Transform low-value aluminum scrap into high-purity (up to 99%) renewable resources with Shuliy’s fully automated aluminium recycling plant! This robust system processes everything from UBC and window frames to car shells, offering capacities ranging from 1 to 10 t/h to produce clean, furnace-ready aluminum flakes. Boost your profitability and step into the circular economy today.

What Raw Materials Can Our Aluminium Recycling Plant Process?

Our versatile aluminium recycling plant is engineered to handle a vast range of post-consumer and industrial aluminum scrap. The goal is to separate valuable aluminum from contaminants such as iron, plastic, and paint.

- Light Scrap: Used Beverage Cans (UBC), aluminum shavings, broken window profiles, and tabor scrap.

- Automotive Scrap: Car shells (after removing the engine), aluminum engine blocks, radiators, and wheels.

- E-Scrap: Aluminum casings from electronics and appliances.

- Mixed Metal Scrap: Zorba, where aluminum is the primary non-ferrous metal.

The final products are exceptionally clean aluminum fragments and separated ferrous metals (iron and steel), ready for immediate sale to foundries and steel mills.

Key Features of Our Scrap Metal Recycling Line

Investing in a complete processing line is a major decision. Our system is not just a collection of machines; it’s an integrated solution designed for maximum efficiency and return on investment.

- High Purity & Profit: Achieve up to 99% separation purity thanks to our advanced eddy current separator, significantly increasing the market value of your final product.

- Fully Automated Operation: From feeding to final separation, the entire aluminium recycling plant requires minimal manual intervention, reducing labor costs and improving safety.

- Customizable Capacity: We design lines from 1 t/h for smaller yards to over 10 t/h for large-scale industrial operations.

- Robust & Durable: Key components like our metal crusher and shredder are built with high-manganese steel and undergo rigorous quality control for long-lasting performance.

- Eco-Friendly Processing: The integrated dust removal system effectively controls airborne particles during crushing, ensuring compliance with environmental regulations.

How Does the Aluminium Scrap Recycling Plant Work?

The process is a symphony of shredding, crushing, and precise sorting. Each stage is designed to efficiently prepare the material for the next, culminating in the recovery of pure aluminum. Here’s how our aluminium recycling plant works:

Step 1: Initial Size Reduction (Double-Shaft Shredder)

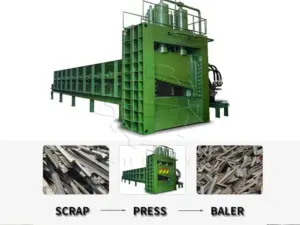

Large and bulky materials, like baled aluminum cans or car bodies, are first fed into a double-shaft shredder. Its high-torque, low-speed blades tear the material into smaller, uniform pieces, preparing them for the next stage.

Step 2: Fine Crushing & Liberation (Scrap Metal Crusher)

The pre-shredded material enters the heart of the system: the scrap metal crusher. Using high-speed rotating hammers, it pulverizes the material, breaking apart composite items and liberating the aluminum from attached ferrous metals and other contaminants.

Step 3: Ferrous Metal Removal (Magnetic Separator)

After crushing, the material mix travels under a powerful overband magnetic separator. All iron and steel particles are lifted out of the material stream, leaving a mix of non-ferrous metals and non-metallic waste.

Step 4: Non-Ferrous Metal Separation (Eddy Current Separator)

This is the most critical step in any aluminium recycling plant. The remaining material is fed onto the high-speed conveyor of our eddy current separator. A powerful rotating magnetic rotor induces “eddy currents” in the non-ferrous metals (like aluminum and copper), effectively repelling them and throwing them forward into a separate collection bin. Heavier non-metallic materials simply fall off the end of the conveyor.

Step 5: Final Sizing (Trommel Screen)

A trommel screen can be used after the eddy current separator to classify the final aluminum product into different sizes based on customer requirements.

Step 6: Optional Enhancement: Rust & Paint Removal (Dry Grinding Mill)

For clients processing materials like burnt iron with aluminum attachments or requiring a mirror-finish on the final product, we can integrate a dry grinding mill. This machine tumbles the crushed metal with an abrasive agent, effectively polishing the surface to remove rust, paint, and oil, further enhancing its purity and value. This is a key component for creating premium-grade recycled materials.

Specifications of the Industrial Metal Shredding Line

While every Shuliy aluminium recycling plant is custom-designed to match your specific raw materials and throughput goals, the table below outlines typical configurations. This provides a clear overview of the operational footprint and performance you can expect from our integrated solutions.

| Name | Aluminum Recycling Plant |

| Capacity | 3 – 5 Tons per Hour (TPH) |

| Final Metal Purity | > 99% (with optional polishing) |

| Total Installed Power | Approx. 150 – 200 kW |

| Required Workshop Area | ~ 400-500 m² (5,400 ft²) |

| Required Operators | 2 – 3 Persons |

| Core Process Flow | Shredding → Crushing → Magnetic Separation → Eddy Current Sorting |

| Primary Application | Medium-sized scrap yards, automotive recyclers |

Please note: The figures above are estimates. The final power consumption, footprint, and staffing needs will depend on the exact equipment configuration chosen for your scrap metal processing line. Our engineers work with you to analyze your input materials and design a plant layout that maximizes your efficiency and profitability within your available space.

Please Free To Contact Us!

With successful cases in several countries, like Ghana, Somalia, Philipines, etc., we deliver not only single machines, but also complete solutions. From custom layout design to on-site installation and support, our team is ready to build your profitable recycling business. Contact us to get started!