The Shuliy steel bar straightening machine is built for precision and speed. It straightens and processes steel bars efficiently, ensuring perfect alignment and high productivity. Compact, energy-efficient, and durable, this rebar straightening machine is trusted by steel plants, construction companies, and recycling facilities around the world.

Raw Material and Finished Product

The steel rod straightening machine works perfectly with steel bars, round rods, and rebars—whether made from new billets or recycled scrap.

After straightening, every piece is smooth, uniform, and free from bends or kinks. This makes it ideal for downstream processes such as bending, cutting, or welding. Ensuring consistent quality helps reduce material waste and improve overall project precision.

Key Advantages of Our Steel Bar Straightening Machine

- High Efficiency: Up to 20 straightening cycles per rod deliver consistent, fast results.

- Wide Range: Handles steel bars from 6mm to 25mm, suitable for small workshops and large-scale construction projects.

- Durable Design: Heavy-duty frame and reliable motor system (4–15kW) ensure long-term operation with minimal maintenance.

- High Accuracy: Multi-hole straightening system (5–6 holes) corrects deviations without affecting the rebar’s integrity.

- Energy Saving: Optimized mechanical balance minimizes energy use and operational cost.

Structure and Working Principle

Each Shuliy rebar straightener features a precision roller system aligned within a robust frame. The steel rod passes through several straightening holes, each stage gradually correcting its curvature.

How it works:

- Feeding: Bars are inserted manually or via automatic feeding.

- Straightening: Rotating rollers apply gradual pressure to remove deformations.

- Output: The perfectly straightened bars exit, ready for further processing or direct use.

This multi-pass system ensures stable performance, low vibration, and minimal residual stress on the rebar.

Technical Parameters

| Model | Rod Diameter | Straightening Holes | Straightening Times | Straightening Length | Motor Power | Machine Weight | Dimension |

|---|---|---|---|---|---|---|---|

| SL-6-10 | 6–10mm | 5 holes | 20 times/time | 500–2000mm | 4kW | 570kg | 1100×720×1150mm |

| SL-6-14 | 6–14mm | 5 holes | 20 times/time | 500–2000mm | 5kW | 730kg | 1200×789×1220mm |

| SL-8-16 | 8–16mm | 5 holes | 20 times/time | 500–2000mm | 5kW | 750kg | 1250×820×1300mm |

| SL-14-25 | 14–25mm | 6 holes | 20 times/time | 500–2000mm | 15kW | 980kg | 1550×890×1600mm |

Applications

The steel bar straightening machine plays a vital role across multiple sectors:

- Construction Industry: Straightens rebars for concrete reinforcement, ensuring precision alignment in building frameworks.

- Steel Processing Plants: Used for preparing steel rods before cutting, bending, or welding.

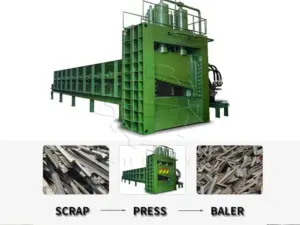

- Scrap Metal Recycling: Processes used or deformed rebar into reusable, high-quality steel rods.

- Manufacturing Workshops: Prepares straight steel materials for machinery, furniture, or hardware production.

- Infrastructure Projects: Ideal for bridges, highways, and tunnels where strict material specifications are required.

With its versatility and consistent performance, it has become an essential piece of rebar processing equipment for global steel suppliers.

Role in a Complete Rebar Processing Line

In a full steel bar processing line, the straightening machine acts as the first stage of precision preparation:

- Wire or rod feeding – Coiled or bent steel bars are loaded.

- Straightening (by Shuliy machine) – The steel is straightened for a uniform diameter and perfect linearity.

- Cutting and Bending – After straightening, the rods move to cutting or bending machines for forming rebar shapes.

- Bundling and Storage – Finished rebars are bundled and stored for delivery or direct use.

By providing stable and precise output, the Shuliy steel bar straightening machine ensures the entire production line runs smoothly, minimizing downtime and improving final rebar quality.

FAQ

Q1: What sizes of rebar can this machine handle?

A: It covers a range from 6mm to 25mm, depending on the model.

Q2: Can it process recycled or bent rebars?

A: Yes. The machine is suitable for both new and recycled rebars, ensuring uniform straightening and reusability.

Q3: Is it suitable for automatic production lines?

A: Absolutely. It can be integrated with rebar cutting or bending machines to form a complete automated rebar processing line.

Q4: How about maintenance?

A: Simple lubrication and periodic roller cleaning are enough. The design minimizes wear and requires little maintenance.

Q5: What’s the delivery time?

A: Standard models are ready for shipment within 7–15 working days, with customization available upon request.

Why Choose Shuliy

Shuliy has decades of experience in rebar processing machinery. Every steel bar straightening machine is factory-tested for durability, safety, and precision. With global service support and customized solutions, we help customers streamline production, reduce labor, and maximize profitability.