Struggling with tangled textile waste and inconsistent recycled fiber quality? Shuliy’s high-performance Fiber Opening Machine is your solution. Engineered for industrial use, our machine transforms messy scraps—like cotton cloth, yarn waste, and non-woven fabrics—into valuable, fluffy fiber with an exceptional opening rate of 93-97%. Stop losing money on inefficient processing and start maximizing the value of every fiber.

Applicable Materials for Fiber Opener Machine Processing

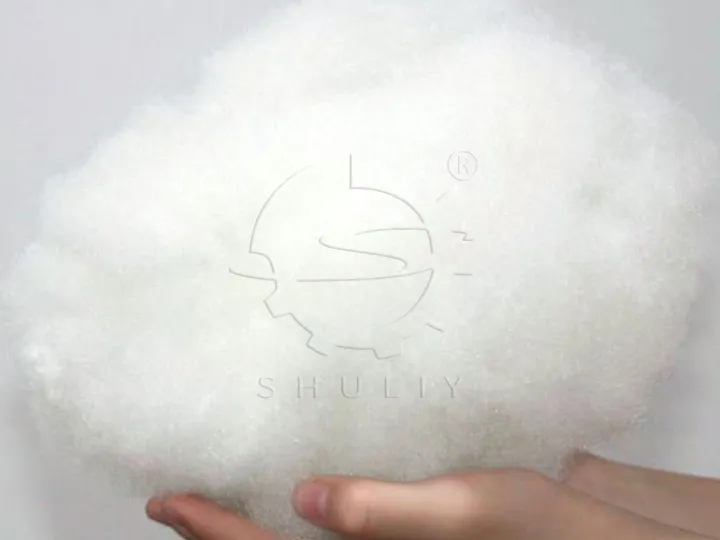

Our fiber opener is the ideal choice for a wide array of businesses looking to add value to their materials. After opening, the fibers feature high fluffiness, even distribution, low impurity content, and intact fiber structure.

Commonly Processed Materials:

PP Cotton, Doll Cotton, Hollow Cotton, Polyester Staple Fiber (PSF), Natural Cotton, Wool, Non-woven Fabric Scraps, Waste Cloth, Yarn Scraps, and more.

Ideal for These Industries:

- Home Textiles: For filling pillows, cushions, duvets, and bedding.

- Furniture Manufacturing: Creating high-quality fillings for sofas and chairs.

- Toy Manufacturing: Producing safe and soft stuffing for stuffed animals and dolls.

- Pet Products: Making comfortable and durable fillings for pet beds.

- Apparel & Textile Mills: Recycling garment offcuts and yarn waste into reusable fiber.

Key Features of Our Cotton Opener Machine

Our fiber opening machines are not just equipment; they are a complete solution designed to boost your productivity and profitability.

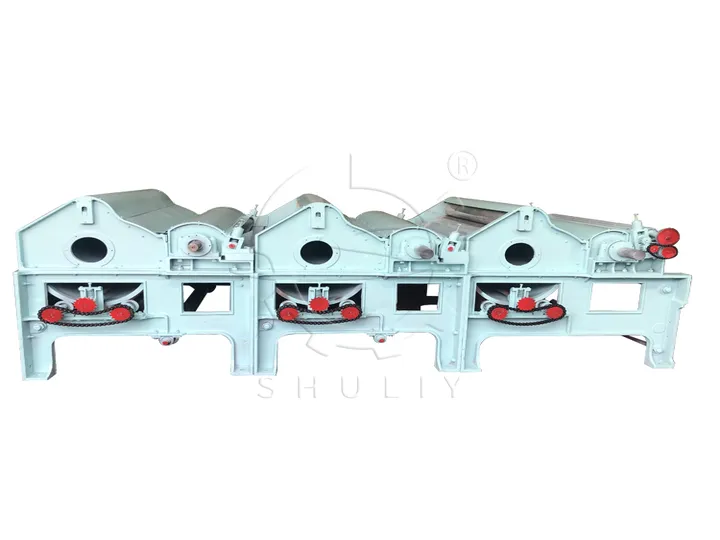

- Scalable Production to Match Your Growth: We offer a full range of models, from 1-roller units for startups to powerful 4-roller systems for large-scale industrial operations.

- Superior Final Product Quality: Our precision-engineered carding process gently opens fibers without damaging their structure. The result is a consistently soft, uniform, and impurity-free output, perfect for high-value applications and commanding a better market price.

