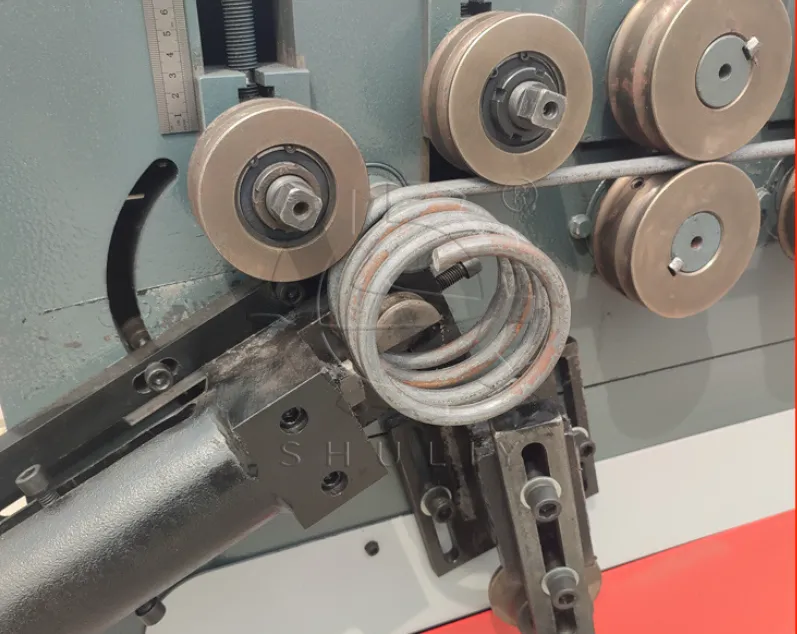

This spiral rebar bender tackles the demanding task of shaping straight steel bars into precise spiral or circular reinforcement forms. With accuracy to ±0.2 mm and bending speeds reaching 30 m/min, it transforms straight stock into high-quality coils at scale. Kick-off efficiency, slash labour time, minimise variation.

What is the Spiral Rebar Bender?

A spiral rebar bender is a specialised machine used in concrete reinforcement works. It bends rebars into circular or helical shapes — essential for applications such as pile cages, tunnel hoops, high-speed rail anchors, or prefabricated rings. Equipped with CNC input and hydraulic drive, the machine automates feed-bend-cut operations and handles a range of diameters from small hoops to large spirals.

Key Benefits of Our Rebar Circle Making Machine

For businesses looking to invest in a reliable and powerful steel bar hoop bender, the Shuliy model stands out. Our Fully Automatic CNC Five-Head Slab Bar Bending Machine is engineered for high-volume, high-precision work, making it the ideal choice for demanding projects.

- Automated CNC control: set hoop diameter, coil pitch, and batch quantity once; let it run.

- High precision output: consistent shape and size across large runs; reduces scrap.

- Rapid production rate: suitable for high-volume fabrication plants or demanding job sites.

- Robust hydraulic system: strong bending force, stable performance under heavy load.

- Wide material compatibility: supports multiple bar diameters, various reinforcement grades.

How the Rebar Ring Bender Works?

Once parameters are programmed, the system’s PLC activates the motor and hydraulic pump. The steel bar is straightened, fed into the rounding assembly, bent into the preset spiral or circle, and cut automatically. One smooth cycle: feed → bend → cut. This continuous loop ensures minimal manual intervention and high output consistency.

Technical Specifications at a Glance

| Model | Steel Bar Diameter(mm) | Spiral/ Circle Diameter(mm) | Motor Power(kW) | Speed(m/min) | Accuracy(mm) | Weight(kg) |

| SL-3 | 3-6 | 50-1000 | 4 | 16-25 | ±0.2 | 480 |

| SL-6 | 6-10 | 50-800 | 5.5 | 16-25 | ±0.2 | 560 |

| SL-8 | 8-12 | 50-1500 | 7 | 16-25 | ±0.2 | 640 |

| SL-10 | 10-14 | 50-1800 | 7 | 16-25 | ±0.2 | 690 |

| SL-16 | 16-20 | 50-2200 | 11 | 16-30 | ±0.2 | 1150 |

| SL-25 | 22-25 | 50-3000 | 15 | 16-30 | ±0.2 | 1350 |

Note: Custom voltage or diameter ranges can be provided.

Applications for the Spiral Rebar Bender

- High-speed railway & metro projects – forming spiral cages and anchors.

- Bridge and tunnel reinforcement – producing large circular hoops with accuracy.

- Foundations for buildings, wind or solar bases – spiral reinforcement for piles.

- Pre-cast concrete component fabrication – large-batch ring or coil manufacture.

These applications rely on machines that deliver speed, repeatability, and durability.

Why Choose Shuliy Machinery for a Spiral Rebar Bender

Shuliy Machinery brings over two decades of experience in steel bar processing equipment. We focus on building machines that are reliable, serviceable, and designed for production environments.

- Machine designs rooted in field use and real site requirements.

- Quality components and strict QC ensure long service life.

- Custom configurations available to match regional power and job-site specs.

- Clear support channels: installation help, parts supply, remote guidance.

In short: you’re investing in a machine that works — not just looks good on paper.

Conclusion

If your operations require consistent, high-volume production of spiral or circular steel reinforcement, the Shuliy spiral rebar bender is engineered for that. With accuracy, speed, and automation built in, it delivers the output, quality, and reliability modern projects demand. Connect with our team to explore configurations, pricing, and next-step demonstrations.