An EPS pelletizing machine is a special recycling machine for crushing and granulating the waste styrofoam, or expandable polystyrene (EPS). The EPS pelletizer has a reasonable design, high degree of automation, advanced technology with no pollution. The plastic particles produced are uniform in size and brightness. The granules produced are widely used, such as wall insulation materials, product packaging materials, and auxiliary materials for some products.

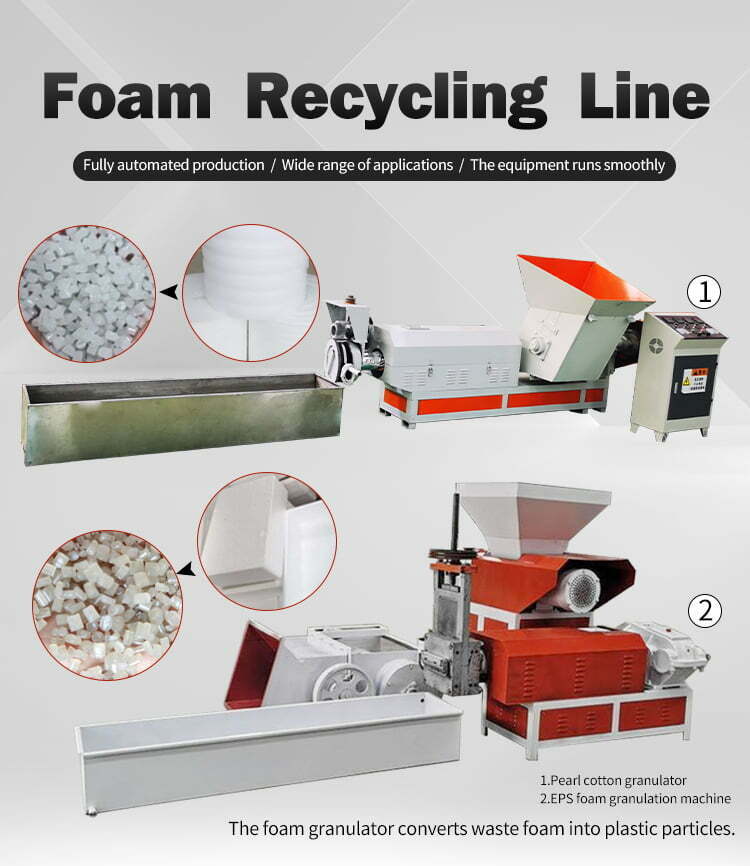

Nowadays, the amount of expandable polystyrene (EPS) is increasing rapidly. These waste polystyrene foam plastics are lightweight, bulky, aging-resistant, and difficult to corrode, so they have become a major problem in garbage disposal. In recent years, EPS foam recycling has attracted more and more attention, and the recovery of foamed polystyrene has broad prospects. EPS pelletizer machines are often used in plastics recycling lines and become more and more popular in the recycling industry. Besides the EPS foam granulation machine, we also offer EPE/Pearl cotton granulators.

EPS pelletizer machine application

The EPS foam granulation machine is used to process styrofoam from waste fast food boxes, household appliances, styrofoam packing materials for delivery protection, and so on so that it can be transformed into recycled EPS pellets. plastic foam processed by EPS melt densifier is also applicable. This recycled plastic can be used to produce various insulation materials,packaging materials, toys, and electrical appliances, and so on.

