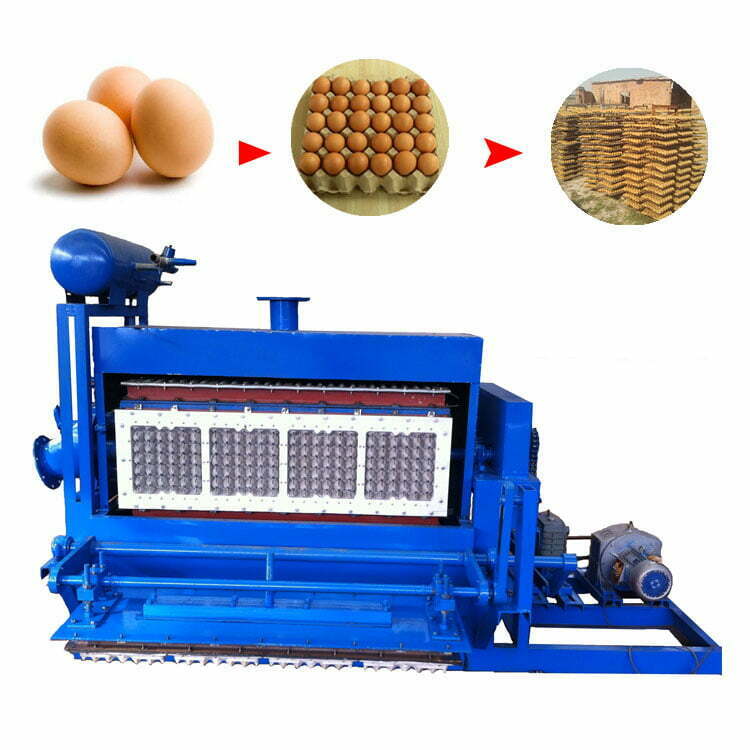

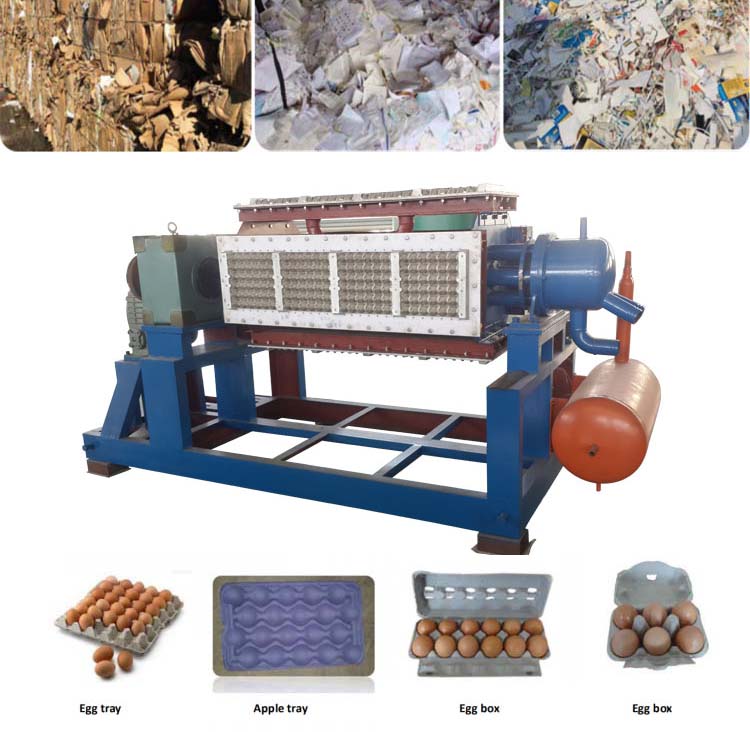

Egg tray making machine is an environmentally friendly machine, which can turn waste into treasure. That’s because of its raw materials. The raw materials are mainly from various pulp boards such as waste paperboard, waste paper box paper, waste white paper, reed pulp, straw pulp, slurry, bamboo pulp and wood pulp, paper mill tail pulp waste, etc. The raw materials are particularly easy to collect, and a large number of raw materials are produced every day. With the development of society, regions and countries all over the world pay more attention to the environment. It’s a tendency of social progress. That’s why the egg tray machine is well-received. Hence, do you want this paper tray making machine? Contact us now!

