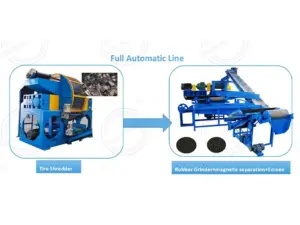

Every scrap tire represents a challenge—and an opportunity. For businesses ready to look beyond the waste, there’s incredible value locked inside that rubber. We built the tire grinding machine that seizes that opportunity. This isn’t just another piece of equipment; it’s a complete system, a powerful rubber granulator designed to turn a disposal problem into high-demand, profitable rubber powders.

From Scrap Rubber to Refined Resource

The journey from a pile of scrap to a valuable commodity is a process of refinement. Our tire grinding machine is at the heart of that transformation.

- What Goes In? The system is engineered to tackle pre-processed tire blocks, typically between 30-100mm.

- What Comes Out? Pure, uniform, and incredibly versatile rubber powder. You control the output, producing anything from 5 to 40 mesh granules, ready for the market.

Of course, you can’t feed a whole truck tire directly into a grinder. That’s why a complete system often starts with a powerful pre-processing step. If you’re dealing with whole scrap tires, our heavy-duty tire shredder machine is the workhorse you need to create the perfect input material for this grinding line.

Why Our Tire Grinding Machine Stands Out?

In this industry, performance and reliability are everything. We focused on the details that matter to your bottom line.

It’s All About Performance and Purity. First, let’s talk about power and speed. This isn’t a machine that just gets the job done; it sets the pace for your entire operation, with models capable of processing well over 2,000 kg per hour. But speed is nothing without quality. That’s why we integrated a multi-stage magnetic separation process. It’s relentless, pulling out over 99.9% of the steel wire. The result? A clean, metal-free rubber powder that commands a higher price. No compromises.

Built to Last. Downtime costs money. We know this. That’s why our tire grinding machine is constructed from heavy-gauge steel and features critical components, like the crusher blades, made from highly wear-resistant alloys. This is a machine built for the daily grind, designed for continuous operation shift after shift, year after year.

A Look Inside: The Grinding and Purification Process

Understanding how the rubber granulator works reveals the smart engineering behind its efficiency. Let’s walk through the process, which is fully automated to minimize labor and maximize output.

- Feeding & Grinding: It starts at the Main Feeder, which delivers tire blocks into the Rubber Crusher. This is where the heavy lifting happens, as the blocks are sheared and ground into smaller particles.

- Sizing and Sorting: The mix is then sent to the Main Vibrating Screen. Think of it as the system’s quality control expert. Particles of the correct size pass through. Anything too large is automatically sent back to the crusher for another pass. It’s a closed-loop system that ensures consistency.

- Purification: Next, the material flows over the Rough and Fine Magnetic Separators. These powerful magnets are crucial, efficiently stripping away every last bit of steel fiber.

- Final Polish: A Vice Vibrating Screen gives the material one last check, ensuring the final rubber powder meets your exact mesh specification before heading to the Outlet.

Technical Specifications of Tire Grinder for Sale: Find Your Perfect Fit

Your production needs are unique. That’s why we offer a full range of models. Whether you’re a startup or a large-scale recycling facility, there’s a rubber powder production machine in our lineup that’s built for you.

| Model | key Feature | Output: 10 Mesh (kg/h) | Output: 20 Mesh (kg/h) | Output: 30 Mesh (kg/h) | Output: 40 Mesh (kg/h) |

| SL-350 | Compact & Efficient | 250-300 | 180-230 | 150-210 | 80-120 |

| SL-400 | Balanced Performance | 400-500 | 300-350 | 240-280 | 150-175 |

| SL-450 | Most Popular | 500-600 | 400-500 | 350-450 | 300-350 |

| SL-560 | High Throughput | 900-1000 | 600-700 | 450-550 | 300-350 |

| SL-560D | Enhanced Capacity | 1500-1600 | 1200-1300 | 1000-1100 | 800-900 |

| SL-600 | Maximum Performance | 2100-2300 | 1600-1700 | 1200-1300 | 900-1000 |

Ready to Build Your Tire Recycling Business?

The numbers speak for themselves. The engineering is solid. The only missing piece is your business. If you’re serious about turning scrap tires into a profitable venture, let’s talk.

Contact our team today. We’ll help you configure the perfect tire grinding machine for your goals and provide a detailed, no-obligation quote!