Como as espumas plásticas residuais podem ser convertidas de forma eficiente em pellets recicláveis? Este artigo enfoca máquinas de reciclagem de isopor e processos de reciclagem de espuma para orientar os recicladores de isopor.

Por que nos escolher?

- Nossas máquinas de reciclagem de espuma possuem especificações completas para atender às suas diferentes necessidades. Eles são adequados para todos os tipos de produção de reciclagem de espuma em larga, média e pequena escala.

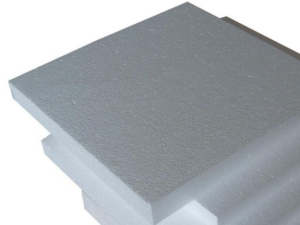

- Ampla gama de aplicações: várias formas de EPS, EPP, EPE, XPS e outras matérias-primas de espuma podem ser recicladas.

- Alto desempenho, capacidade de 150-300kg/h, alta eficiência. Também podemos fornecer máquinas personalizadas se você tiver necessidades especiais.

- Economia de energia e proteção ambiental: Equipado com dispositivo de remoção de poeira, motor de alta eficiência, etc., que pode reduzir o consumo de energia e atender aos requisitos de proteção ambiental.

- Fácil Manutenção: O design humanizado da máquina de reciclagem de espuma é fácil de operar e manter. Enquanto isso, oferecemos serviço pós-venda completo e podemos fornecer suporte técnico.

- Alta qualidade dos produtos acabados: as partículas de espuma reciclada são uniformes e redondas, com boas propriedades físicas e alta pureza, podendo ser utilizadas diretamente na produção e processamento industrial.

Aplicações das máquinas de reciclagem de isopor

Máquinas de reciclagem de isopor são comumente usadas para processar resíduos de espuma de embalagens, construção, móveis, automotivo, agricultura e muitas outras indústrias, como lancheiras de espuma, embalagens de espuma de correio, colchões, estofamento de assentos de carro, painéis de isolamento de construção, filme de proteção de frutas, etc.

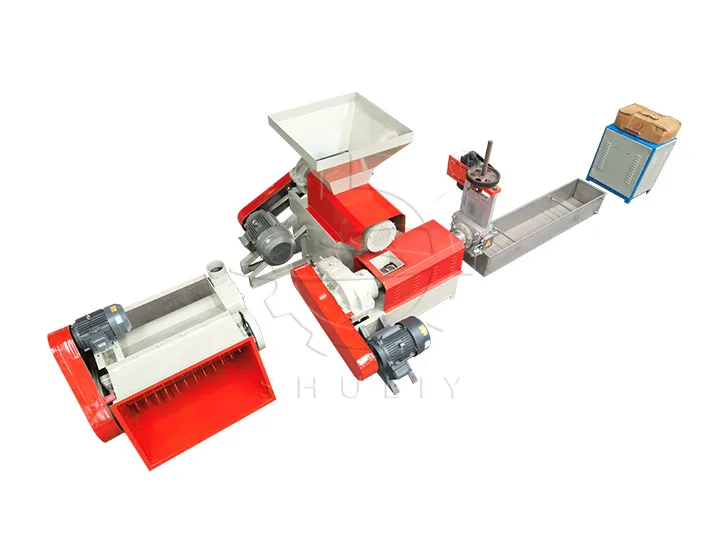

A linha de reciclagem de espuma EPS converte grandes pedaços de espuma descartada em pellets reciclados finos através dos processos de trituração, compactação e granulação. Quer se trate de reciclagem pós-consumo ou reciclagem industrial interna de EPS, nossas máquinas de reciclagem de isopor podem atender às suas necessidades de produção e os pellets de plástico acabados atenderão a altos padrões.

Como funciona a reciclagem de espuma de polietileno expandido?

