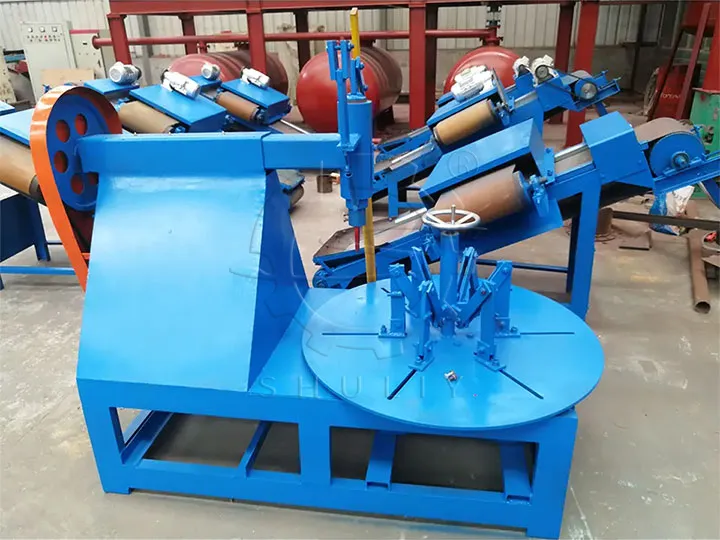

Shuliy Machinery inatoa mashine mbalimbali maalum za kukata matairi ili kuboresha ufanisi wa urejeleaji wa matairi taka. Miongoni mwao, kipanga upande wa matairi kimekuwa chaguo maarufu kwa biashara za urejeleaji wa matairi kutokana na muundo wake mdogo, utendaji wa kuaminika, na matokeo sahihi ya kukata. Mashine hii imeundwa kutenganisha pande za matairi kutoka kwa mguu wa matairi yaliyotumika, na kufanya kukata zaidi au kutoa nyuzi za chuma kuwa rahisi zaidi na ya gharama nafuu.

Vad är däckets sidoväggskärare?

Bead ya tairi ina nyuzi za chuma zilizojazwa kwa wingi, na kuifanya kuwa ngumu sana na vigumu kuipitia moja kwa moja. Bila matibabu sahihi ya awali, inaweza kuharibu vifaa vya kukata au kusaga. Ili kushughulikia hili, mtengenezaji wa pete ya tairi hutumiwa kuondoa eneo la bead kwa usalama.

Kort sagt, däcksidoväggskärare (även känd som däckringkärnare eller lastbilsdäcksidoväggskärare) används för att:

-

Skära av sidoväggarna från däckkronan eller slitbanan.

-

Möjliggör ytterligare däckskärning och trådseparation.

-

Minska däckvolymen för enklare hantering och transport.

Once the tire sidewalls are removed, they can either be processed into strips using a tire strip cutter or sent to a steel wire separator for wire extraction, depending on the recycling process requirements.

Tillämpning av däckets sidoväggskärare

Mashine yetu ya kukata ukuta wa tairi imeundwa mahsusi kushughulikia aina zote za tairi < 1200 mm, ikiwa ni pamoja na tairi za malori, tairi za magari, na kadhalika. Inaweza kutumika katika sekta zifuatazo:

- Däckåtervinningsanläggningar

- Tillverkning av gummiprodukter

- Verkstäder för utvinning av ståltråd

- Skrotbearbetningsgårdar

Tafadhali jisikie huru kuwasiliana nasi na kutuma vifaa vyako vya malighafi, na tunaweza kupendekeza na kubinafsisha mashine inayofaa ya kukata ukuta wa upande wa tairi kwa mahitaji yako.

Huvudfunktioner för vår däckringklippmaskin

- Bred kompatibilitet: Kan hantera olika storlekar av personbils- och lastbilsdäck.

- Hög effektivitet: Separera snabbt sidoväggarna med rena, släta kanter.

- Hållbara blad: Slitstarka legeringsblad säkerställer lång livslängd.

- Enkel driftLätt att använda med minimal träning krävs

- Stabil struktur: Kompakt, tungt ramverk säkerställer säker och stabil skärning.

- Låg underhållDesignad för långsiktig användning med minimal skötsel

- Kostnadseffektiv: Minskar arbetskostnader och ökar bearbetningshastigheten.

Teknisk data för sidoväggsdäckskärare

| Jina | Skärare för däckväggar |

| Uwezo | 40 stycken/h |

| Kraften på motorn | 4+0.75 KW |

| Arbetsområde | däck 650-1200 mm |

| Ukubwa wa Mashine | 1.8*1.3*1.6 m |

Hur fungerar däcksidoväggsklipparen?

Däcket placeras platt på den roterande plattformen och säkras ordentligt. Efter att maskinen har slagits på använder operatören kontrollsystemet för att justera positionen för det legerade skärverktyget och aktivera plattformens rotation. När plattformen snurrar rör sig bladet gradvis inåt och skär noggrant längs bead eller sidovägg för att uppnå en ren separation.

Däcksidoväggskärare till salu

Looking for a tire sidewall cutter for sale? Shuliy offers cost-effective, high-quality machines ready for shipment worldwide. Whether you’re starting a new recycling plant or upgrading your current system, our tire sidewall cutting machine is a solid investment. If you’re interested, check out our semi-automatic waste tire recycling line to see how the tire sidewall cutter works as part of an optimized recycling workflow, or please feel free to contact us!