Waste tires contain large amounts of hard steel wire. If fed directly into a tire shredder without prior treatment, they can easily damage the equipment. Shuliy offers two types of efficient tire steel wire separators, used for standard tires (<1200 mm) and OTR tires(>1400 mm), which accurately separate steel wires from tire scraps, enabling efficient sorting, recycling, and reuse of resources.

Why Need A Tire Steel Wire Separator?

Whether standard tires or giant mining tires, tire bead wires are made of high-strength steel, embedded in the sidewall of tires to maintain their structural integrity. However, these wires can:

-

Damage tire shredders and rubber crushers

-

Reduce the quality of rubber powder output.

-

Lower the recycling efficiency.

Using a tire wire removal machine before shredding helps:

-

Protect shredders and grinders from steel damage.

-

Improve rubber purity for granule or powder production.

-

Enable steel recycling and resource separation.

-

Support smooth, efficient tire recycling line operation.

Two Types of Tyre Steel Wire Separators

1. Standard Tire Steel Wire Separator (Model: SWS-100)

Used in semi-automatic recycling lines, this model is ideal for handling car, truck, and bus tires with diameters up to 1200 mm. It is usually paired with a tire sidewall cutter and tire shredder.

| Model | SWS-100 Steel Wire Separator |

| Motor Power | 18.5 kW |

| Capacity | 120 pcs/h |

| Input tire size | ≤1200 mm |

| Machine size | 2*1.9*1.8 m |

| Machine weight | 1800 kg |

2. OTR Tire Steel Wire Separator (for 1400–4000 mm tires)

This heavy-duty steel ring separator is engineered for OTR (Off-the-Road) tires used in mining, agriculture, and construction. It can extract thick steel bead wires from large industrial tires efficiently, which is often used with a tire dismantler machine and a tire shredder.

| Name | OTR Tire Wire Removal Machine |

| Motor Power | 35.5 kW |

| Input Tire Size | 1400–4000 mm |

| Output | 1 bead / 2-5 minutes |

| Dimensions | 3.65*2.1*1.95 m |

| Weight | 6200 kg |

| Packing | Uncrated (oversized machine) |

Key Features of Our Tire Bead Wire Remover Machine

✅ Full Compatibility:

Seamlessly integrates into both semi-automatic waste tire recycling lines and OTR tire recycling lines.

✅ Durable Structure:

Made with thickened steel frames, wear-resistant materials, and industrial-grade motors for long service life.

✅ High Efficiency:

Extracts steel wires quickly and cleanly with minimal manual intervention.

✅ Low Maintenance:

Simple structure with easy-access parts for fast inspection and repair.

✅ Customizable Design:

Support for different tire sizes, operating voltages, and conveyor connections to match your plant layout.

✅ Safe Operation:

Equipped with emergency stop, safety guards, and overload protection.

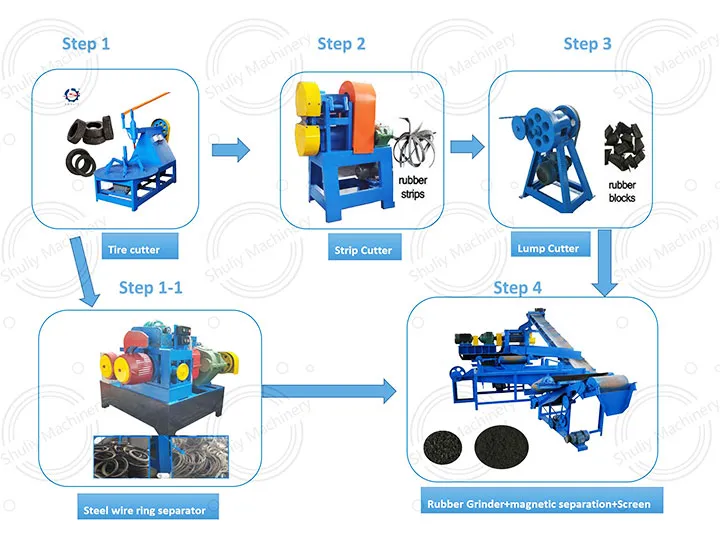

Applications in Rubber Powder Production Lines

| Machine Type | Application | Works With |

|---|---|---|

| Standard tire steel wire separator | Standard tires (≤1200 mm) | Sidewall cutter + tire shredder |

| OTR tyre steel wire separator | Engineering/off-road tires (1400–4000 mm) | Tire dismantler + tire shredder |

How does the Tire Wire Removal Machine Work?

The tire steel wire separator is designed to extract the tough bead wires embedded in the sidewalls of waste car and truck tires before shredding. Here’s how it works:

-

Manual Tire Positioning

The operator places a pre-cut tire bead (usually after cutting with a tire sidewall cutter or bead remover) into the feed area between the rollers. -

Powerful Roller Traction

The machine is equipped with two or three heavy-duty rollers driven by a strong motor (e.g., 18.5kW). These rollers grip and pull the tire bead inward. -

Wire-Rubber Separation

As the tire bead moves through the rollers, a specially designed separation blade or notch applies pressure to strip the embedded steel wire ring away from the surrounding rubber. -

Separate Collection

-

The steel wire is pulled out as a continuous or semi-continuous loop and collected separately.

-

The rubber residues fall off or are manually removed.

-

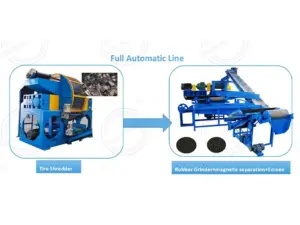

Complete Tire Recycling Solutions Available

Shuliy Machinery provides full recycling line setups including:

-

Tire sidewall removers/ OTR tire dismantler machine

-

Tire shredder for sale

-

Magnetic separators and rubber granulators

-

Fully automatic or semi-automatic configurations

Need a customized setup? Let our engineers help tailor the right solution for your business.