Plastic recycling is a crucial process in the modern world, where sustainability and environmental consciousness are paramount. Two essential machines in the recycling industry are plastic granulator machines and plastic shredders. While both play a vital role in reducing plastic waste, they serve distinct purposes and offer different benefits. In this article, we will explore the differences between plastic granulators and shredders to better understand their applications and advantages.

Plastic Shredder: Reducing Large Plastics into Small Pieces

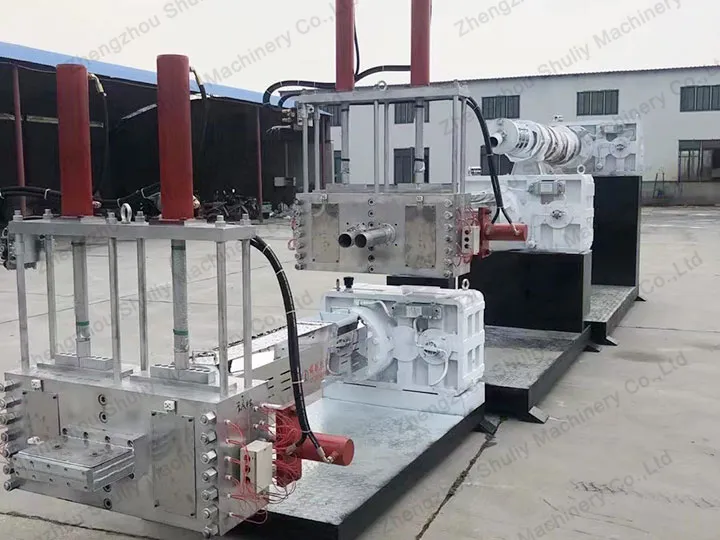

Plastic shredders are powerful machines designed to tackle large and bulky pieces of plastic waste. They are equipped with sharp blades or hammers that efficiently break down plastic items into smaller, more manageable chunks. Shredders are commonly used to process items like plastic bottles, containers, drums, and other voluminous plastic materials. The resulting shredded pieces can be further processed or used as a feedstock for other recycling processes.

Advantages of Plastic Shredders

Effective Size Reduction: Shredders excel at reducing large plastic items into smaller pieces, making them easier to handle and transport for further processing.

Versatility: Plastic shredders can handle various types of plastics, including rigid and thick materials, making them suitable for a wide range of application.

Speed: Shredders can process large quantities of plastic waste quickly, optimizing recycling efficiency.

Granulators: Transforming Small Plastic Scraps into Fine Granules

Plastic granulator machines, also known as plastic pelletizers, are designed to convert small plastic scraps, such as plastic film, sheets, and other post-industrial or post-consumer plastic waste into uniform plastic granules. These recycled plastic granules have a consistent size and shape, making them ideal for various manufacturing processes. Granulators utilize cutting blades or knives to chop the plastic scraps into smaller pieces before further processing them into granules.

Advantages of Plastic Granulator Machines

Precise Size Control: Granulators offer precise control over the size and shape of plastic granules, ensuring consistency in the final product.

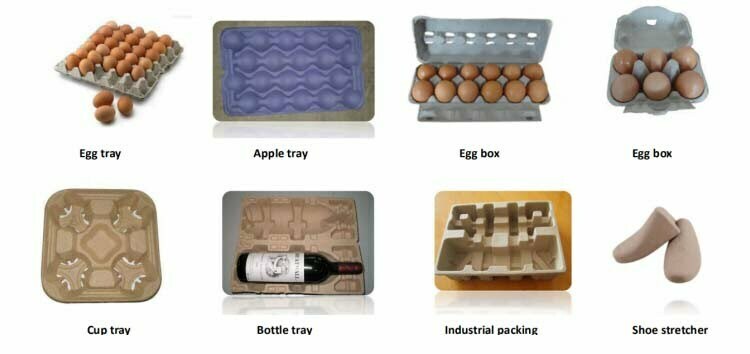

Versatility in Applications: Plastic granules produced by granulators are widely used in industries like packaging, automotive, construction, and more.

Enhanced Material Value: Plastic granules have a higher value in the market compared to shredded plastic, as they can be directly used as raw material in the manufacturing process.