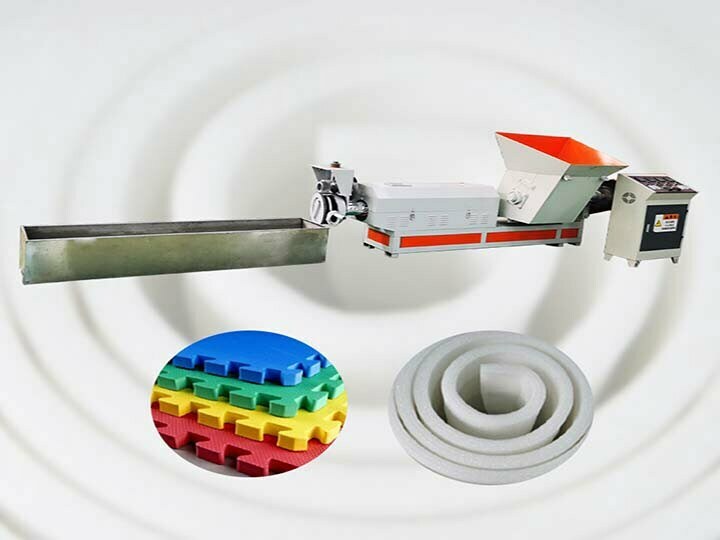

EPE foam pelletizer is mainly used for pelletizing waste pearl cotton, expandable polyethylene foam packages, insulation materials, electric appliances outer part, and other EPE foam waste. EPE foam recycling machine is designed to process waste EPE pearl cotton materials into particles, which can be used for re-processing and utilization. The whole pelletizing set mainly includes waste foam smashing, plasticizing, cooling, grain cutting. The EPE/PE foam recycling machine has the features of reasonable design, high automatic degree, stable operation, and wide application.

Introduction to EPE foam

EPE (expandable polyethylene) is also known as pearl cotton. EPE foam is a new environment-friendly packaging material. It is composed of many independent bubbles generated by the physical foaming of low-density polyethylene grease. It overcomes the shortcomings of ordinary EPS foam, such as friability, deformation, and poor recovery. It has the advantages of waterproof and moisture-proof, shockproof, sound insulation, thermal insulation, good plasticity, strong toughness, recycling, strong anti-collision, and also has good chemical resistance.

As an ideal substitute for traditional packaging materials, EPE foam or pearl cotton is widely used in the packaging of a wide range of materials, such as electronic products, industrial equipment, handicrafts, glass, ceramics, household appliances, furniture, wine, and gift packaging, toys, fruits, daily necessities, and other products.

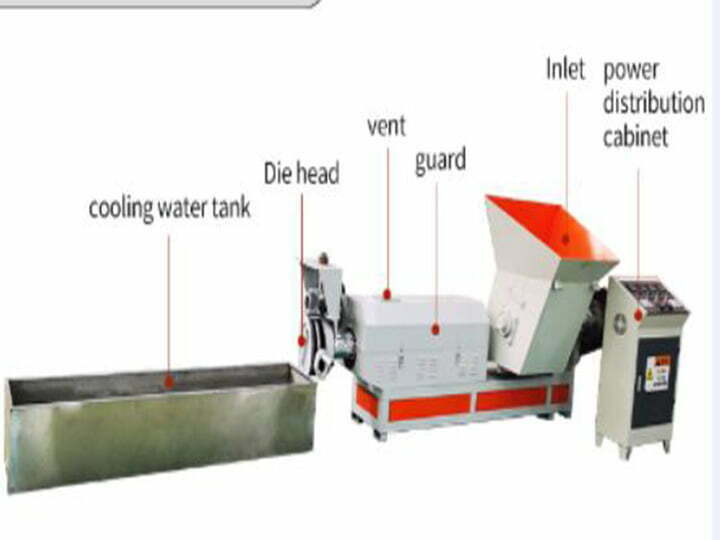

EPE foam pelletizer structure

The EPE foam pelletizing machine mainly contains the inlet, the gear reducer, vent, heating part, die head, power distribution cabinet, etc.

Highlights of pearl cotton foam pelletizer

The pearl cotton foam pelletizer machine has many advantages and is often used in recycling lines.

- The EPE foam pelletizer adopts a conical screw barrel with a fast feeding speed

- Automatic temperature control, stable heating temperature. The temperature reaches about 200 Celsius degrees.

- Hard gear surface reducer, ensuring stable operation with low noise and long service life.

- The regenerated particles can effectively improve the molecular structure of the material, and the processed plastic has a good finish, smooth surface, and no pores.

- Electromagnetic and electric heating rings heat up rapidly and have a good thermal insulation effect.

- The electric mold changing die can automatically change the mold without stopping the machine, realizing high production efficiency.

- The strips pulled out are uniform and can be paired with the integrated grain cutter machine to complete pelletizing.

- Multiple models are available. Common specifications: SL-160 and SL-180.

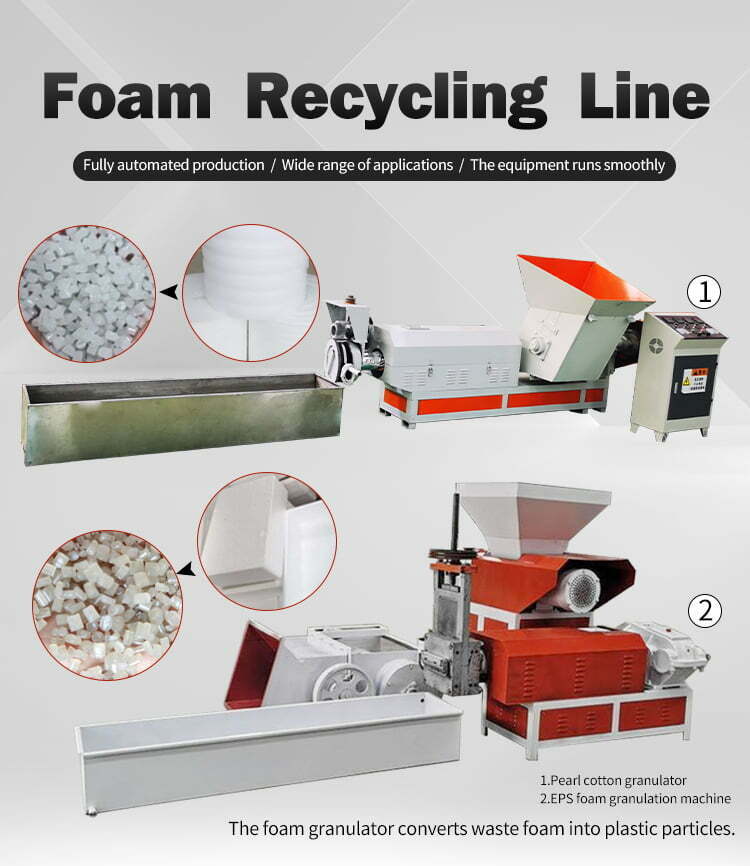

The main difference between EPE pelletizer and EPS pelletizer

The EPE foam pelletizer adopts an integrated structure design, combining the main and auxiliary pelletizing equipment together, while the EPS pelletizing machine involves both parts.

Parameter (SL-160)

| Model | SL-160 |

| Machine size | 3400*2100*1600mm |

| Inlet size | 780*780mm |

| Power | 30kw |

| Capacity | 150-200kg/h |

| Heating method | Heating ring |