How to profit efficiently from plastic film recycling? Shuliy’s plastic film recycling machines are ideal for small, medium, and large-scale recyclers and recycled plastic manufacturers. With a high processing capacity of 100–500 kg/h, durable materials, stable performance, user-friendly design, and excellent after-sales service, our plastic film recycling line helps businesses improve efficiency, reduce costs, and generate high returns from waste films. Whether you are starting or upgrading your recycling operation, Shuliy provides reliable machinery to turn plastic waste into valuable resources.

Application of Plastic Film Recycling Machines

Our plastic film recycling machine widely applies to a variety of films, such as PP, PE, LDPE LLDPE, HDPE, PC, PET, ABS, HAPE, PVC, EPS, etc. Some common plastic film materials are as follows:

| Material Type | Common Sources | Notes |

|---|---|---|

| LDPE Film | Packaging film, plastic bags | Soft, flexible, widely used |

| HDPE Film | Grocery bags, industrial wraps | Stronger and stiffer than LDPE |

| LLDPE Stretch Film | Pallet wrap, stretch wrap | Common in logistics and warehouses |

| Agricultural Films | Mulch film, greenhouse covers | Often heavily contaminated with soil |

| Shrink Film | Product packaging shrink wrap | Requires de-inking if printed |

| Printed PE Films | Food packaging, branded film rolls | May need ink removal in washing process |

| Garbage Bags | Household and industrial trash bags | Usually post-consumer waste |

| Construction Films | Insulation film, barrier film | Can include additives or mixed layers |

| Post-Consumer PE Waste | Recycled from households or landfill sorting | Often mixed and contaminated |

| Industrial Film Waste | Factory edge trims, defective film rolls | Usually cleaner, easier to recycle |

Whether post-consumer, or post-industrial plastic films, they all can be reprocessed by our plastic bag recycling machines to become granules for recycling use, including materials with high contamination levels, such as sand, soil, oil, and organic residues. The end granules, such as recycled polypropylene pellets, recycled bubble wrap, recycled stretch film, etc., can achieve purities of over 98%, making them suitable for a wide range of high-quality reuse applications.

Due to the different types of recycling materials, the configuration of each PE film recycling line is different. Please contact us for sepecific plastic bag recycling machine price and more details! Besides, customization service is available according to your requirements.

Features & Benefits of These Plastic Film Recycling Machines

- Matumizi ya chini ya nishati, pato la juu, mwonekano mzuri, vitendo na kuegemea;

- Uzalishaji wa wingi kwa CHEMBE za filamu za plastiki, ufanisi mkubwa na kuokoa kazi.

- Aina mbalimbali za mashine zinazohusiana ni hiari. Seti ya mashine za kuchakata filamu za plastiki zinaweza kuchaguliwa na kununuliwa kupitia huduma ya kuacha moja.

- We can customize many specifications according to your needs. And we have successful cases from 100kg/h to 500kg/h.

- Mipango tofauti ya kusafisha, michakato ya kusafisha, mipango ya kuchakata tena, na mipango ya tovuti hutolewa kwa ajili yako kulingana na hali yako halisi.

- Miundo na mapendekezo maalum yanapatikana kulingana na mahitaji yako.

- Ni maana muhimu kwa ulinzi wa mazingira.

Video of Plastic Film Recycling Machines in Factories

The Working Process of Plastic Film Recycling Line

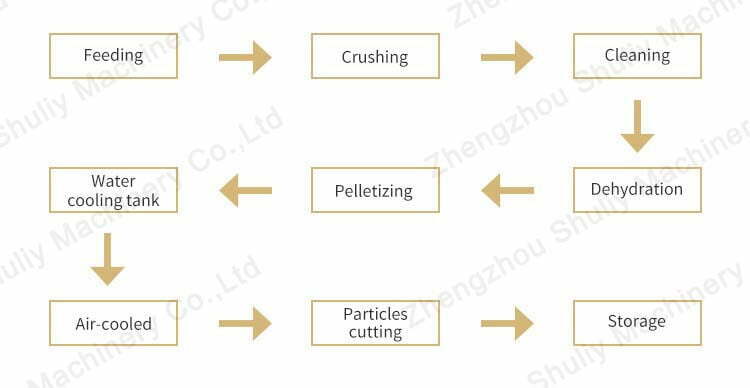

The process of plastic wrap recycling and reprocessing has some slight differences because of different materials. But the main steps are the same.

- The raw materials will be transported into a plastic bag shredder and washing machine by belt conveyor to be crushed and washed.

- The crushed film flakes are cleaned throughout in a sink.

- Then vertical type dewatering machine puts material out and dries it.

- Dried film scraps go along with the climbing conveyor into the automatic feeding machine. Because soft films are very light, it’s not convenient to send them into a plastic pellet-making machine directly. So it needs an automatic feeding machine to help.

- Then, the plastic film granulator extrudes long strips. Next, cooling soft strips in the cooling tank, cutting them into granules by the cutter. Then collecting these materials in a storage bin. And finally packaging these granules into bags.

Plastic Film Recycling Machines Involved in HDPE/LDPE Film Recycling Line

Conveyor ya ukanda is an fully automatic device to convey plastic waste to the plastic bag shredder, improving stretch film recycling efficiency and reducing manual costs.

Step 1: Automatic feeding machine

- Convey the plastic films into plastic crusher

- Optional adjustable motor to control the speed.

