Dans l'industrie du recyclage des plastiques, la mousse plastique (également connue sous le nom de polystyrène, EPS ou Styrofoam) représente un défi unique. Légère, volumineuse et notoirement difficile à décomposer, ce matériau peut être un cauchemar pour les recycleurs. L'étape de concassage en particulier a longtemps été considérée comme un goulot d'étranglement dans le recyclage du styrofoam, entraînant souvent des coûts de main-d'œuvre élevés, une faible efficacité de production et des blocages d'équipement.

Mais qu'est-ce qui rend le broyage du polystyrène si problématique ?

Pourquoi le polystyrène est-il difficile à broyer ? Liste des luttes courantes

Le déchiquetage du polystyrène consiste à pulvériser de gros blocs de mousse en petits morceaux uniformes qui peuvent être granulés et recyclés. Les méthodes de broyage traditionnelles s'appuient souvent sur des déchiqueteuses à usage général ou sur une manipulation manuelle, ce qui est inefficace et chronophage.

Les raisons pour lesquelles les mousses plastiques sont difficiles à broyer sont :

- La densité de la mousse est faible et le volume est important. Le broyeur à polystyrène traditionnel ne peut pas traiter le matériau, ce qui entraîne un temps d'inactivité et un gaspillage sérieux de la capacité de production.

- La forte élasticité et l'amortissement de la mousse absorbent l'impact des outils, ce qui fait chuter l'efficacité du broyage.

- Lors du processus de broyage, la mousse EPS génère facilement de l'électricité statique, ce qui fait que la mousse cassée adhère au mur du broyeur de polystyrène et entraîne un encrassement supplémentaire. Cette situation est particulièrement évidente dans des environnements avec une humidité inférieure à 40 %.

- De plus, la mousse est sensible à la chaleur. Pendant le processus de déchiquetage, elle chauffe en raison de la friction et s'assouplit et fond à des températures de 60 °C ou plus. Cela crée une "couche de gel" qui enveloppe la lame et peut entraîner un arrêt complet de l'équipement dans des cas graves.

Et les problèmes pratiques courants pour les broyeurs de polystyrène incluent également :

- Il y a des difficultés avec l'alimentation continue, ce qui entraîne une faible efficacité et une production bien en dessous de la valeur théorique (environ 30 % seulement).

- Les outils s'usent rapidement et se cassent facilement lorsque le matériau fondu y adhère, nécessitant un remplacement fréquent et augmentant les coûts d'exploitation.

- Une forte concentration de poussière augmente le risque potentiel d'explosion de poussière.

- Le produit fini a un taux d'impuretés élevé. S'il n'y a pas de pré-tri, les résidus de ruban adhésif et d'étiquettes affecteront gravement la qualité des matériaux recyclés.

En résumé, le concassage de mousse est difficile et peut facilement endommager la machine, provoquer des blocages et entraîner une faible efficacité et des coûts élevés. Il doit s'appuyer sur un équipement professionnel de concassage de mousse et des systèmes de soutien pour résoudre ces problèmes.

Comment résoudre les problèmes de déchiquetage du polystyrène ci-dessus ?

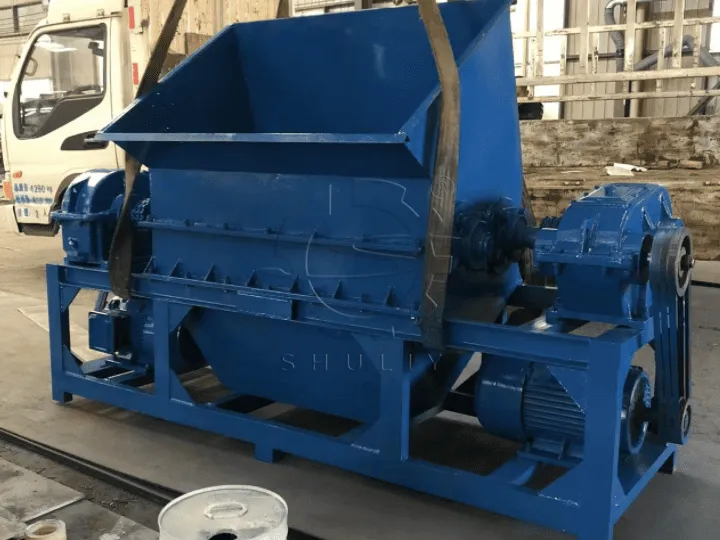

Reconnaissant ces points faibles de l'industrie, Shuliy Machinery a développé une gamme complète de broyeurs de polystyrène, disponibles en configurations verticales et horizontales. Conçues spécifiquement pour le PSE et les matériaux en mousse similaires, les broyeurs PSE de Shuliy sont conçues pour résoudre les problèmes réels auxquels sont confrontés les recycleurs.

