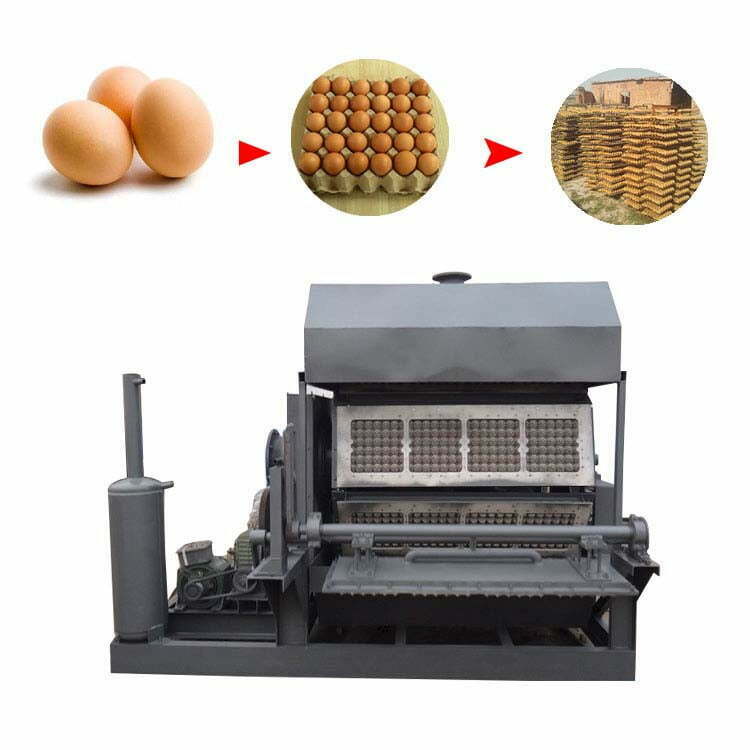

Egg tray molding machine is the main part of the molding process during making the egg tray. The egg tray molding system is the core part of the egg tray production line, and the pulp molding machine is the top priority. If the whole egg tray production line is considered the human, the pulp molding machine is the brain of humans. Hence, the importance is self-explanatory. Besides, the equipment is usually a rotary pulp molding machine. According to the different mould, we can make different trays, such as egg trays, apple trays, egg cartons, medical trays, etc. What’s more important, this machine is an environmentally friendly machine, beneficial to our living conditions. Contact us to learn more details!

Working Plant of Egg Tray Molding Machine

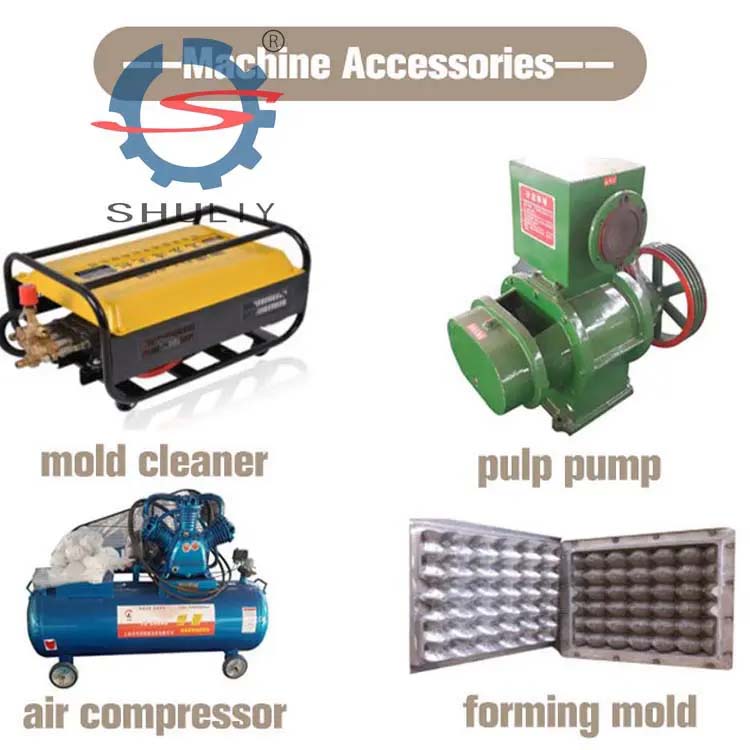

Egg tray molding machine is a high efficiency, low energy consumption, ultra-high stability equipment. Generally, the moulding machine, vacuum system, air compressor+high pressure pipe, mold cleaning machine compose the forming system. We’ll detail as follows.