- Height of the frame can be adjusted

- Can be customized according to requirements

Shredder ya filamu ya plastiki crushes plastic films into smaller uniform pieces that are easy to clean and pelletize. The crushing machines adopts anti-tangling design, no clogging, no jamming, the highest efficiency up to 1t/h! Additionally, it is made of high-quality steel and is durable.

Step 2: Plastic Film Crusher

- Hydraulic lift divices

- Material: 60 Si2Mn

- Capacity: 600-1200 kg/h

- Adopt ball bearing, fixed center, balanced operation

- Unique multistep knives, increase the crushing rate.

Tangi ya kuosha osha tena nyenzo zilizovunjika kote na imewekwa na sahani za meno ili kulazimisha chip za plastiki kusonga mbele upande mwingine.

Step 3: Plastic Scrap Washing Machine

- Scientific design, thorough cleaning

- Easy to operate, save time and effort.

- Can be perfectly matched to plastic recycling lines.

- Length: 15-20 m.

Kausha wima kwa ajili ya chips filamu za plastiki ni pamoja na vifaa vya kusafisha nguvu swirling, kuwasilisha moja kwa moja, high-speed centrifugal upungufu wa maji mwilini, nk Kwa hiyo, mashine ya plastiki dewatering inaweza kupunguza maji na kavu vifaa kwa muda mfupi.

Step 4: Vertical stuff-fetching dryer

- Drying degree is as high as 98%

- High-speed extration and centrifugal dehydration

- Automatically feed and discharge the material at one time

Automatic force feeder machine helps soft materials like plastic film enter into a plastic pelletizer machine, avoiding tangling or clogging.

Step 5: Forced Feeder Machine

- Autonomous forced pressure

- Reduce labor

- Safe production

- Increase pellet output by 20-30%

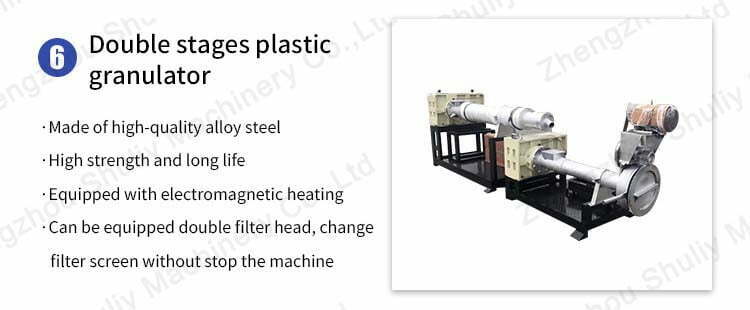

The mashine ya granulator ya plastiki ni mashine kuu ya mstari mzima wa kuchakata plastiki. Ni kifaa cha kuyeyusha na kutoa polyethilini na polypropen kwenye vipande virefu. Inaweza kukabiliana na filamu ya plastiki, mifuko ya bitana, mifuko ya zamani ya kusuka, mifuko ya ufungaji, kamba ya kuunganisha, nk.

Tangi ya baridi is mainly used for cooling soft strips, making them shaped and hard.

Pellet cutting machine will cut cooled long strips into small granules by hard alloy hob, convenient to store and secondary use.

There is a pump underneath the pipa la kuhifadhia that can continuously suck plastic particles into the inside of the machine.

PP PE Film Washing Line Layout in the Recycling Plant

The complete plastic film recycling line is about 40m long and can be operated by only 2-3 people. Shuliy can provide you with a free placement design according to your space, budget and so on. Please feel free to contact us for help!

https://youtu.be/9dIUNzOCbLw

Safari ya shambani ni wazo nzuri wakati wa kununua mashine ya kuchakata filamu ya plastiki

Tunapendekeza uje kwa kampuni na kiwanda chetu ikiwa unataka kuwekeza katika vifaa vya kuchakata filamu za plastiki. Tunaweza kuzungumza ana kwa ana na kukupanga kwenye kiwanda chetu ili kuona mashine za kuchakata kwa karibu. Safari ya shambani ni muhimu na inaweza kukusaidia kujifunza zaidi kuhusu vipande vya vifaa. Kampuni yetu imekuwa ikijishughulisha na vifaa vya kuchakata filamu za plastiki kwa zaidi ya miaka 10. Na tumepokea maagizo kutoka duniani kote. Ziara ya uga ni ukaguzi angavu sana. Unaweza kufikiria chaguo zako na mapendekezo yetu kwa kina, kama vile ukubwa wa tanki la kuoshea maji, aina ya mashine ya kusaga filamu ya plastiki, ambayo mashine hununua, n.k.

Kwa nini tunahitaji mashine za kuchakata filamu za plastiki?

Bidhaa za plastiki zimekuwa sehemu ya lazima ya maisha katika miaka ya hivi karibuni. Uzalishaji wa plastiki unafanywa kutoka mafuta ya petroli. Kuungua kwa plastiki kutazalisha gesi yenye sumu ambayo ni mbaya kwa wanadamu na mazingira asilia. Kwa hiyo, kushughulika na bidhaa za plastiki kwa njia sahihi ni muhimu. Kiwanda cha mashine ya kuchakata tena plastiki huwezesha matumizi ya kuchakata tena plastiki. Laini ya kuchakata tena ya plastiki yenye granulators ya plastiki inaweza kutengeneza pellets za plastiki kwa ajili ya kuchakata tena.