As the automotive and engineering industries continue to grow, the need for tire recycling increases. The tire rubber shredder for sale is important equipment for recycling.

It crushes waste tires and outputs uniform, small rubber pieces that are easy to grind, transport, store, or use as raw materials for new rubber products.

Raw Materials and Output of the Tire Shredding Machine

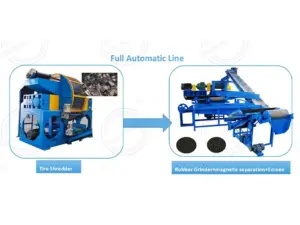

The Shuliy tire rubber shredder for sale comes in various models and sizes, offering flexibility to adapt to different production needs and applications. The crusher can process all types of tires, including automotive, construction (OTR), and large OTR tires. Both automatic and semi-automatic rubber powder production lines can be adapted accordingly.

The industrial tire shredder can process the following forms of raw material:

- Whole tires (up to 1400 mm in diameter)

- Disintegrated or de-wired tire parts

- Cut tire segments or strips

The size of the shredded rubber pieces can be adjusted by changing the screen. A typical output range is 50-100 mm to accommodate different subsequent processing requirements.

Key Features of the Rubber Shredder for Sale

-

Wide Application: Suitable for all types of waste tires, including car, truck, OTR tires, etc.

-

Powerful Shredding: High torque, low speed design ensures strong, efficient performance.

-

Robust Structure: Heavy-duty frame built for continuous and stable operation.

-

Uniform Output: Clean, evenly sized rubber blocks ideal for further processing.

-

Adjustable Screen: Output size adjustable (typically 50–100 mm); screen is easy to replace and maintain.

-

Reliable After-Sales: Warranty provided with optional on-site installation and technical support.

List of Rubber Shredding Machines

A professional waste tire shredder designed to cut all types of tires into uniform rubber blocks (50–100 mm), ideal for recycling, grinding, or alternative fuel use. These tyre crushers are available in multiple models to meet your production needs.

| Model | SL-900 | SL-1000 | SL-1200 | SL-1500 | SL-1800 |

|---|---|---|---|---|---|

| Capacity | 2 tons/h | 4 tons/h | 5–6 tons/h | 8–10 tons/h | 15–20 tons/h |

| Input Size | ≤900 mm | ≤1000 mm | ≤1200 mm | ≤1200 mm | ≤1400 mm |

| Output Size | 50 mm | 60 mm | 60 mm | 75 mm | 100 mm |

| Motor Power | 64.5 kW | 94.5 kW | 157 kW | 188.5 kW | 328.5 kW |

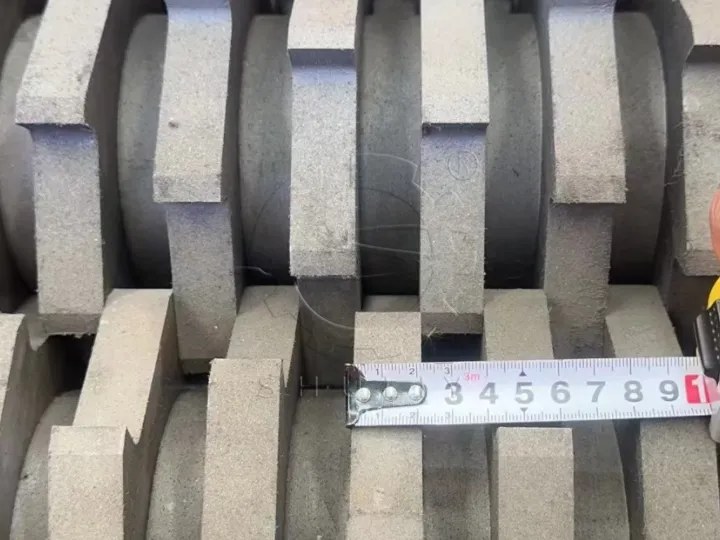

| Blade Specs | 360 mm Ø / 50 mm thick / 16 pcs | 440 mm Ø / 50 mm thick / 16 pcs | 510 mm Ø / 60 mm thick / 18 pcs | 580 mm Ø / 75 mm thick / 20 pcs | 650 mm Ø / 100 mm thick / 18 pcs |

| Machine Weight | 10 tons | 13 tons | 15.8 tons | 18.6 tons | 26 tons |

| Footprint | 9*5*2.8 m | 10*6*3.2 m | 10*6*3.2 m | 20*10*3.5 m | 20*12*4 m |

| Conveyor Size | 7200*950 mm | 7200*1150 mm | 7200*1350 mm | 7200*1350 mm | 7200*1550 mm |

| Blade Material | Alloy steel composite | Alloy steel composite | Alloy steel composite | Alloy steel composite | Alloy steel composite |

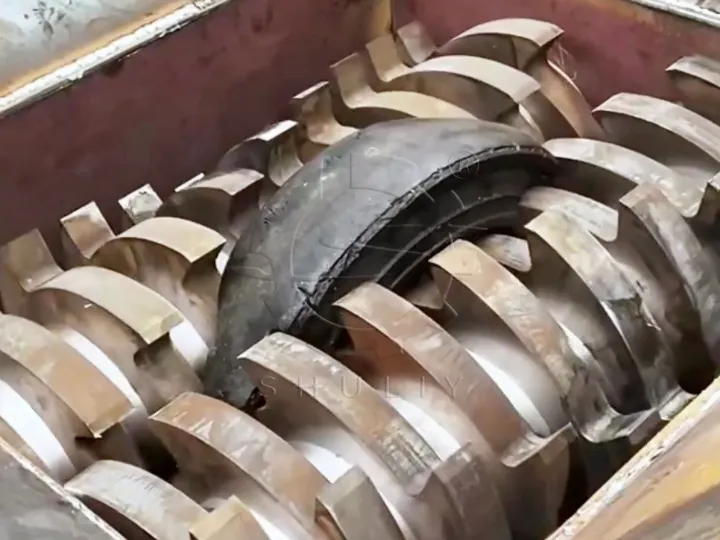

Working Principle of the Tire Shredder Machine for Sale

This rubber shredder for sale adopts a dual-shaft shearing design to efficiently break down scrap tires. A key feature is its external rotary screen—oversized materials that don’t meet the set output size will be rotated back into the hopper and shredded again, ensuring consistent granularity and minimizing manual handling.

Driven by a low-speed, high-torque motor, the machine offers powerful cutting force, reduced wear, and long service life. This design makes it ideal for waste tire shredder systems, industrial rubber recycling, and starting or expanding a tire shredding business. It can also work in combination with tire granulators for further size reduction.

Start Profiting from Tire Waste Today

Our advanced rubber tire shredders help you turn scrap tires into valuable materials with ease and efficiency. Contact our expert team via WhatsApp: +86 17303831295 for a free consultation and machine quote!