Outstanding advantages of EPS pelletizing machine

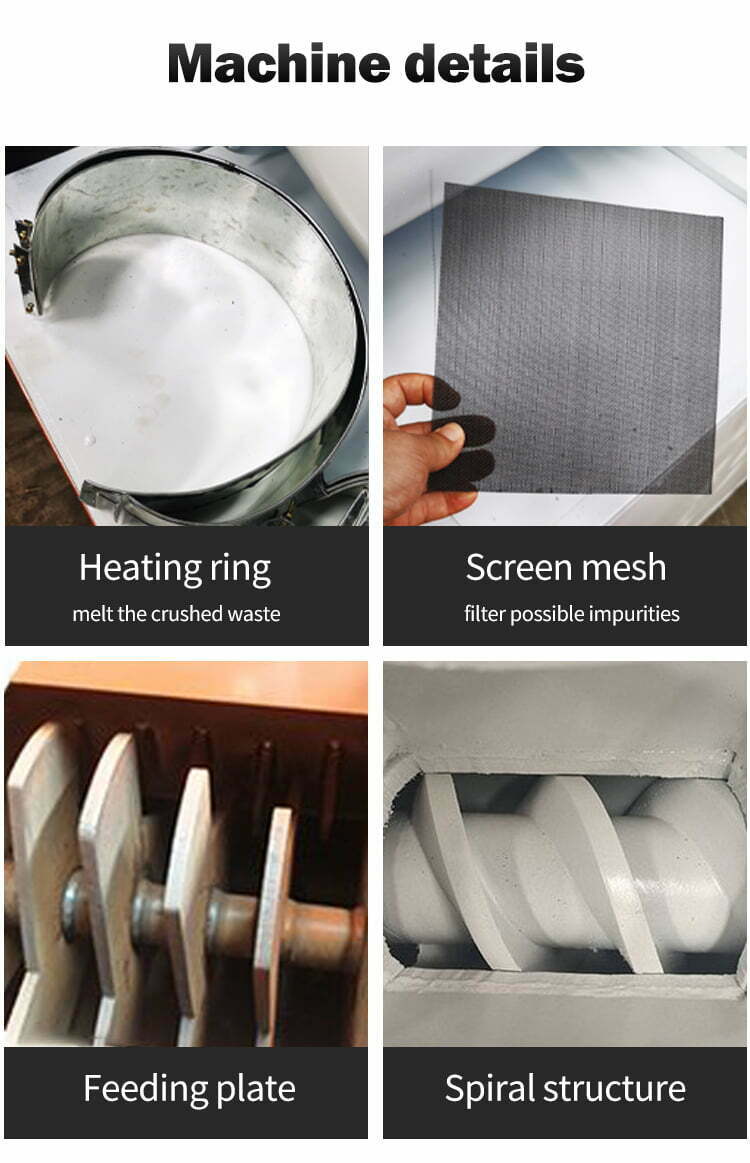

1. The main and auxiliary machine screws are made of heat-treated 45# steel. It has good comprehensive mechanical properties.

2. The motor is equipped with two gear reducers, which realize stable operation and keep long service life.

3. The EPS foam granulator adopts a conical screw barrel, which has a high feed rate and high output.

4. The main and auxiliary machines are used together for supporting production. The heating temperature is stable, the material molecular structure is effectively improved, the air permeability is enhanced, and the particle quality is significantly improved. The main engine temperature is 200 Celsius degrees, and the auxiliary engine temperature is 180 Celsius degrees.

5. There are two heating methods for option. Electromagnetic (heating time 10-15 minutes), electric heating tube / electric heating ring (30-40 minutes)

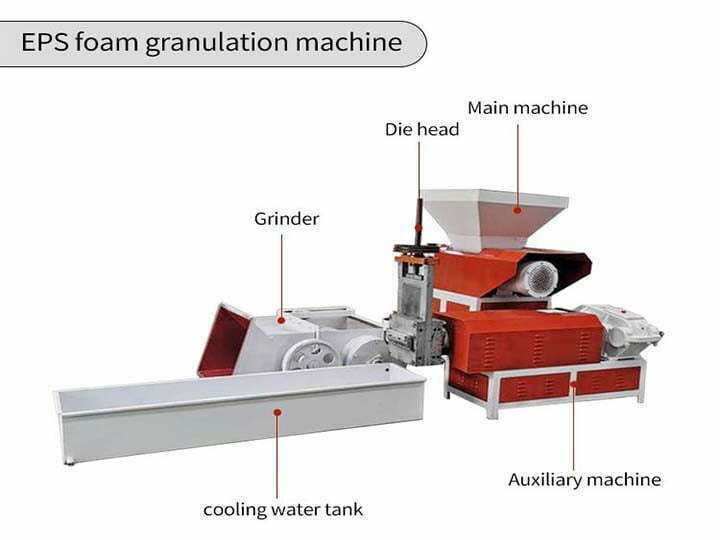

6. EPS foam granules making machine mainly comprises the crushing part, main and auxiliary engines, the electric mold.

7. Adopt electric screen changing mold without interruption to reach high production efficiency.

8. The EPS pelletizing machine is often collocated with a foam crusher, water cooling tank, and plastic grain cutting machine, which are all often used in foam recycling lines.

EPS pelletizer working principle

The eps pelletizing machine is completed by the process of grinding, plasticizing, stripping, and granulating the foam. The main function of this machine is to dissolve the old froth after being crushed by the foam crusher, to make the small granules through the process of plasticizing, strip cutting, and grain cutting. so as to facilitate regeneration and reuse.

Video of EPS granulation machine

Parameter of EPS pelletizer machine

The model of the EPS pelletizing machine is based on different diameters of the screw shaft. For specific needs, we also provide customized services.

| Model | Specification |

| Model: 220+150

|

Pellet making machine with crusher

Power:15kw+5.5kw Capacity:150-200kg/h Double gear reducer |

| Model: 270+150

|

Pellet making machine with crusher

Power:18.5kw+5.5kw Capacity:200-250kg/h Double gear reducer

|

| Model: 320+180

|

Pellet making machine with crusher

Power:18.5kw+11kw Capacity:250-300kg/h Double gear reducer |

| Model: 350+180

|

Pellet making machine with crusher

Capacity:250-300kg/h Double gear reducer |

Related machines

- foam crusher machine

- water cooking tank

water cooling tank Another kind of foam pelletizer machine