Egg carton making machine is designed and manufactured for producing various pulp egg cartons for long-distance transportation of eggs. It can recycle all kinds of waste paper boxes, waste newspapers, and waste books and make these materials into egg cartons of various styles. With the increasing awareness of environmental protection, people are more inclined to choose relatively environmentally friendly machines. And the main raw material of the egg carton making machine is waste paper, which is in line with people’s environmental protection concept. Besides, the egg carton machine has a wide range of uses. Except for making all kinds of egg cartons, it can also make various apple trays, wine trays, cup trays, medical trays, coffee trays, seedling trays.

Furthermore, our machine also has stable performance and high working efficiency, which can bring you many benefits. Welcome to contact us for more information.

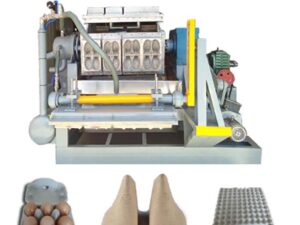

Different Egg Carton Making Machine for Sale

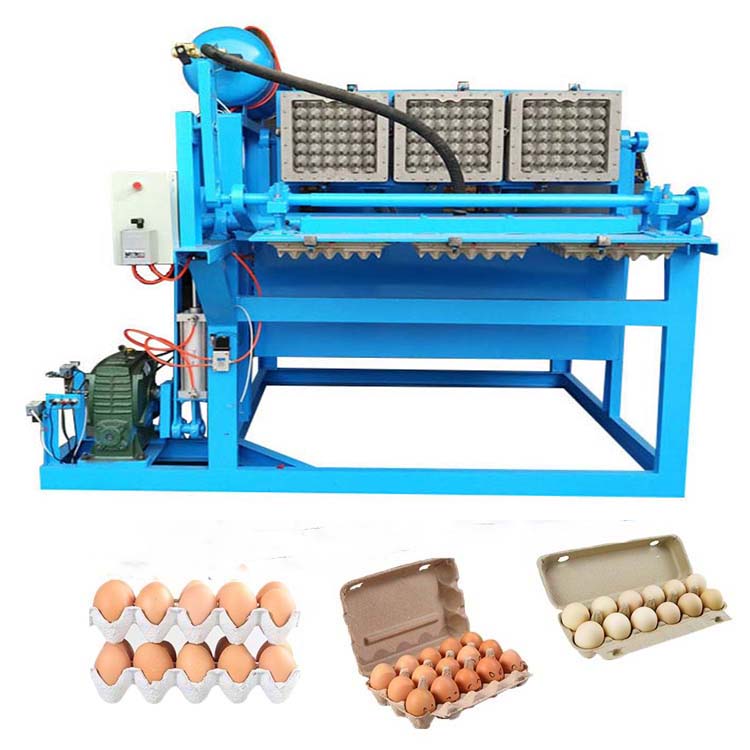

As a professional egg crate machine supplier, there are different types of egg crate making machines available. For example, according to the output of the machine, we have large egg crate machines and small egg crate machines to choose from. The small machine is suitable for small businesses or homes. While the large machine is suitable for large-scale production and has the advantages of high efficiency and large output. In addition, according to the degree of automation, we have semi-automatic egg crate machines and fully automatic egg crate machines. Their main part is both fully automatic, but the drying system is different. The fully automatic system uses metal drying, which can automatically complete the drying process, thereby saving a lot of time and labor costs. The semi-automatic drying system includes brick kiln drying and trolley drying. Its advantages are low cost. You can choose according to your specific needs.

Main Components of Egg Crate Making Machine

A complete egg box making machine mainly includes pulping parts, forming parts, vacuum parts, and hot pressing parts.

Pulping Parts: This part contains a hydraulic pulper, conveying pipe, pulp pond beater, etc. Through this process, various waste papers can be made into pulp.

Forming Parts: This part is mainly made of a molding machine and forming mold, which can turn paper pulp into different kinds of egg boxes according to specific needs.

Vacuum Parts: This part is constructed of a vacuum pump, vacuum subnormal pressure container, etc. The vacuum system can suck the pulp onto the mould of the forming machine and absorb the excess water into the water vapor separation tank.

Hot pressing and packing parts:

In order to save packing space and make the surface of the egg carton smooth, the client can choose to hot press the egg carton. This way can facilitate the transportation of egg cartons.

