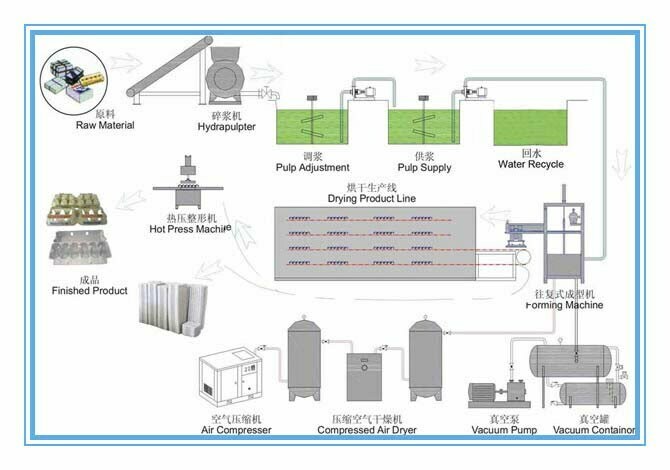

Egg tray reshaping & packing progress is the final stage of the entire egg tray making progress. It contains two steps: hot pressing and packaging. Thus hot pressing machine and packaging machine are required. The hot press is to reduces the volume of the egg tray and saves space. The packaging machine is to pack the finished products. But you can choose manual packaging or automatic packaging according to the actual needs. Generally speaking, during the progress of making egg trays, only egg boxes should be reshaped. This step always is going on after drying. So, the entire process of making egg trays includes pulping, forming, drying, hot pressing, and packaging. Please contact us for more messages!

Egg Tray Reshaping Progress

In this process, the hot press is an indispensable machine. The hot press is specially used for environmentally friendly products such as egg boxes to make the surface smoother and more beautiful. Also, after reshaped egg carts, it saves space and more pieces can be stored. The structure of the hot press includes the following parts: control panel, cylinder, guide rod, frame, adjustment plate, upper template, lower template, triplet, and pressure regulating valve. And it is controlled by air control. But it should be noted that the compressed air of the working medium of the pneumatic control must be purified and dried, so as to ensure the service life of the air control.

Packing Progress

This progress is the end step. Packing machine is used for packing egg tray, easy delivery. The entire progress of making egg tray is orderly pulping, forming, drying, reshaping, and packing. Pulping is to make waste paper or magazine, etc. into pulp. Forming is to make pulp into mould dies. Drying is to dry the mould through natural drying, brick drying, or metal drying. Reshaping and packing are to reshape the mould and easy to deliver. For making an egg cart, every step is absolutely necessary. Everything should be matched. So, if you have any doubts, please contact us as soon as possible!

Instructions for Hot Pressing Machine

Check items before starting up:

- Check whether the machine mould is installed firmly.

- Check whether the movable parts of the machine are well lubricated, and whether the screws of each part are loose.

- Check whether the working air pressure and working temperature meet the requirements of the production process (air pressure is 0.5±0.05MPa, working temperature is 165±15℃), and turn on the temperature control switch on the panel.

- Manually operate the machine to check whether the operation control of the machine is normal.

Operation method:

- The inspection work is completed and confirmed before starting up, and the production operation can be carried out.

- Switch the “manual/automatic” rotary switch on the operation panel to the automatic position.

- Take the semi-finished product that matches the mold on the equipment and put it flat on the mold, and press the two start switches with both hands at the same time.

- After the upper and lower workbenches of the equipment are closed, release the start button to prepare the next product and wait for the upper and lower molds to separate.

- After the upper and lower molds are separated, take out the shaped product and check whether the product meets the quality standard.

- Check and finish stacking the finished product to continue the shaping work of the next product.

Matters needing attention:

- 1. Operators must wear gloves and sleeves when working to avoid burns.

- 2. It is strictly forbidden for one person to start the machine and multiple people to pick and place the product to avoid crushing.

- 3. Pay close attention to the operation of the equipment during work. If there is any abnormality, press the emergency stop switch and turn off the power immediately, and report to the supervisor on duty and related technical personnel in time.

Maintenance

- During equipment use, always check whether the gas supply system is normal, whether the power supply line is normal, whether there is any damage and line heating.

- When abnormal impact or noise occurs during the equipment operation, it should be shut down immediately for inspection to find out the cause and eliminate it.

- Pneumatic parts must be lubricated, and No. 20 engine oil must be added to the oil cup on the triple piece regularly.

- For long-term shutdown, lower the upper mold to the lowest position, pad the upper and lower molds with wood, and close the air source to the equipment. Regularly refuel and check the moving parts of the equipment to ensure the normal operation of the equipment when in use.

How About Our Service?

All products purchased in our company are guaranteed to keep in good repair for one year. If quality problems happen in guarantee period, our company will maintain for free.

- Before sending the machine, we will test and do commissioning, so you can use it directly when you get it.

- Operation video & instruction will be sent to clients, to help them use the machines better.

- Any problems occur while using, professional advice will be offered.

- All kinds of frequently used parts are supplied all year round.

Additionally, our company provides technical support and fittings for life. After-sales service isn’t restricted by time and we will solve your problems in time. If you are caught in some problems when using our products, welcome to contact us at any time.

Conclusion

Machines used in the reshaping and packing progress are of reasonable structure, stable performance, and exquisite appearance. The price differs according to the whole machine collocation. As a reliable and highly reputed company, we’re located in the convenient transportation hub of China. Hence, usually, the cost-effective delivery method is applied. Namely, sea transportation. However, during sea delivery, the package is very important. Thus, machines from our company, Zhengzhou Shuliy Corporation, will be wrapped in plastic film before packaging, in order to avoid moisture during the shipment. Besides, they’re put in a strong iron sheet case/wooden case which is free of fumigation, lined with metal wire if necessary. We also support customization services. Looking forward to your inquiries! We’ll reply very soon!