds of EPS foam densifiers to meet the different needs of customers.

1. Vertical type

The feeding port of a vertical foam densifier is on the upper part of the machine, which needs to lift the raw materials to the height.

Specification (vertical type machine)

| Mode | SL-300 | SL-400 |

| Machine size | 3000*1400*1400mm | 4600*1600*1600mm |

| Inlet size | 1100*800mm | 1200*1000mm |

| Motor power | 11kw | 22kw |

| Output | 150kg/h | 250kg/h |

2. Horizontal type

The height of the feeding port of a horizontal foam compactor is flush with the ground, which is more convenient for feeding.

Specification (horizontal type)

| Mode of horizontal type | SL-300 | SL-400 |

| Machine size | 3000*1700*900mm | 4600*2800*1200mm |

| Inlet size | 830*760mm | 870*860mm |

| Motor power | 15kw | 22kw |

| Output | 150kg/h | 300kg/h |