The semi-automatic waste tire recycling line combines manual operation with automated equipment to realize efficient and high-quality rubber powder production through pre-processing, deep shredding, grinding, and sieving. The purity of the finished rubber powder can reach more than 99%, and the adjustable particle size range is 10-40 mesh(0.63-2.5 mm), which can meet the application requirements of various industries.

Application of Rubber Powder Production Line

Small scrap tires with a diameter of less than 1200mm are usually composed of rubber, steel wire, nylon, and other materials. The rubber can be efficiently recycled through the tire recycling equipment, and the steel wire, nylon, and other impurities can be effectively separated and recycled. The particle size of the finished rubber powder can be flexibly adjusted according to the specific production requirements. The finished products are widely used in many fields such as rubber asphalt, road paving, sports track, recycled rubber products, rubber mats, and so on.

Advantages of Our Waste Tire Recycling Line

Low investment cost: the structure of the equipment is simple, the total investment is small, suitable for small and medium-sized rubber recycling factories to put into operation.

Flexible and easy operation: manually adjust the shear angle and recycling process according to different tyre materials to improve the processing efficiency.

High quality of finished products: the purity of rubber powder can reach more than 99%, the particle size range of 10-40 mesh, and support for on-demand adjustment.

Multi-purpose: support the effective classification and recycling of rubber, steel wire, nylon, and other materials to improve the overall utilization rate.

Modular design: the whole line adopts a modular structure, which can flexibly configure the equipment and accurately match different capacities and production requirements.

Environmental protection: the whole line has low energy consumption and can be equipped with CE and ISO certificates, which conform to environmental protection standards and facilitate import and export.

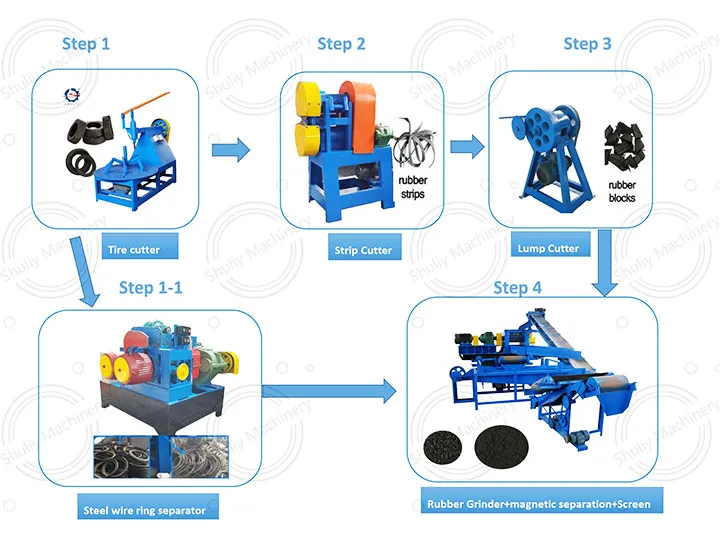

Detailed Tire Recycling Process

- Remove steel wires: The tire ring cutter cuts the edge of the tire by rotating the blade to remove the tire bead, which contains a large number of steel wire rims.

- Strip cutting: The two round blades of the strip cutter cut the tire with the bead removed into long strips 3-5 cm wide.

- Block cutting: The tire strip cutter cuts the rubber strip into small pieces of 5cm in length and width for subsequent shredding and grinding.

- Shredding: The tire shredder uses high-torque knives to further shred the tires into more uniform and easier-to-grind particles.

- Grinding and sieving: Through the repeated grinding of the double roller and sieving of screens, to produce 10-40 mesh rubber powder.

- Magnetic separation: Two magnetic separators ensure the removal of fine iron wire and other magnetic impurities in the rubber powder.

- Fiber separation: Through the air flow sorting principle to remove the mixed fibre impurities, to ensure that the purity of rubber powder is more than 99%.

Specification of each equipment

Tire Ring Cutter

| Name | Work range | Capacity | Motor power | Machine weight | Machine size |

| Tire sidewall cutter | ∅650-1200 mm tires | 40 pcs/h | 4+0.75 KW | 650 kg | 1.8*1.3*1.6 m |

Tire Strip Cutter

| Name | Capacity | Motor power | Motor speed | Output size | Machine weight | Machine size |

| Tire strip cutter | 1000 kg/h | 5.5 KW | 45 r/min | 3-5 cm wide strips | 850 kg | 1.3*0.8*1.65 m |

Tire Block Cutter

| Model | Capacity | Motor power | Output size | Machine weight | Machine size |

| QKJ-358 | 800 kg/h | 5.5 KW | 3*5*6 cm | 800 kg | 1.0*0.8*1.4m |

| Updated cutter | 1500 kg/h | 18.5 KW | 5*5 cm | 1200 kg | 1.3*1.1*1.5m |

Tire Shredder

| Model | 900 | 1000 | 1200 | 1500 | 1800 |

| Capacity | 2 t/h | 4 t/h | 5-6 t/h | 8-10 t/h | 15-20 t/h |

| Power | 64.5 KW | 94.5 kw | 157 KW | 188.5 KW | 328.5 KW |

| Blade Thickness | 50 mm | 50 mm | 60 mm | 75 mm | 100 mm |

| Footprint size | 9*5*2.8m | 10*6*3.2 m | 10*6*3.2 m | 20*10*3.5 m | 20*12*4 m |

| Machine size | 4*2.2*2.8 | 5*2.6*3.2 | 5*2.6*3.2 | 20*10*3.5 | 20*12*4 |

Tire Grinding and Screening System

| Size\Model | SL-350 line | SL-400 line | SL-450 line | SL-560 line | SL-560 D line | SL-660 line |

| 10 mesh(2.5 mm) | 250-300 kg/h | 400-500 kg/h | 500-600 kg/h | 900-1000 kg/h | 1500-1600 kg/h | 2100-2300 kg/h |

| 20 mesh(1.25 mm) | 180-230 kg/h | 300-350 kg/h | 400-500 kg/h | 600-700 kg/h | 1200-1300 kg/h | 1600-1700 kg/h |

| 30 mesh(0.83 mm) | 150-210 kg/h | 240-280 kg/h | 350-450 kg/h | 450-550 kg/h | 1000-1100 kg/h | 1200-1300 kg/h |

| 40 mesh(0.63mm) | 80-120 kg/h | 150-175 kg/h | 200-250 kg/h | 300-350 kg/h | 800-900 kg/h | 900-1000 kg/h |

Fiber Separator

| Name | Capacity | Motor power | Motor speed | Machine weight | Machine size |

| Fiber separator | 800-1000kg/h | 5.5 KW | 760 r/min | 1600 kg | 1.5*1.5*3.4 m |

Welcome to Visit Our Tire Recycling Machines!

Shuliy specialises in customising efficient and practical solutions for rubber powder production, and we sincerely welcome customers from all over the world to call or visit our factory.

Below are photos of customers from Australia, Mexico, and other countries visiting our facilities: