Waste balers save space by compressing industrial waste. This is an environmentally friendly way to run any business. Organizations that generate waste must sort it. This helps in recycling and means less waste goes to landfills. Recycling machinery that sorts industrial waste such as paper, cardboard, plastic, and metal is certainly an asset for organizations that need it. When space is at a premium, bales must be compact. The more compact they are, the less space they will fit in.

Efficient waste disposal is the goal of every industry. Disposing waste in a safe manner is not only good for the environment but is also cost-effective for businesses. Organizations that are seen to adopt environmentally conscious processes and policies are considered more ethical than those that do not. Horizontal, vertical, mini, and medium-sized are all different types of waste balers that are available for companies to rent or lease. Each of them has its own pros and cons.

what is the difference between horizontal and vertical balers?

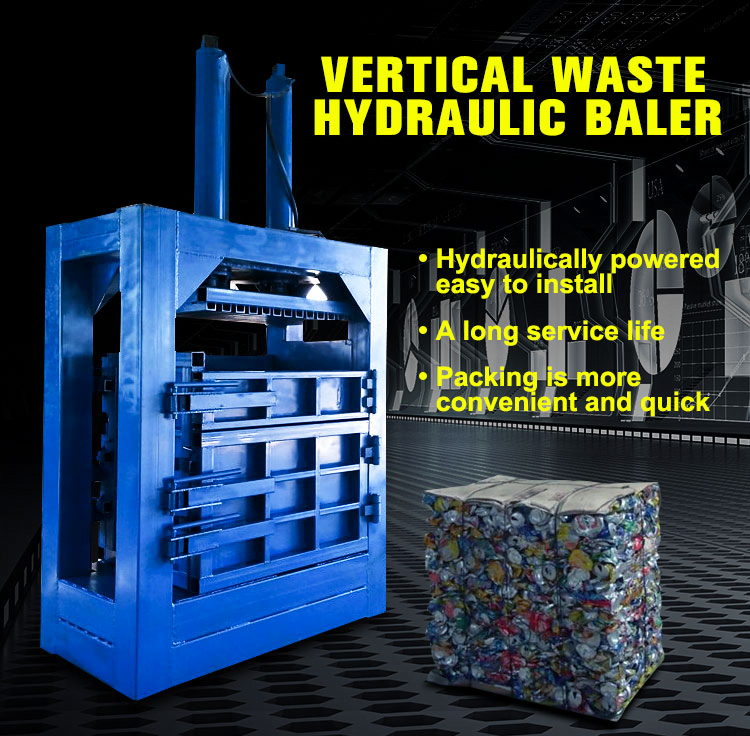

Vertical baler is better suited for smaller applications that produce less waste and require manual operation, which increases labor costs. Horizontal baler can usually handle more waste but are usually more expensive, but they are more automated. Automation can save on labor costs, which can provide long-term savings as long as you generate enough waste to make it worthwhile. Waste baling equipment can often be purchased or rented depending on requirements and circumstances. Balers come in different sizes and features, so it is important to analyze your needs before choosing which one to use. If labor-saving and high throughput of waste is a priority, a horizontal baler is a good choice.

What kind of baler is best for you?

Depending on the type of application, balers are available in horizontal, vertical, small, medium, and mill sizes. Demand, budget, cost, and labor usually determine which type of equipment a company or organization uses. Waste machinery can be rented or purchased.

Horizontal waste balers handle more waste and require less manual operation due to their semi-automatic or fully automatic operation. Vertical balers, on the other hand, are usually less expensive to purchase, but require more labor. Many companies, if they can justify the initial outlay and have enough waste volume to handle it, often choose horizontal balers because they may be the most cost-effective in the long run.

Mini balers are ideal for producing smaller bales that do not necessarily require additional specialized equipment to move to waste storage and collection points. The choice of which baler to purchase or rent ultimately depends on the requirements, but be sure to do your research before proceeding with a waste baler.

Conclusion

There are many different types of balers, and vertical balers are one of the most popular balers. Typically, vertical balers are loaded in the front and the bales are removed from the front as well. As an example of time requirements, it may take about 45 – 60 minutes to produce a 1,000 lb. bale of cardboard with a 60″ vertical baler. Since the normal workday is 8 hours, it is easy to determine the maximum amount of recyclable material the baler can actually bale each day or week by looking at the baler specifications. Vertical balers can be found in almost any type of business, including supermarkets, retailers, hotels, manufacturing facilities, distribution centers, office buildings, healthcare facilities, pharmacies, airports, and more.