Outstanding Paper Egg Tray Maker for Sale

In Zhengzhou Shuliy Machinery Co., Ltd, we generally divide the egg tray machine for sale according to the drying methods. Normally here two types are fully automatic and semi-automatic. Fully automatic refers to the drying method of mental egg tray drying line with several layers. The semi-automatic is a reference to the drying method of natural drying and brick egg tray drying line. However, the brick egg tray drying line should be built by clients themselves. In accordance with the productivity, we classify it into 1000 pcs/h, 1500-2000 pcs/h, 3000 pcs/h, 4000 pcs/h, 5000 pcs/h, 6000-7000 pcs/h. Generally speaking, we utilize two numbers to describe. For example, use 3*1 to express the productivity 1000 pcs/h (3 represents three pieces once, 1 represents only one forming mould). Please contact us for more details!

Various Applications of Paper Tray Making Machine

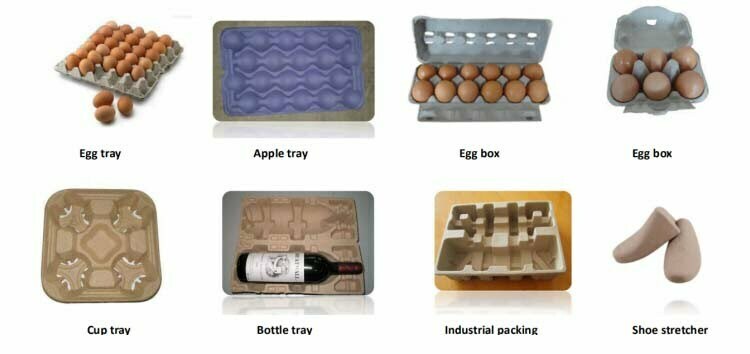

We recycle the waste materials so as to produce the items used in life. The Paper tray making machine is such a machine. The finished products of the egg tray manufacturing machine are egg trays. Besides, the end products also can be egg boxes, egg cartons, quail egg trays, apple trays, fruit trays, shoe trays, electrics trays, coffee cup trays, paper model, seedling trays, wine tray, medical tray, etc. What to be aware of is that it’s a paper tray making machine, not a plastic tray making machine. In addition, there are many raw materials that can be used for making egg holders. The raw materials include waste paper, waste newspaper, waste magazine, corrugated paper, and others. This is the charm of environmentally friendly machines. The egg tray making machine is in a position to fulfill this obligation. Do you want to be our cooperator? Get in touch with us very soon!

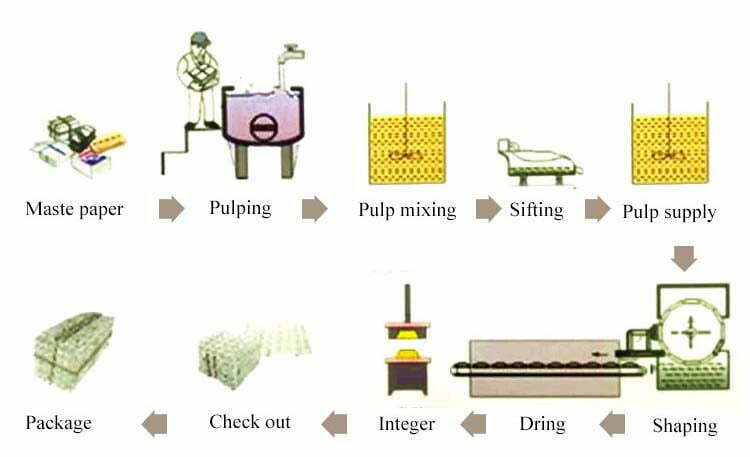

What’s the Technological Process of Egg Tray Machine?

