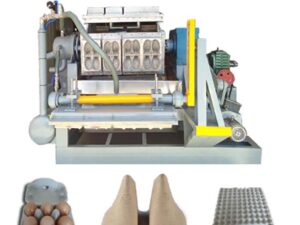

Apple tray making machine, as the name suggests, is a machine designed to produce paper trays for apple and other fruits. Of course, not only fruit trays, but other shoe trays, egg trays, egg boxes, coffee trays, etc. are also available. The machine is exquisite in design, reasonable in structure, stable in performance, and high in quality. This machine is environmentally friendly because the apple trays produced with this machine are paper trays. The raw materials used in the production of paper trays are waste paper, waste magazines, waste paper boxes, and other paper materials, which are used and reused. If you are in this industry, it can bring you great profits. Welcome to your inquiry at any time!

Main Models for Sale

According to different standards, apple tray making machines can be classified as follows:

Based on the different capacities, it can be divided into small, medium, and large capacities. The small output is about to produce 1000pcs and 1500pcs paper trays per hour. The medium one is about 2000pcs to 4000pcs per hour. The large output is above 4000pcs paper trays per hour.

In accordance with the different drying methods, the apple tray machine is divided into semi-automatic and fully automatic. The semi-automatic drying method is natural drying and trolley drying. Fully automation includes two types: brick kiln drying and metal drying. Between these two, brick kiln drying requires customers to build their own brick kilns by themselves, but we can provide professional technical guidance for customers on the basis of their needs.

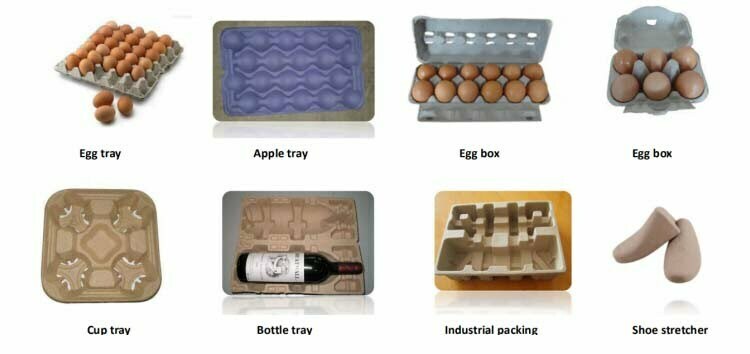

End Products of Apple Tray Machine

Although it is an apple tray machine, it can not only produce apple trays. The most important part of this machine is the molding machine, which can produce the paper trays you need through dies. For example, if you are currently operating a chicken farm and you need to use paper trays when selling eggs. Then, at this time, you need an egg tray machine, that is, an egg tray molding machine. The mold needs to match the size of the egg. Therefore, the finished product can also be egg boxes, shoe trays, coffee trays, seed trays, wine trays, fruit trays, medical trays, hardware trays, etc. If you need it, you can contact us and we will get back to you as soon as possible!

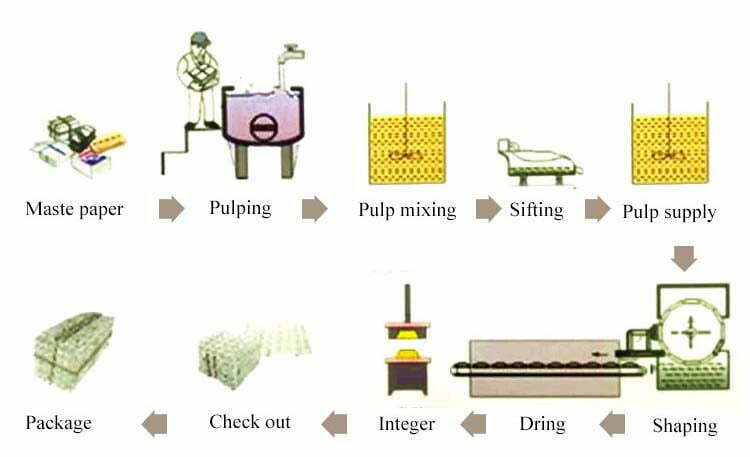

Process of Making Apple Tray

The operation is easy in the process of producing apple trays. . It can be roughly divided into pulping, molding, drying, hot pressing & packaging.

Pulping: in this process, waste paper is actually shredded into pulp by a high-pressure pulping machine. Prepare for the next step-molding. However, certain procedures need to be followed. Customers need to build three pools, one for water storage, one for crushed pulp, and one for proportionally mixed pulp.

Molding: this step is mainly to form the pulp, that is, through the forming machine, turn the pulp into the paper tray you want. A vacuum pump and air compressor are also required between pulping and molding. The vacuum pump sucks the pulp onto the forming mold, while the air compressor blows the formed mold onto the transfer mold.

Drying: because the newly formed mold contains certain moisture and is wet, it needs to be dried. There are three ways of drying: natural drying, brick kiln drying, and metal drying. You can choose the suitable drying method according to your own production scale.

Hotpress & packaging: Generally speaking, boxes need hot press shaping, because this will make the paper tray more beautiful and save space. Packaging is to collect and arrange the paper tray to make it neat and convenient to use.

Why Choose Shuliy Machinery?

In fact, there are many manufacturers of apple tray-making machines in the market, and there are many types. So why choose Shuliy Machinery as your supplier? The main points are as follows:

Considerate service: we provide pre-sales, in-sales, and after-sales service, and a 24-hour online manual service can answer your questions online at any time.

Quality assurance: our machines have relevant qualification certificates, such as CE, GMP, etc. And we have our own set of quality control systems, which can strictly control the quality of each component during production.

Customized services: you may have different needs according to your business. But we can customize the machine for you according to your requirements. Our technicians can provide professional suggestions to meet your needs.

Broad Prospects of Apple Tray Machine

With the continuous development of society, people pay more and more attention to the environment. This apple tray-making machine is an environment-friendly machine, which not only brings profits to businesses but also protects the environment. In addition, it will be very common in daily life. Apple tray can not only pack apples, but also save space, and is clean and tidy when storing. And the raw materials are cheap and easy to collect, which saves the cost. It is of great value as a business. Similarly, so is the egg tray machine. Looking forward to your calls!