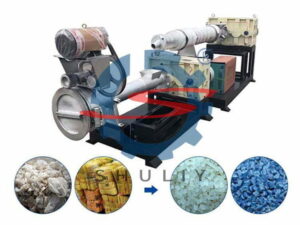

EPS foam densifier também é conhecido como a máquina de briquetagem de EPS e compactador de styrofoam, usada para comprimir espumas, como plásticos de espuma EPS ou EPE. O princípio de funcionamento é comprimir a espuma EPS em blocos densos por meio de um mecanismo de compressão por parafuso. De acordo com as características das matérias-primas, a relação de compressão pode chegar até 40 vezes, para reduzir o volume da espuma. Os blocos de espuma comprimida são convenientes para o transporte em longas distâncias e armazenamento, o que economiza custo de transporte e espaço de armazenamento. Além do compactador de styrofoam, também fornecemos máquinas de fusão a quente de espuma para reduzir o volume de EPS ou EPE plástico de espuma de desperdício.

Destaca o densificador de espuma EPS

- Depois de comprimir o volume de espuma EPS 30-40 vezes menor do que antes, a densidade da espuma é grande e os blocos de espuma são facilmente cortados, armazenados e reciclados. Economize espaço de armazenamento e custos de transporte e armazenamento

- O compactador de isopor é equipado com mecanismo de pré-trituração para garantir eficiência de trabalho e manter baixo consumo de energia. Diferentes tamanhos de portas de alimentação podem ser selecionados para tratamento de prensagem a frio.

- Modelos grandes podem operar de forma síncrona com a correia transportadora para melhorar a eficiência da produção.

Como funciona o compactador EPS?

O compactador a frio de espuma EPS comprime a espuma plástica de acordo com o princípio da rotação do parafuso e da compressa fria. Em operação, o operador só precisa jogar a espuma residual na tremonha, e o densificador de espuma EPS possui um mecanismo de trituração para esmagar o bloco de espuma. Em seguida, o mecanismo de parafuso comprime o pequeno isopor/espuma de poliestireno em um bloco de compressão cúbico. Existe um dispositivo regulador de pressão na extremidade frontal da seção de compressão para ajustar a taxa de compressão. Depois que o material é processado pelo mecanismo de parafuso, o bloco quadrado de compressão de espuma é formado. A grande redução do volume da espuma conduz à reciclagem da espuma.

Dois tipos de compactador de isopor a frio

Oferecemos dois tipos de densificadores de espuma EPS para atender às diferentes necessidades dos clientes.

1. Tipo vertical

A porta de alimentação de uma máquina compactadora vertical de isopor fica na parte superior da máquina, que precisa elevar a matéria-prima até a altura.

Especificação (compactador vertical)

| Modo | SL-300 | SL-400 |

| Tamanho da máquina | 3000*1400*1400mm | 4600*1600*1600mm |

| Tamanho de entrada | 1100*800mm | 1200*1000mm |

| Potência do motor | 11 kW | 22 kW |

| Saída | 150kg/hora | 250kg/hora |

2. Tipo horizontal

A altura da porta de alimentação de um compactador de isopor horizontal fica nivelada com o solo, o que é mais conveniente para a alimentação.

Especificação (tipo horizontal)

| Modo de tipo horizontal | SL-300 | SL-400 |

| Tamanho da máquina | 3000*1700*900mm | 4600*2800*1200mm |

| Tamanho de entrada | 830*760mm | 870*860mm |

| Potência do motor | 15 kW | 22 kW |

| Saída | 150kg/hora | 300kg/hora |