The egg tray production line is described as: waste paper→pulping→pulping mixing→sifting→pulp supply→shaping→drying→integer→check out→package. The overall process can be summarized into the following steps: respectively pulping system, forming system, drying system, and egg tray reshaping & packing system.

Pulping System

Pulping is the first step to producing egg trays. In this step, a egg tray pulping machine is necessary. It consists of pupler and butterfly valve. Of course, other collocations are pulp pump, pulp pond beater, wastewater pump, pulp conveying pipe. But it has slight change on the basis of the different productivity. This process is to put the waste paper into the pulper and add water in order to smash and get the pulp.

In addition, three pools are requested for pulp. One is holding the original pulp, another one is for water, and the remaining one is for the pulp of a certain proportion. So, don’t forget to mix the pulp with water a certain proportion before continuing the next step.

Forming System

Molding machine, vacuum system, air compressor & high pressure pipe, and molding cleaning machines are commonly used. Through pulp conveying pipe, the pulp comes to the supply tank of the molding machine. And then with the assist of the vacuum system, the pulp is absorbed into the forming mould. Meanwhile, the white water is sucked and transported back into the pool. Next, the formed mould is blow out to the transfer mould by the air compressor. Finally, the mould is sent out by the transfer mould. What should be focused on is that one egg tray making machine has only one moulding machine.

Drying System

Its function is to squeeze excess water into wet egg trays. There are three types of drying methods available for your choice. Different drying methods have a different allocation.

- Natural drying in the sun is suitable for small-scale egg tray production(suitable for 2000 pieces or less). This method needs the help of laborers.

- Brick egg tray dryer is matched with 2500 pieces and above; it’s medium-scale production. Fewer labors are needed in spite of the brick kiln built at their own cost.

- Metal egg tray drying system is used for customers who limited land space. It usually has a single layer and multiple layers. Almost no labor as well as full automation.

Egg Tray Reshaping & Packing System

Reshaping needs a hot-pressing machine. The aim is to save space and cost. Also, it makes the appearance smooth. Universally the egg tray doesn’t need a reshaping process unless it’s the egg carton. Finally, we apply an egg tray packing machine to pack the egg tray, making it easy to deliver.

And you can also choose the automatic collector, automatically collecting the egg tray after drying.

We can provide three pools drawings and produce the customized products in accordance with your actual demands.

How to Find A Good Reputable Paper Egg Tray Making Machine Manufacturer & Supplier?

We Zhengzhou Shuliy Machinery Co., Ltd is a company integrating research & study, and production. we have advantages as follows. Firstly, our company has accumulated almost thirty-year experience in this area. Thereby, we’re the rich-experienced company to supply the egg tray making machine. Secondly, we cooperate with famous brands. Due to components of famous brands, our machines have superior quality and stable performance. Thirdly, we offer excellent services to our customers. Whatever time it is, as long as customers have needs, we will give solutions and quick responses. Moreover, you can get these paper pulp egg tray making machines if you’re running a chicken farm. The machine can help you promote your interests and benefit back to your business.

What’s Egg Tray Machine Price?

When you go to purchase the egg tray making machine, it’s imperative for you to be clear with your order plans. Because now many manufacturers and suppliers have this machine, you should compare and then get the most beneficial one. Our egg tray machines are equipped with well-known components, so they have competitiveness. But at the same time, its price changes along with the collocation. What’s more, you have to consider your budget and paper tray machine cost. Your budget determines how big the machine you will buy. And among all egg tray makers, the manual egg tray manufacturing machine price is the cheapest. Thus, if you decide to buy such environmentally friendly machines, you should consider your order plans, budget, and machine cost.

Contact Us to Facilitate Your Business

Being a responsible enterprise, we closely follow the pace of social development. So in our company, automatic egg tray machine is naturally to reduce the burden of the earth, promote the sustainable progress. If you have a lot of recycled paper, that’s why we recommend this machine to you. The first advantage of the machine is environmentally friendly. it’s replacing the plastic tray. The second one is the wide sources of raw materials and low cost. The raw materials are easy to collect and cheap. Therefore, come to contact us for doing something in order to protect our environment. Please call us for more details and we’ll reply very soon!