Building a profitable metal recycling operation requires more than just a good separator; it requires a perfectly synchronized system where every machine works in harmony. A bottleneck at the start or a poorly matched output conveyor can cripple the efficiency of even the best eddy current sorter.

At Shuliy, we specialize in designing and delivering complete, turnkey eddy current separation systems. We look at your entire process—from initial input to final sorted product—to create a fully integrated recycling solution that guarantees optimal performance and a higher return on investment.

Anatomy of a Shuliy Separation System

A truly efficient integrated sorting system is composed of several key stages, all supplied and calibrated by Shuliy to work together seamlessly.

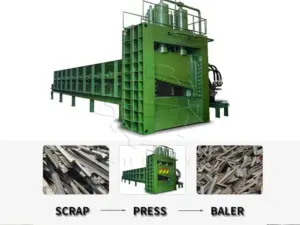

- Infeed & Spreading (Preparation): It starts with a Vibrating Feeder to receive bulk material and spread it into a thin, even layer. This is crucial for the downstream equipment to work effectively.

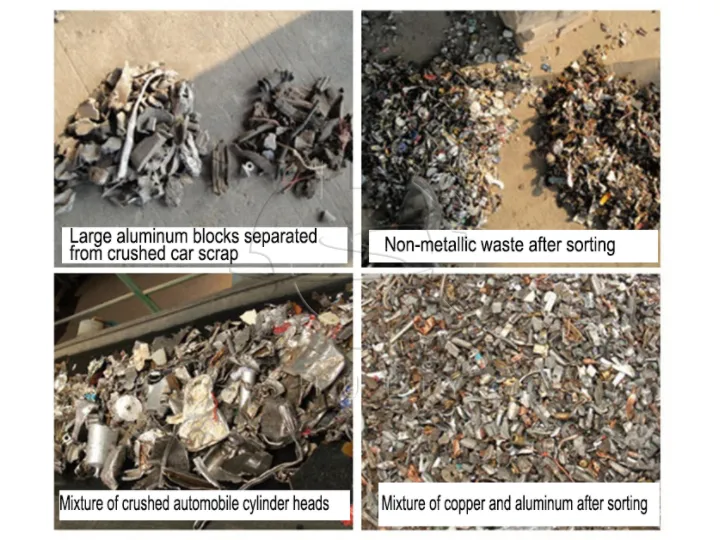

- Ferrous Metal Removal (Purification): Next, a powerful Overband Magnet or Magnetic Drum removes all iron and steel contaminants. This protects the eddy current separator and purifies the material stream.

- Non-Ferrous Separation (The Core): The material then flows into the heart of the system: the Shuliy Eddy Current Separator. This machine uses its high-speed rotor to powerfully eject all non-ferrous metals like aluminum, copper, and brass.

- Material Handling (Output): Finally, a series of Conveyor Belts are configured to carry the separated streams—one for clean non-ferrous metals and another for the remaining inert materials—to their designated collection areas.

Why Choose an Integrated Shuliy System?

Opting for a complete Shuliy eddy current separation system offers advantages that buying individual components cannot match.

- Guaranteed Compatibility: We eliminate the guesswork. Every machine in the system is sized and configured to match the throughput of the others, preventing bottlenecks.

- Simplified Procurement: You work with one expert supplier for the entire line. This simplifies communication, purchasing, and project management.

- Optimized Performance: Our engineers design the layout for maximum efficiency, ensuring smooth material flow and minimal drop-offs between stages.

- Unified Support & Service: When you need support, you make one call. We provide comprehensive service for the entire non-ferrous recovery line, not just a single part.

Core Separator Specifications

The heart of every Shuliy separation system is our robust eddy current separator unit. The specifications for our core models, which are integrated into our systems, are as follows:

| Model | Rotor Speed(r/min) | Belt Width(mm) | Capacity(t/h) | Power(kW) | Weight(kg) | Dimensions(mm) |

| SL-600 | 0-3000 | 650 | 4-6 | 4.0+0.75 | 1400 | 2980*1883*1210 |

| SL-800 | 0-3000 | 850 | 6-10 | 5.5+1.1 | 1800 | 2980*2033*1210 |

| SL-1000 | 0-3000 | 1050 | 10-12 | 7.5+1.5 | 2200 | 2980*2233*1210 |

| SL-1200 | 0-3000 | 1250 | 12-15 | 11+2.2 | 2400 | 2980*2433*1210 |

Note: Total system throughput and footprint will be customized based on the final integrated line design, which includes feeders, conveyors, and other machinery.

Start Designing Your System Today

Stop trying to piece together a solution. Let the experts at Shuliy design a complete, high-performance eddy current separation system tailored to your specific materials and business goals. Contact us today for a free consultation and take the first step towards building a more profitable recycling operation.