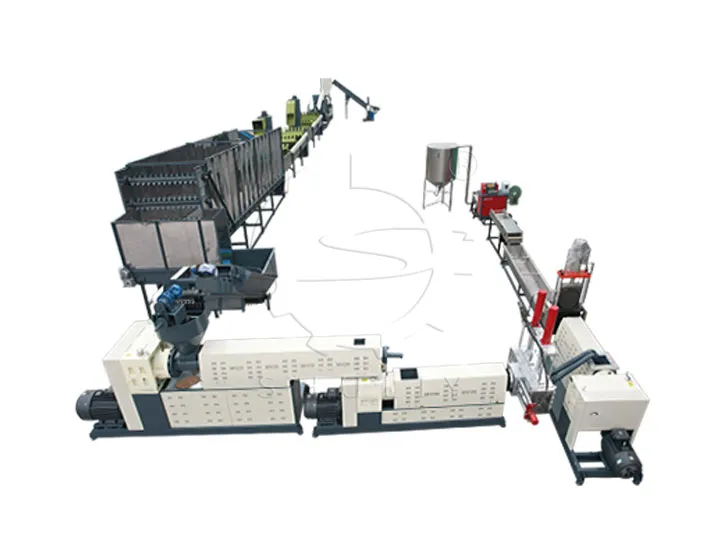

How can recycled plastic pellets be effectively manufactured with less effort? To achieve this, selecting a high-quality extruder plastic pelletizing line is essential. Hard plastic recycling, such as PVC pelletizing line involves several steps, including crushing, washing, pelletizing, drying, etc., which will be explained in this post.

Key Features of Shuliy PP/PE/HDPE/PVC Pelletizing Line

- Wide Applications: The rigid plastic granulation line can handle various hard plastic materials, including PP, PE, HDPE, PVC, etc.

- High Production Efficiency: The production capacity is approximately 100-500kg/h and can be customized to efficiently meet the production needs of small, medium, and large recycling plants of all sizes.

- Superior performance: Made of high-quality stainless steel and equipped with a strong motor, excellent filtration system, etc., our plastic granulating machine can produce continuously and stably without frequent downtime to replace the filter.

- High quality of finished products: By adopting advanced screw melting and granulation technology, the finished plastic granules have high purity, no contamination, uniform size, and stable performance, and can be directly used in blow molding, injection molding, and other new plastic manufacturing processes.

- Easy to use: high degree of automation and equipped with intelligent cabinets that can safely and efficiently control the progress of plastic recycling in real time.

- Easy to maintain: Modular design makes our rigid plastic recycling equipment easy to clean and maintain. We also offer technical support and a free one-year warranty.

Raw Materials And End Products Of the Rigid Plastic Recycling Line

Raw Materials:

Our hard plastic recycling lines are commonly used to recycle waste rigid plastics from various sources, commonly:

- Construction industry: PVC pipes, HDPE waterproof sheeting, etc.

- Packaging industry: PP plastic pallets, HDPE blue drums, etc.

- Automotive industry: ABS bumpers, PP dashboard, etc.

- Furniture industry: ABS plastic tables and chairs, PP/PE decorations, etc.

- Electronic industry: electronic insulation shell, etc.

- Others: PP/PE toys, industrial trimmings, etc.

End Products:

After a series of processing such as shredding, cleaning, and pelletizing, waste plastics can be converted into uniform recycled pellets. The size of these finished pellets can be set according to demand, with high quality, and can be directly used in the manufacture of plastic products in the above industries.

How To Recycle Hard Plastic?

1. Shredding

Using a plastic shredder to break rigid plastics into small and uniform flakes facilitates subsequent processing and improves the efficiency of rigid plastic recycling. The hard plastic crusher can realize 600-1200kg/h plastic crushing capacity by the combined force of rotating movable knives and fixed knives. The design of a large feed inlet makes it run without jamming and clogging, which lays a solid foundation for smooth and stable PVC pelletizing extrusion.

- Capacity: 600-1200kg/h

- Power: 30-55KW

- Blades Materials: 60Si2Mn

- Raw Materials: All shapes of hard plastics, including PP, PE, PVC, HDPE, ABS, etc.

- Final Products: Uniform smaller plastic flakes

2. Washing

Next, use the plastic washing machine to remove the dirt, stains, and other impurities from the crushed HDPE/PVC/PP/PE/ABS scraps, to improve the purity and quality of the recycled plastic pellets. Shuliy plastic washing tank is made of high-quality stainless steel with an extended and deepened large-capacity design, which can meet the cleaning needs of most factories, and it’s durable and corrosion resistant. In addition, we can also customize it according to your specific needs.

