Shuliy’s heavy-duty scrap steel shredder is engineered to convert bulky, low-value ferrous scrap into high-density, clean feedstock. By optimizing the size and purity of your steel, this machine directly improves furnace charging efficiency and reduces melting energy costs. Invest in a solution that turns HMS (Heavy Melting Scrap) and car shells into premium, high-profit commodities.

Why Leading Scrap Yards Choose the Shuliy Scrap Steel Shredder

When processing dense steel, “good enough” isn’t enough. Shuliy equipment is built for the specialized demands of the ferrous recycling industry:

- Extreme Impact Force: Our industrial steel shredder uses a high-mass, solid rotor that generates massive kinetic energy to crush rebar and thick plate steel effortlessly.

- Extended Component Life: We use custom-heat-treated alloy steel for all wear parts. This means more tons processed between maintenance cycles compared to standard shredders.

- Copper-Core Efficiency: High-efficiency motors (IP55 rated) ensure maximum torque output while keeping energy consumption significantly lower than older hydraulic models.

- Space-Saving Design: Despite its power, the machine features a compact footprint, allowing for easy integration into existing scrap yards or recycling centers.

Technical Specifications & Custom Options

Choose the right model to match your specific throughput needs. All models are built with the same industrial-grade components and can be customized with Siemens motors or specialized rotors for unique applications.

| Model | Power (kW) | Rotor Speed (r/min) | Capacity (kg/h) | Dimensions (mm) |

| SL-600 | 18.5-22 | 860 | 600-800 | 2000*1200*1900 |

| SL-800 | 30-37 | 860 | 800-1000 | 2200*1500*2200 |

| SL-1000 | 55-75 | 860 | 2500-3500 | 2800*1900*3100 |

| SL-1300 | 90-110 | 750 | 3500-5000 | 3500*2100*3800 |

| SL-1600 | 110*2 | 750 | 4000-8000 | 4400*2500*4200 |

| SL-1800 | 160*2 | 650 | 8000-12000 | 4700*2900*4500 |

| SL-2000 | 220*2 | 650 | 10000-18000 | 5000*3200*4600 |

Note: The final discharge size for all models is adjustable from 3 cm to 10 cm to meet specific buyer requirements.

Application Range and Finished Product Quality

The Shuliy scrap steel shredder is a versatile workhorse for any metal recycling facility. It excels at processing materials that standard crushers struggle with.

Primary Raw Materials:

- Industrial Scrap: Rebar, I-beams, steel drums, and thick metal stampings.

- Automotive Waste: Car shells, chassis components, and bicycle frames.

- Construction Scrap: Steel window frames, metal roofing, and demolished structural steel.

- Baled Material: Light-gauge steel bales and compressed appliances.

The Result:

The output is a uniform, high-density commodity. This “shredded steel” is highly sought after by steel mills because it improves furnace efficiency, yields a purer melt, and commands a higher market price.

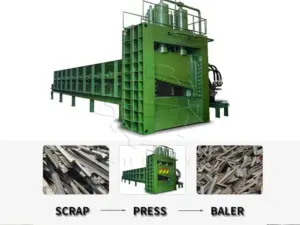

Working Principle: Engineered for Power

- Feeding: Bulk scrap is loaded via a heavy-duty conveyor into the reinforced intake.

- Impact Crushing: The high-speed rotor swings hardened hammers that strike the steel with massive force, fracturing it against the inner liner plates.

- Tearing & Scrubbing: The material is repeatedly struck and rubbed, removing impurities like paint and dirt until it reaches the desired size.

- Sized Discharge: Only material that fits through the alloy sieve plate (3-10cm) is discharged, ensuring consistent quality every time.

Scale Your Operation with a Full Shuliy Production Line

For maximum efficiency, integrate your scrap steel shredder into a complete automated system including magnetic separators, eddy current separators (for non-ferrous), and dust collection to keep your facility clean and compliant.

Upgrade Your Steel Processing Today

Ready to increase your output and material grade? Contact Shuliy Machinery for a personalized consultation. Our engineers will help you select the right scrap steel shredder configuration to match your specific volume and material type.