A medida que la industria automotriz se desarrolla, el número de neumáticos desechados aumenta, haciendo que el reciclaje de neumáticos sea un proyecto popular. Shuliy Machinery ha desarrollado tres tipos de líneas de producción de polvo de caucho totalmente automatizadas que pueden convertir de manera eficiente los neumáticos desechados en polvo de caucho, ayudando a los recicladores de neumáticos de todo el mundo a operar negocios rentables y respetuosos con el medio ambiente.

Aplicación de líneas automáticas de reciclaje de neumáticos

Estas líneas son adecuadas para procesar neumáticos de hasta 1200 mm de diámetro mediante el desmantelamiento, triturado y molienda. Este proceso produce los alambres de acero, polvos de caucho y fibras de nailon dentro de los neumáticos de desecho, que pueden ser clasificados y reciclados.

Esta línea de reciclaje de neumáticos totalmente automática, altamente eficiente y que ahorra mano de obra, se recomienda para empresas medianas y grandes.

Ventajas principales de las líneas de producción de polvo de goma totalmente automáticas

- Alta eficiencia: hasta 18 toneladas de polvo de caucho por día.

- Productos finales de alta calidad: La pureza del polvo de goma terminado es de al menos el 99%, proporcionando un alto valor añadido.

- Flexibilidad: Una variedad de programas para elegir, con finura ajustable del polvo de goma.

- Protección del medio ambiente: Bajo consumo de energía y cumplimiento de las normas CE de la Unión Europea y de las normas de emisión de polvo.

Tres tipos de líneas de producción de polvo de caucho

Solución de reciclaje de neumáticos 1:

Incluye equipo: máquina desalambradora de neumáticos, máquina cortadora de neumáticos, trituradora de neumáticos, sistema de molienda y cribado de neumáticos

Proceso de trabajo detallado:

- La máquina despojada de neumáticos extrae los aros de acero de los aros internos de los neumáticos utilizando un potente dispositivo de tracción hidráulica.

- La cortadora de neumáticos corta los neumáticos en dos o tres piezas, que son fáciles de poner en la trituradora para su procesamiento.

- La trituradora de neumáticos aplasta los neumáticos en piezas pequeñas y uniformes, mejorando la eficiencia del posterior triturado.

- La línea de fabricación de polvo de caucho produce polvo de caucho de alta calidad con una finura ajustable de 10 a 40 mallas a través de procesos como el molino de rodillos dobles, la clasificación por pantalla vibrante y la separación magnética.

Planta de reciclaje de neumáticos usados 2:

Incluye instalación: máquina desalambradora y cortadora de neumáticos, separador de alambre de acero de neumáticos, trituradora de neumáticos de caucho, línea de trituración de neumáticos

Proceso de trabajo completo:

- La máquina de extracción y corte de bead de neumático elimina el bead del neumático que contiene los alambres de acero y corta el neumático, que luego entra en la máquina de triturado de neumáticos a través de una cinta transportadora automática.

- El separador de alambre de acero de neumáticos separa las porciones de goma y alambre de acero del talón del neumático, siendo la porción de goma también apta para ser procesada en la trituradora.

- La potente trituradora y los sistemas de molienda y clasificación luego aplastan, muelen y eliminan impurezas de la goma.

- Salida: Polvo de goma altamente puro, cuya finura se puede ajustar utilizando la malla.

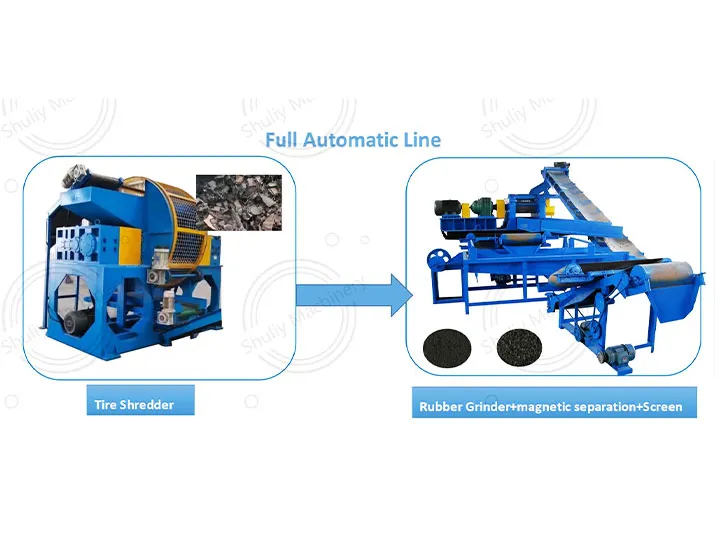

Línea de producción de polvo de caucho 3:

Incluye máquinas:

Trituradora de goma industrial, molino de goma para neumáticos y separador magnético

Flujo de trabajo:

A diferencia de las dos soluciones anteriores, esta solución de reciclaje de neumáticos no requiere preprocesamiento. El neumático entero se puede introducir directamente en una trituradora de neumáticos de alta potencia, seguida de un molido profundo y un tamizado.

Casos de éxito sobre líneas de producción de neumáticos de goma

Hemos exportado anteriormente líneas de reciclaje de neumáticos totalmente automatizadas a Canadá, Qatar, Sudáfrica, India y otros países, ayudando a establecer fábricas de reciclaje de neumáticos y mejorar la eficiencia en todo el mundo. Por ejemplo, después de introducir la línea de producción automática de polvo de goma Shuliy 560# en una fábrica canadiense, su producción diaria aumentó a 5 toneladas, mejorando enormemente la eficiencia y la rentabilidad.

Equipo automático de reciclaje de neumáticos en venta

Como proveedor líder de equipos de reciclaje de neumáticos, podemos ofrecer un servicio integral, desde el diseño y la instalación hasta el soporte postventa. Si está interesado, ¡no dude en ponerse en contacto con nosotros!