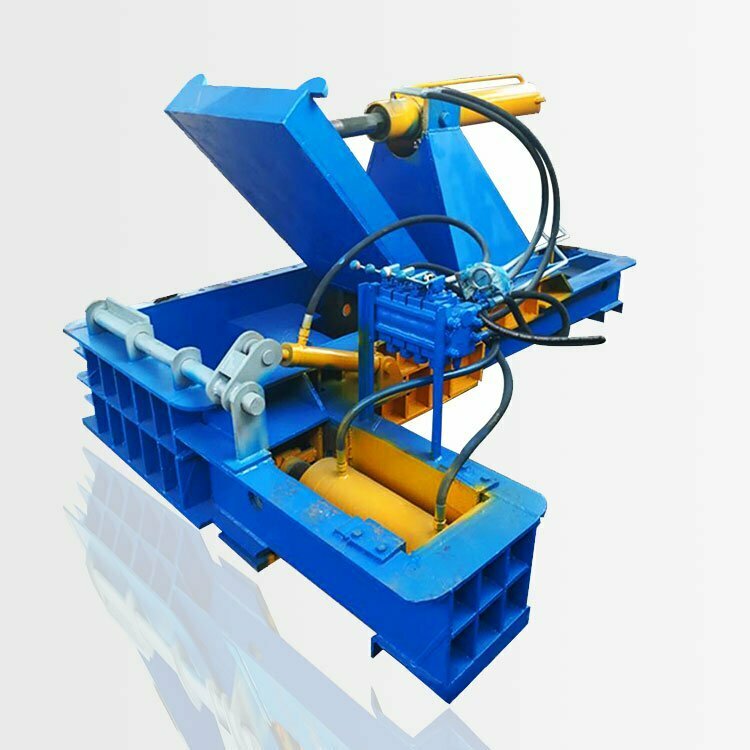

Scrap metal baler has wide applications in the waste metal recycling processing industry and metal smelting industry, suitable for various large, medium, and small steel mills. It can extrude various kinds of metal scraps into cuboids, cubes, polyhedrons, cylinders. The applicable raw materials include metal scrap, steel shavings, scrap steel, scrap iron, scrap copper, aluminum scrap, aluminum shavings, dismantled car shells, cans, aluminum alloy, waste oil barrel, etc. After compressing, the machine can turn the metal bale out by side or forward. The compressed waste metal is convenient to store, transport, and smelt.

Working procedure for scrap metal baler

Feeding automatic metal material to the compression chamber → the door steel cover plate pressing down and locked → the back press plate pressing forward by hydraulic cylinder → the side pressure plate pressing to the other side → the block is formed at a certain shape→ the steel cover plate lift → the block turn device turns compressed metal material out → the cylinder reset → the whole process is completed

Features & benefits of the metal baler

- Hydraulically driven, work smoothly, safe and reliable

- The scrap metal baler adopts manual or PLC automatic control.

- The discharge form includes four types, side-turn metal block, side-push block, forward push, and forward turn optional.

- The installation does not require foot screws, and the diesel engine can be used in a place where there is no power supply.

- Compact structure, simple operation, easy maintenance, reliable sealing, convenient loading, and unloading,

- The equipment improves labor efficiency, reducing labor intensity, saving manpower, and reducing transportation costs.

- Users can customize the packing specifications and sizes according to their needs in order to maximize cooperation with transportation or storage.

Scrap metal baler for sale in Shuliy Machinery

The hydraulic waste metal baler has 10 varieties and more than 20 specifications from 63tons to 600tons, which can meet different customers’ demands. Different specifications of the hydraulic metal balers are equipped with different bin sizes, compressed sizes, molding time, power, and price, etc. You can choose according to your actual needs, or get in touch with us to get professional suggestions. Besides, we also support customization services. It means we can customize the metal baler machine in accordance with your specific requirements for the equipment. We will do our best to provide the best service for you.

What should you consider when purchasing a scrap metal baler?

In order to choose and purchase a suitable metal baler, it’s better to take these things into account as follows.

- Which metal material do you want to compress into the block? Different materials require different power, bin sizes, and molding time, etc.

- What is the size of the metal block you want to get? The compressed size has an effect on the space of storage and transportation.

- How about the size of compressing space? The bin size determines its compressed size, so you can choose a suitable metal baler machine based on the compressing space.

- How many tons of pressure? The more weight metal material requires more pressure. And the bigger pressure can compress the metal material more compact.