- Built for Industrial Demands: Constructed with a heavy-duty steel frame (weighing 800 kg to 3200 kg) and featuring dynamically balanced main rollers, the fiber opener machines are built for continuous, stable operation. This means less vibration, longer service life, and minimal downtime.

- Versatility in Application: One machine handles a vast range of materials. Effortlessly process everything from raw cotton and wool to polyester fiber and textile offcuts, making it a versatile asset for any production line.

- Reduced Operational Costs: High efficiency means less energy consumption per kilogram of fiber produced. The high-quality output also reduces material waste and eliminates the need for costly reprocessing, directly improving your bottom line.

Parameters of the Polyester Fiber Opening Machine

Our fiber opening machines are engineered to transform raw fibers and textile waste into high-quality, reusable material. Choose the perfect solution for your production line. If you have any questions, please feel free to contact us!

| Feature | Entry Model | Standard Model | Pro Model | Elite Model |

| Model ID | FO-1000-1R | FO-1000-2R | FO-1000-3R | FO-1000-4R |

| Best For | Start-ups, basic waste tearing | Small to medium factories | High-quality fiber processing | Demanding industrial applications |

| Opening Stages | Single Stage | Double Stage | Triple Stage | Quad Stage |

| Fiber Output Quality | Good | Better | Excellent | Superior/ High-purity |

| Hourly Production | up to 250 kg | up to 400 kg | up to 550 kg | Up to 700 kg |

| Power Requirement | 11 kW | 29 kW | 34 kW | 40 kW |

How Does the Textile Opening Machine Work?

Our machine transforms raw or waste textiles into premium, reusable fiber through a sophisticated multi-stage opening process.

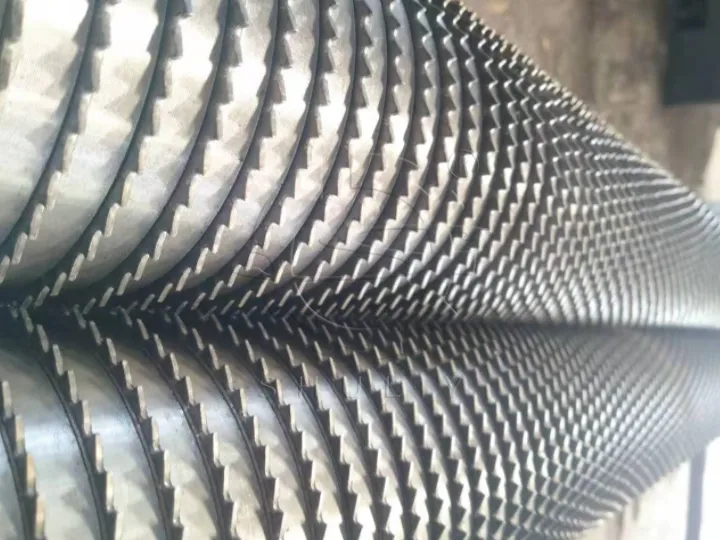

- Initial Feed & Primary Opening: Material is fed into the system and meets the main high-speed roller. This powerful, dynamically balanced drum does the heavy lifting, breaking down compressed bales and large clumps.

- Progressive Combing & Refinement: The fiber then travels across a series of smaller, specialized rollers. Each roller is equipped with unique wire teeth that progressively comb and detangle the material, ensuring a gentle yet thorough separation.

- Gentle & Damage-Free Output: Unlike aggressive tearing methods, our system is engineered to preserve fiber length and strength. The result is a soft, clean, and consistently high-quality fiber, maximizing the value of your material.

This entire process is built on a foundation of stability and durability, ensuring continuous operation with minimal downtime and low maintenance needs.

Build Your Complete Fiber Processing Line

When you choose Shuliy, you get more than just a machine. You get a reliable partner dedicated to building your success.

- Expert Consultation: Our team will help you choose the perfect fiber opening machine for your materials and production goals.

- Need to Pre-Process Large Materials? For oversized textile waste, long ropes, or tangled yarn, a fiber cutting machine is the essential first step. It efficiently cuts materials down to a uniform size, ensuring optimal performance and preventing clogs in your fiber opening machine.

- Global Shipping & Support: We ship worldwide and provide comprehensive technical support and a 12-month warranty for all our equipment.

Ready to Upgrade Your Fiber Processing Line?

Stop letting valuable material go to waste. Contact us today to discuss your project—from a single machine to a fully integrated processing line—and get a personalized, no-obligation quote.