Waste tires contain a significant amount of embedded steel, which makes them difficult to shred directly. Using a tire debeader machine to remove the steel bead enables the efficient separation and recycling of valuable materials, as well as enhancing overall processing efficiency and economic return. Shuliy offers a variety of tire wire drawing machines that are suitable for standard tires (900–1,200 mm) and large OTR tires (1,800–4,000 mm).

Key Features of Our Tire Debeader Machine for Sale

- Rugged, industrial-grade structure for long-term use

- High-precision hydraulic control and hook mechanism

- Easy maintenance and operator-friendly design

- Models available for both standard and extra-large tires

- Fast delivery and technical support worldwide

Parameters and Differences of Various Tire Wire Removal Machines

| Model | Single-hook Tire Debeader Machine | Double-hook Tyre Debeading Machine | OTR Tire Wire Drawing Machine |

| Hook Quantity | 1 | 2 | 1 reinforced heavy-duty hook |

| Application Tire Size | 900-1200 mm | 900-1200 mm | 1800-4000 mm |

| Working Principle | Pulls the wire from one side | Pulls steel wires from both sides | Pulls extremely thick steel rings from large OTR tires |

| Capacity | 20-30 tires/h | 40-50 tires/h | 30 pulls/h |

| Power | 11 KW | 18.5 KW | 22+3 KW |

| Structure Feature | Compact | Compact | Extra-large frame & hydraulic system |

| Tire Loading Method | Manual or semi-auto | Manual or semi-auto | Forklift or hoisting device |

| Target Users | Small recycling lines | Medium recycling lines | Heavy-duty OTR recycling facilities |

The OTR tire debeader machine is equipped with a single reinforced hydraulic hook, specifically designed to remove the extremely thick steel bead from large off-the-road (OTR) tires, typically ranging from 1800 to 4000 mm in diameter. While it technically has only one hook, this hook is significantly larger, stronger, and built for industrial-grade force—unlike the standard hooks on small debeaders.

In comparison, the single hook and double hook debeaders are made for regular car, truck, and bus tires (900–1200 mm). They are compact, easier to move, and designed for smaller-scale operations. The double hook model enhances efficiency by handling both sides of the tire at once, whereas the OTR model focuses on strength and stability for oversized, heavy-duty tires.

How Does the Tire Bead Remover Machine Work?

All of our tire debeader machines follow a similar working principle, with some variations based on model type. The typical operation process includes:

- Tire Loading: The waste tire is manually or mechanically placed onto the machine’s working table or support arm. Standard models (single/double hook) support manual loading. The OTR model requires a forklift or hoist due to tire size.

- Clamping and Positioning: The tire is clamped firmly by hydraulic pressure to prevent movement during extraction.

- Hook Insertion: A hydraulic hook is driven into the tire’s bead area to catch the embedded steel wire. Single hook model works one side at a time. Double hook model works on both sides simultaneously. OTR model uses a reinforced hook for thick steel beads

- Wire Extraction: The hook is pulled outward by the hydraulic cylinder, smoothly drawing out the steel ring.

- Unloading and Repeat: The tire (now without steel) is released and removed. The process is repeated for the next tire.

Output of the Tire Wire Extractor Machine

After wire extraction, two outputs are obtained: the steel bead wire and the rubber tire body without the steel. Each has distinct features and uses:

- Steel Bead Wire: High-strength, multi-loop steel rings with minimal rubber residue. They can be sold directly to steel mills for remelting or used as an alternative industrial fuel in some applications.

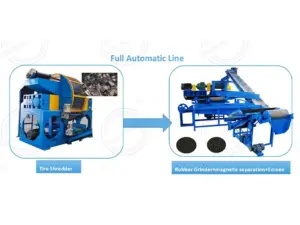

- Rubber Tire Body: Once the steel is removed, the tire can be further processed with a tire cutting machine, tire shredder, and rubber granulator. For large OTR tires, the OTR debeader can be paired with an OTR tire cutter for efficient pre-treatment.

Tire Debeader Machine for Sale

Shuliy Machinery is committed to delivering durable, high-performance tire debeader machines to global recycling businesses. Whether you’re handling standard passenger tires or giant OTR tires, we have a solution tailored to your needs. Contact our team now to get a free quote and consultation. We’ll help you choose the right model and provide full technical support for installation and operation.