Egg Tray Moulding Machine

It is made of forming molds and transfer molds. The number of forming molds will influence the capacity of the machine. It also has other components. Listed as below: electromagnetic valve, two-position five-way, butterfly valve, control cabinet, globe valve, rubber hose, proximity switch. These are common collocations. However, the allocation will differ based on the production capacity.

Vacuum System

The vacuum system consists of the vacuum pump and the vacuum piping. Its function is to attach the pulp to the forming dies and remove the most water from the pulp. The same theory is applied to the vacuum system. It’s that the configuration changes along with the production capacity.

Air Compressor

The air compressor normally works for the molding machine. In the molding process, it mainly separates the formed mould from the forming dies, making formed mould come to transfer mould.

Mold Cleaning Machine

As the name suggests, it’s used for cleaning the mold. Because the pulp is the mixture of waste paper and water, when finishing mold, some dirt leaves. At this time, a mold cleaning machine is needed to make it clean and tidy so that it can be used again.

All in all, the vacuum system, air compressor, molding cleaning machine all serve to mold machine. When you’re going to buy one molding machine, these three are necessary.

Various Egg Tray Molding Machine from Shuliy Machinery

From the perspective of yield, several types are 1000 pcs/h, 1500-2000 pcs/h, 3000 pcs/h, 5000 pcs/h, 6000 pcs/h, 8000 pcs/h. As the key parts of molding equipment, the shape, appearance, and size of the mold should be considered when designing the mold, even if the mold is often used, their texture should be durable. There are usually two kinds of molds, namely forming molds and transfer molds. We will provide you with the most satisfactory solutions according to the different needs and help them build a complete egg tray production line. Our molding machine can not only produce egg trays, but also fruit trays, tray shoes, industrial trays, medical trays, and so on. Want to know more? Don’t hesitate to call us!

Advantages of Paper Pulp Moulding Machines

- The main machine adopts Taiwan gear divider technology to achieve equipment operation accuracy with zero error.

- The main machine base is made of thickened16# channel steel, and the transmission shaft is precision machined with 45# round steel.

- The motor of the whole machine adopts domestic well-known brands.

- The positioning slide of the main engine is welded with a 45# steel plate after heat treatment.

- Domestic well-known brands are selected for vacuum pumps and air compressors.

- High and fast return on investment for the investors.

- It’s equipped with a user-friendly control panel with a low-maintenance service system.

- We support customization services.

End Products of Pulp Molding Production Line

The end products of the pulp molding machine are not only egg tray, but also egg boxes, fruit tray, wine tray, medical tray, shoe tray, seedling tray, industrial tray, electrics tray, cup tray, etc. In fact, the raw materials for molding machines are with wide sources. For instance, waste paper, waste boxes, waste newspapers, waste magazines, etc. It’s cheap and very easy to get. For the investors, it’s low cost. Obviously, the pulp molding production line is great to invest in. In addition, the pulp molding machine makes paper molded trays, which are biodegradable. With the ban on plastic in many countries, paper trays are getting popular. More than that, the pulp molding production line is pollution-free.

Leave Your Information

Being a reliable paper molding machine manufacturer and supplier, we provide the molding machine of high quality, reasonable price, long service life. The pulp molding machine price differs along with the production capacity and collocation. We equip molding machine with well-known brands. To some extent, high allocation brings a higher price. But all deserve this. If you’re ready for the paper tray making machine, tell us what production capacity you want. We offer the perfect solutions with thoughtful services. Of course, after-sales service is included. Trust us, this machine is great ROI (return on investment). Do you want to know how to choose the best egg tray molding machine, please click this egg tray making machine buying guide. If you have any doubts, please connect us immediately, we’ll reply to you very soon.