The use of plastic is increasing more and more nowadays, just like water and coco-cola are used in plastic bottles. These two different types of drinks are used in large quantities, not only in certain countries but in every country. Most people drink the material in plastic bottles and throw it in the trash. Because they think empty plastic bottles are waste and useless.

Is It Necessary to Recycle Plastic Bottles?

Recycling every type of plastic is necessary because empty plastic has no use in the world, and pollutes the environment in one way or another. If empty plastic bottles are not recycled, and if they are burned, then carbon can spread out in the air, polluting the environment and being dangerous to people living near areas where such activities take place. Recycling plastic can both protect the environment and promote the consumption and manufacture of new plastics.

It is also important, if plastic bottles are not recycled, recycling plastic will not be used in the manufacture of the same type of goods again. Once the plastic is recycled and melted, it can be used in the manufacture of different products, such as plastic bottles. And then can make plastic chairs by recycling plastics. Recycling is very important because it will affect the cleanliness of the city. In particular, the recycling of pet plastic bottles is even more important, as pet bottles are consumed and thrown into the trash. And in third-world countries, plastic bottles can be found on the ground.

The Challenge of Plastic Recycling

One of the challenges with plastic recycling is that compared to glass, plastic takes a long time to recycle and therefore requires time and heavy machinery. And the fact that plastic is more useful after recycling than glass or anything else that can make the same thing. The structure of plastic bottles has a very strong structure. Because it is made from plastic polymers, so heat to melt the plastic, it needs to heat the bottle in the machine more than a simple process, such as glass sample consideration again.

Because there are many kinds of plastic, so in before entering the recycling plastic, it should be a category. Plastic is used in the manufacture of plastic polymer level category. The recycling process is monomer recovery, then pyrolysis, the last step is to hot compress.

Advanced Thermoforming Plastic Recycling Process

Thermoforming is an advanced plastic recycling process to recycle plastic waste material. It is almost the same basic process as vacuum forming, but hot forming is typically used to require more complex and more thermal forming machines of medium-sized plastic industry.

Thermal forming is a great plastic recycling process in particular on the mold of plastic molding temperature heating process. And then is to make available products finishing process. Thinner plastics or certain materials are heated in a molding furnace until the material can be stretched; And on the basis of mold forming, until it cooled and pop-up.

The thermoforming plastic recycling process usually needs a large and complicated plastic hot-forming machine, then according to the shaping mold, for the mass production. Hot molding process for plastic materials from thin or thick plastic material production.

Thin plastic is typically used for disposable materials production, such as plastic water bottles, cups, blisters, lids, trays, and many other disposable materials. This process is a thin plastic on the roller feeder, then on other machine parts. In this process, the plastic is punctured and transported into the oven. The plastic sheet will be heated to molding temperature, and then in the process of forming, plastic and mold. Then he will continue the process of suspension process. When the molding plastic into the closed pressure box, plastic vacuum forming to remove residual air, with pressurized air will plastic molding, plastic molding for mold shape in detail. Another process lasted until the manufacturer produce high-quality disposable plastic material. The waste from this process is recycled for grinding of another product or modified waste to make their own facilities.

In fact, the manufacturer will turn the waste back into raw materials. They use thick plastics to make permanent structural components. Thick plastic materials are molded in much the same way as in materials except that they are molded using a vacuum process.

Thick plastic materials are commonly used for end-use tools. For example, airplane doors, refrigerators, weapons, power tools, and more heavy-duty equipment.

What Are the Hazards of Plastic Products?

If we can’t recycle this material into something beneficial, plastic materials are a dangerous waste product. And thermal molding is one of the best tools for reducing plastic waste. Because producing a lot of products that can recycle a lot of plastic waste around your environment.

Many countries have a lot of plastic garbage. Because still many markets and households use plastic as their bags, and still don’t know how to recycle these materials. So, thank god invented a simple plastic recycling machine and thermal forming technology, so much plastic is, again and again, to be recycled. However, we still need to reduce plastic use to prevent climate change.

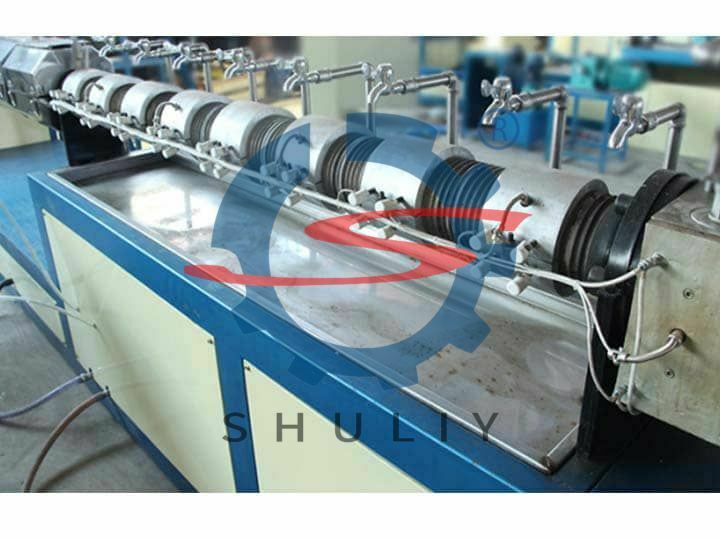

Contact Us

Shuliy is one of the leading plastic recycling machine manufacturers. We provide excellent plastic film recycling plants and pet plastic bottle recycling plants. Since we were founded, we aim to be a great company that can contribute to a better world. Get in touch with us for suggestions from experts.