- Length: 10-30m

- Materials: High-quality stainless steel

- Raw Materials: Crushed plastic flakes with impurities

- End Products: High-purity plastic scraps

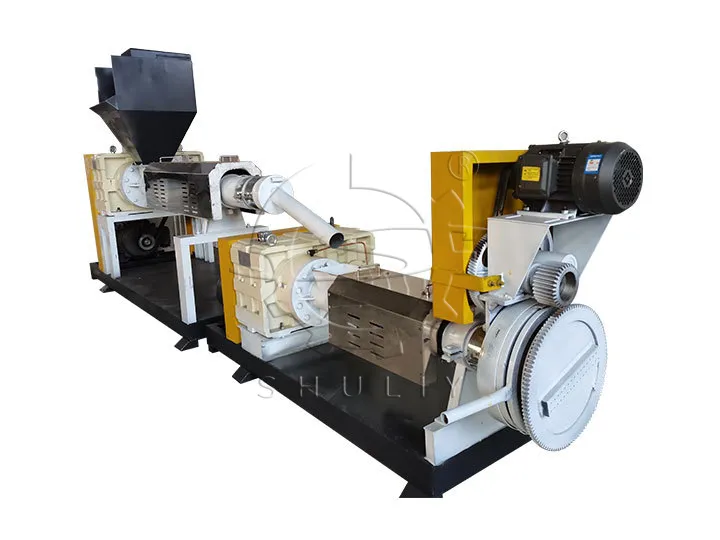

3. Granulation

Pelletizing is a key step in converting plastic scraps into pellets. Plastic chips are heated and extruded into long strips by a plastic extruder, then cooled and formed by a cooling tank. Finally, the pellets are cut with a plastic Dana cutting machine.

It is important to maintain stable and continuous production in the plastic pelletizing process, which is related to the performance and quality of recycled pellets. Shuliy plastic pelletizing system can effectively remove incompletely melted impurities and improve the quality of finished products while ensuring stable pelletizing. Real-time temperature control through smart cabinets, etc. can also contribute to safe and accurate production.

- Capacity: 180-380kg/h

- Power: 30-75KW

- Part: Plastic extruder, cooling tank, plastic Dana cutting machine

- Raw Materials: Cleaned plastic chips

- Final Products: Uniformed recycled granules with stable performance and no pollution.

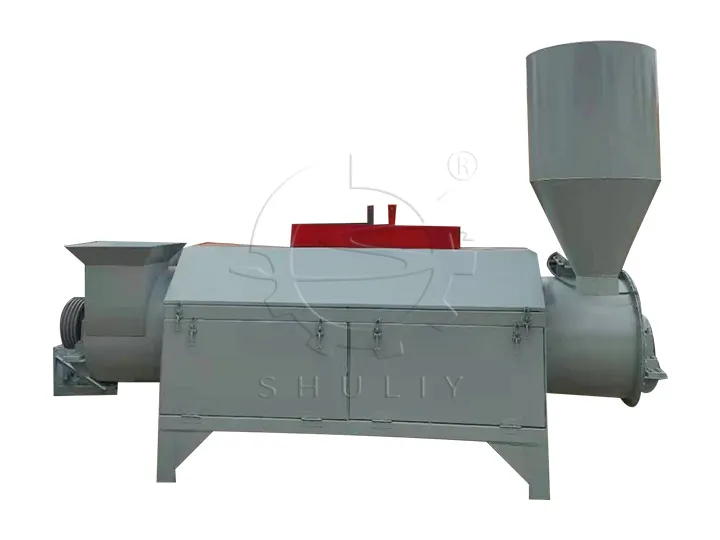

4. Drying

Plastic dryer machines are used to uniformly dehydrate and dry recycled plastic pellets for subsequent storage and transportation.

- Power: 7.5-15KW

- Propeller Blade Rotational Speed: 900-1500r/min

- End Products: Dry Plastic Recycled Granules

Shipping About Our PVC Pelletizing Line

- After placing an order, the custom machine will take about 15-20 days of work.

- We will send you regular progress reports, including pictures and videos of the PVC pelletizing extrusion line.

- International shipping of the machine

- Provide technical support, on-site installation, one-year warranty, and other services.

Proven Results Of Our PE Plastic Flakes Pelletizing Line

Our rigid plastic pelletizing line has been successfully sold in countries such as Oman, Nigeria, and South Africa. This equipment has helped our customers achieve efficient pelletizing, increase profitability, and support the development of the circular economy. If you are interested in rigid plastic recycling, please feel free to contact us. We are committed to advancing the plastic recycling business worldwide!

Summary

The PVC pelletizing line is a great solution for recycling waste PP, PE, HDPE, PVC, ABS, etc., which has been successfully implemented in various industries to transform plastic waste into high-quality pellets for reuse. If you’re seeking for pelletizing solution, your opportunity is here—reach out to us today to find out more!