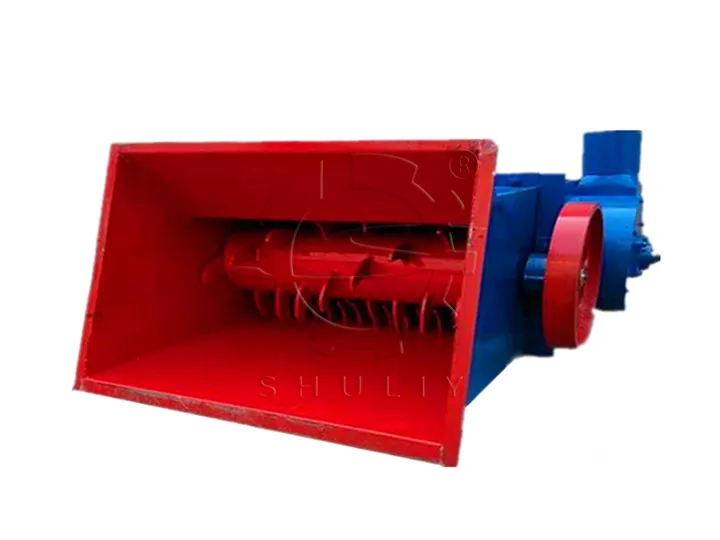

1. Esmagamento

A espuma plástica é grande, de densidade leve, fácil de quebrar e difícil de transportar, armazenar e processar. Portanto, use a trituradora de espuma para triturar as matérias-primas coletadas para pré-tratamento e obter blocos menores de isopor.

Shuliy triturador de poliestireno é feito de aço inoxidável de alta qualidade, durável e resistente à corrosão, e possui uma grande capacidade e alta produção.

- Capacidade: 250-500kg/h

- Potência: 5,5-11KW

- Material: aço inoxidável de alta qualidade

- Produtos Finais: Pedaços de espuma menores e uniformes

2. Prensagem a frio

Se precisar reduzir ainda mais o volume da espuma, você pode usar o compactador de isopor para comprimir os blocos de espuma triturados em blocos de espuma densos por pressão mecânica, o que facilita o transporte, armazenamento subsequente, etc.

Máquinas de briquetagem de EPS não requerem aquecimento, resultando em baixo consumo de energia; elas podem reduzir o volume de espumas plásticas em até 40 vezes, resultando em compressão eficiente; além disso, a prensagem a frio não altera as propriedades químicas do material, o que facilita o processamento subsequente.

- Capacidade: 150-250kg/h

- Potência: 11-22KW

- Produtos finais: Blocos de compressão de espuma de alta densidade

3. Fusão a Quente

Se for necessária uma densidade mais alta ou um estado fundido do bloco de espuma, a máquina de reciclagem de fusão a quente EPS é recomendada. O aparelho de fusão de isopor aquece a espuma até um estado fundido em alta temperatura e depois a extrusa para formar um bloco de espuma de alta densidade e baixo volume. Além disso, o processo de fusão e aquecimento pode filtrar impurezas e melhorar a pureza dos plásticos reciclados.

Densificador de espuma é adequado para processamento de reciclagem profunda. É fácil de operar, economiza energia e é ambientalmente amigável, podendo obter blocos de espuma de maior densidade de forma eficiente; equipado com um sistema de filtro de escória para remover impurezas de forma eficaz.

- Capacidade: 100-250kg/h

- Potência: 15-22KW

- Produtos finais: Lingotes de isopor de alta densidade e alta pureza

4. Pelotização

Use uma máquina de pelletização de EPS ou uma máquina de extrusão de EPE para converter blocos de espuma processados em pellets reciclados uniformes através de derretimento, extrusão, resfriamento e corte. As granulações plásticas recicladas podem, então, ser usadas diretamente na fabricação e processamento de novos produtos plásticos.

A escolha de um granulador de isopor estável está relacionada à qualidade dos pellets acabados. Nossos granuladores de espuma são estáveis e resistentes a altas temperaturas e estão equipados com um bom sistema de filtragem, o que pode reduzir o número de substituições de filtros e paradas de máquinas. O alto grau de automação, fácil de operar.

- Capacidade: 150-375kg/h

- Potência: 15-22KW

- Peças: extrusora de espuma, tanque de resfriamento, máquina de corte de plástico dana

- Produtos Finais: Partículas de espuma de alta pureza, não poluentes, estáveis e homogêneas

Conclusão

A conversão de resíduos de espuma em pellets reciclados requer trituração, compressão, granulação, etc. Shuliy, como equipe profissional, tem se dedicado a criar a solução certa de reciclagem de isopor para nossos clientes. Se você tiver alguma dúvida, entre em contato conosco, seja bem-vindo!