Caractéristiques clés des broyeurs de polystyrène Shuliy :

- Système d'alimentation anti-dérapant – Plus de rebond de matériau

Notre broyeur utilise un arbre à plusieurs dents et un angle de lame optimisé pour saisir efficacement la mousse souple, éliminant le glissement et garantissant un rendement réel élevé. - Broyage résistant à l'élasticité – Efficace contre la mousse élastique

Les lames sont spécialement positionnées pour contrer l'effet de rebond de la mousse, rendant le broyage plus rapide et plus fluide même avec des matériaux souples et flexibles. - Conception anti-bouchage – Fonctionne même dans des conditions sèches

Les revêtements antistatiques et les voies d'extraction de la poussière empêchent les particules de mousse de coller à la chambre et aux lames, même dans des environnements à faible humidité (<40%). - Broyage à basse température – Évite la fusion ou le blocage des lames

Une dissipation thermique intelligente et un flux d'air structurel empêchent l'accumulation thermique, évitant le ramollissement de l'EPS ou l'encapsulation des lames avec des résidus collants. - Support d'alimentation continue – Fonctionnement stable et ininterrompu

Compatible avec les alimentateurs automatiques ou les convoyeurs à mousse pour un traitement fluide et ininterrompu - idéal pour les usines à grande échelle. - Lames Résistantes à l'Usure – Durée de Vie 3× Plus Longue

Les lames en acier allié à haute dureté résistent à l'abrasion de la mousse et à la friction à grande vitesse, réduisant la maintenance et la fréquence de remplacement des lames. - Système de Contrôle de la Poussière – Opération Plus Sûre et Plus Propre

Collecteur de poussière cyclone ou système de filtration à dépression optionnel réduisant la concentration de poussière de PS dans l'air et minimisant le risque d'explosion. - Fonction de pré-tri optionnelle - Sortie de pureté supérieure

Fonctionne avec des systèmes de pré-tri pour éliminer les rubans, étiquettes ou autres impuretés, améliorant la qualité et la valeur de revente des granulés recyclés.

Que vous ayez besoin d'un broyeur de polystyrène compact à vendre pour votre centre de recyclage local ou d'un broyeur EPS à grande échelle pour un usage industriel, Shuliy propose des broyeurs de polystyrène multi-modèles pour répondre à vos besoins.

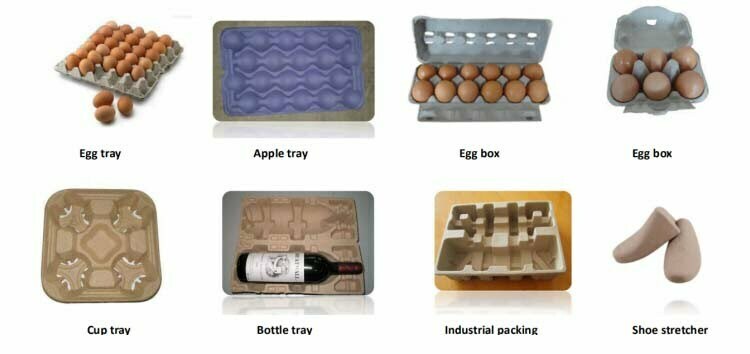

Large application du broyeur EPS Shuliy

Les broyeurs en polystyrène de Shuliy sont très polyvalents et capables de traiter une large gamme de matériaux en mousse, y compris les panneaux d'isolation, les boîtes en mousse d'emballage express, la mousse EPE, les contenants alimentaires en mousse, et plus encore. Que vous dirigiez un petit atelier ou une usine de recyclage de polystyrène à grande échelle, nous pouvons recommander — ou personnaliser — la solution de broyage et de recyclage la plus adaptée à vos besoins.

Nos déchiqueteuses de polystyrène sont bien accueillies dans de nombreux pays et régions grâce à leurs performances fiables, leurs prix compétitifs et leur excellent support après-vente.

Si vous rencontrez toujours des difficultés avec le broyage de matériaux en mousse, ne vous inquiétez pas – envoyez-nous vos matériaux et vos exigences, et laissez Shuliy vous aider à résoudre le problème efficacement !