In the global recycling trade, “clean” is a currency. Shredded metal fragments—whether copper, aluminum, or burnt iron—often carry surface contaminants that lead to heavy price deductions. The Shuliy industrial metal polishing machine is engineered to bridge this value gap. By implementing high-intensity dry friction, our equipment strips away rust, oil, and oxidation, transforming raw scrap into premium-grade materials ready for high-value resale.

Before & After: The Transformation of Shredded Metal

We don’t just process metal; we enhance its marketability. The impact of our industrial metal polishing machine is immediate:

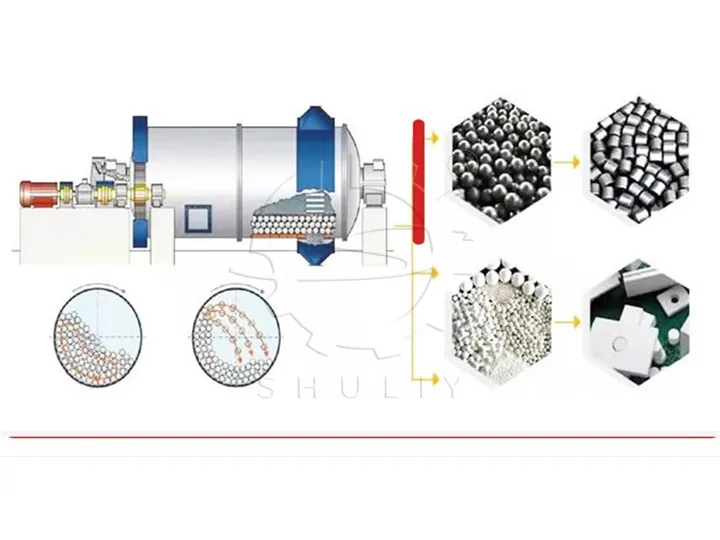

- Power Plant Burnt Iron: Heavy black oxidation is replaced by a bright, metallic luster.

- Copper & Aluminum Granules: Removes stubborn insulation residues and surface tarnish, reaching a “near-virgin” appearance.

- Small Hardware Fragments: Efficiently deburrs jagged edges, improving handling safety and material density.

System Integration: Where Does It Fit?

The Shuliy industrial metal polishing machine is designed as a modular component for high-output scrap metal recycling lines. It fits perfectly after your primary sorting phase:

- Shredding: Raw scrap is reduced to fragments (<400mm).

- Separation: Magnetic or air separators remove non-metallic debris.

- Refining (The Shuliy Step): The industrial metal polishing machine performs the final surface scrub and deburring.

- Final Grading: Cleaned fragments are bagged or sent directly to the furnace.

Technical Breakdown: The Physics of the Drum

Our dry grinding technology relies on a controlled high-energy environment within the drum:

- Integrated Turbulence System: The interior is lined with alloy turbulence-dissipating plates. This prevents “dead zones,” ensuring every fragment undergoes constant collision and friction.

- Abrasive Ore Interaction: By using specialized dry media, the machine absorbs oils and scours away rust without the environmental headache of wastewater treatment.

- Variable Speed Control: Adapt the tumbling intensity based on the fragility of your material—perfect for delicate aluminum chips or heavy steel shards.

Engineering Excellence: Built to Outlast

Shuliy machines are recognized for their “over-built” philosophy:

- Monolithic Casting Gear: The drive system utilizes a high-strength alloy aperture gear, cast as a single piece. This eliminates the weak points found in welded gears, ensuring flawless transmission under heavy loads.

- Extra-Thick Steel Armor: The drum body is constructed from reinforced, wear-resistant steel plates, designed to withstand the abrasive nature of sharp metal scrap.

- Simplified Maintenance: We believe in “Maintenance-Light” engineering. Lubrication points are centralized, and the internal liners are easily replaceable when worn.

Technical Specifications

| Specifications | Details |

| Core Equipment | Industrial Metal Polishing Machine |

| Process Type | Centrifugal Dry Grinding (Water-Free) |

| Material Range | Ferrous & Non-ferrous Shredded Metals |

| Infeed Size | Recommended < 400 mm |

| Surface Result | Roughness Improved by 1-2 Grades |

| Power Drive | Energy-Efficient Motor + Heavy-Duty Reducer |

Frequently Asked Questions

Q: How does this differ from a standard ball mill?

A: A ball mill is for pulverizing. Our industrial metal polishing machine is for surface refining. It cleans the surface without destroying the shape or size of your scrap fragments.

Q: Is water required for the cleaning process?

A: Not at all. This is a 100% dry process. No water, no sludge, and no drying costs.

Maximize Your Recycling Profits with Shuliy

Don’t let surface oxidation devalue your hard work. The Shuliy industrial metal polishing machine is the investment that pays for itself through higher material grades and lower disposal costs. Contact our engineering team today for a tailored quote.