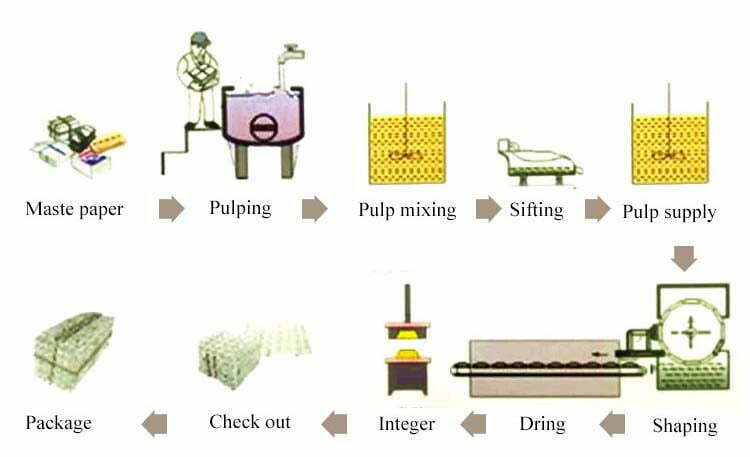

Working Process of This Machine

The egg box manufacturing process mainly includes four parts: pulping, forming, drying, and hot pressing.

- Pulping

Put raw materials such as various waste paper, waste books, and waste boxes into the hydraulic pulper. Then add the appropriate amount of water and stir for a long time. In this way, a certain consistency of pulp can be obtained. Then the even paper slurry is stored in the pulp supply pond for standby.

- Forming

A pulp molding machine is applied to do this job. It can absorb the prepared pulp onto the forming mold, thereby making the pulp into a complete egg carton.

- Drying

There are four drying methods. You can choose natural drying, brick drying, trolley drying, and metal drying.

- Natural drying: The egg carton is directly dried by the sun and natural wind.

- Brick drying: When building brick kiln tunnels, we can choose natural gas, diesel, coal, and other fuels.

(3) Trolley drying: Push the formed egg trays to one place with a trolley for centralized drying.

(4) Metal drying: it is a fully automatic drying method.

- Hot pressing

Use a hot press shaping machine to shape the dried egg carton, which can make the surface of the egg carton cleaner and save space. Then pack the shaped egg trays for use.

Various Advantages of Egg Box Machine

- The main components of egg carton making machines are all well-known brands, which are highly efficient, energy-saving, and durable.

- The drying systems are diverse, and customers can choose the most suitable drying line according to the specific situation. In addition, the drying system fuel can use various fuels such as natural gas, coal, petroleum, etc., which can be selected according to the customer’s local conditions.

- This egg tray machine production line is energy-saving, environmentally friendly, practical, and beautiful. Throughout the production process, there is no wastewater discharge.

- The raw materials of egg trays are newspapers, magazines, books, cartons, etc. Therefore, the raw materials are abundant and the price is low and thus can reduce costs for customers and improve efficiency.

Maintenance of Egg Box Making Machine

- During the use of the equipment, always check whether the gas supply system is normal and whether the power supply line is damaged or heated.

- When abnormal impact or noise occurs during the operation of the equipment, you should shut it down immediately for inspection to find out the cause and eliminate it.

- Pneumatic parts must be lubricated, and oil should be added to the oil cup on the triple piece regularly.

- For long-term shutdowns, turn off the power supply to the equipment, and regularly refuel and inspect the moving parts of the equipment to ensure that the equipment operates normally during use.

How to Choose the Right Egg Carton Making Machine?

- Figure out the purpose of the device. If you plan to expand your business, you may need an egg box making machine that can also produce other types of paper trays.

- Cost. Many manufacturers have their own websites. They use these websites to promote their machines. You can visit different websites and check the fees. Compare prices and advantages of different manufacturers.

- The quality of the machine. After understanding the manufacturer’s costs, the next step is to determine the quality of their machines. The prices of some manufacturers may be particularly low, but the quality of their machines is generally not high. You can compare more manufacturers and choose the most cost-effective one.

- Maker’s experience. Which manufacturer should you trust? You’d better choose an experienced egg tray maker manufacturer. Because they may have better machines and services.

Why Choose Us as Your Manufacturer?

When you buy a machine, you need to pay attention to some important information. This information will help you buy better quality egg carton making machines and trusted manufacturers. Here are the reasons why our customers choose us.

Rich experience. Zhengzhou Shuliy Machinery Co., Ltd has a history of more than 20 years. During this time, we have been committed to producing high-quality egg carton machines. Therefore, we have accumulated a wealth of experience and technology.

High-quality machine. Our machines have passed strict quality inspections and fully comply with international standards. Our machines are not only high in quality but also stable in performance. You can buy with confidence.

Vast market. Our egg tray machines are favored by customers because of their high-quality quality and favorable prices. At present, our products are exported to more than 50 countries and regions such as the United States, Canada, South Korea, and Japan.

Perfect Service. We provide high-quality pre-sales, in-sales, and after-sales services. No matter what problems you encounter, you can always contact us. We have professional staff to answer your questions. Welcome to contact us as soon as possible.