Maskin ya granulator ya plastiki pia inaitwa mashine ya kutengeneza granules za plastiki. Ni vifaa vya kuyeyusha na kutoa chips za taka za PP (polyethylene) au PE (polypropylene) ili kutengeneza granules za plastiki. Injini kuu ya granulator ni extruder, ambayo inajumuisha mfumo wa extrusion, mfumo wa uhamasishaji, na mfumo wa kupasha moto na baridi. Plastiki iliyovunjwa, kusafishwa, na kavu inaweza kuwekwa moja kwa moja kwenye mashine ya kutoa. Kisha, strip za plastiki zilizotolewa kawaida zinahitaji kupozwa katika tank ya kupoza na kukatwa kuwa pellets na mashine ya kukata pellets. Mashine ya kutengeneza pellets za filamu za plastiki ni sehemu muhimu ya kiwanda cha urejeleaji wa plastiki. Inafaida kwa kukuza kwa nguvu rasilimali zinazoweza kurejelewa na kubadilisha taka kuwa hazina.

Video ya kazi

Nyenzo zinazotumika kwa kuchakata granulator

Muundo wa mashine ya kutengeneza granles za plastiki huiruhusu kusindika kwa ufanisi aina mbalimbali za taka kwenye pellets. Kwa plastiki taka tunazigawanya katika plastiki za baada ya watumiaji na baada ya viwanda, zote mbili zinaweza kuchakatwa katika mashine zetu za kuchakata tena.

Nyenzo za kuchakata tena baada ya viwanda: Ili kuokoa gharama za malighafi na kufikia uchumi wa mzunguko, wazalishaji wengi wa plastiki kama watengenezaji wa mifuko ya plastiki hurejesha vipandikizi vyao na kisha kuendelea kusindika pellets wanazozalisha kuwa bidhaa za plastiki. Plastiki hizi za baada ya viwanda ni pamoja na kukatwa kwa mifuko ya HDPE/LDPE, filamu-on-roll, filamu mbovu na bidhaa za mifuko, mifuko ya zipu iliyochapishwa, mabomba yenye kasoro ya HDPE ya PVC, PP/HDPE/LDPE regrind, bomba za umwagiliaji laini za HDPE, n.k. .

Nyenzo za kuchakata baada ya mlaji: Bidhaa zote za plastiki zilizotumika na kutupwa kama vile chupa za plastiki zilizotumika, mifuko ya plastiki, mita zilizoachwa, sehemu za gari, vyombo vya chakula, ngoma za kemikali, palati za plastiki, kamba za PP, uvimbe wa plastiki, jeri, mirija ya vipodozi, vifuniko vya mapovu. , filamu za laminated / safu nyingi, vifaa vya kufunga vinavyobadilika na kadhalika.

Mashine ya granulator ya plastiki inauzwa

Kama mashine kuu ya mchakato wa uzalishaji wa granule za plastiki, vifaa hivi vinatumika kwa aina mbalimbali za pelletizing. Muonekano wa granulators kwa ajili ya kushughulikia nyenzo tofauti ni sawa, lakini sio sawa. Vipengele vya ndani vinahitaji kurekebishwa kulingana na nyenzo maalum, kama vile kipenyo cha screw ya ndani, umbali kati ya screw na ukuta wa silinda, na urefu wa screw.

Kwa hiyo, mashine moja iliyorekebishwa inalingana na aina moja ya nyenzo. Vifaa vilivyorekebishwa vinafaa zaidi kwa mali ya malighafi yako. Kwa hivyo unaweza kuwasiliana nasi ili kupata maelezo zaidi kwa kutuambia ni nyenzo gani ungependa kuweka pelletize. Kando na hilo, tunaauni huduma za ubinafsishaji kulingana na mahitaji yako mahususi ya kuchakata tena.

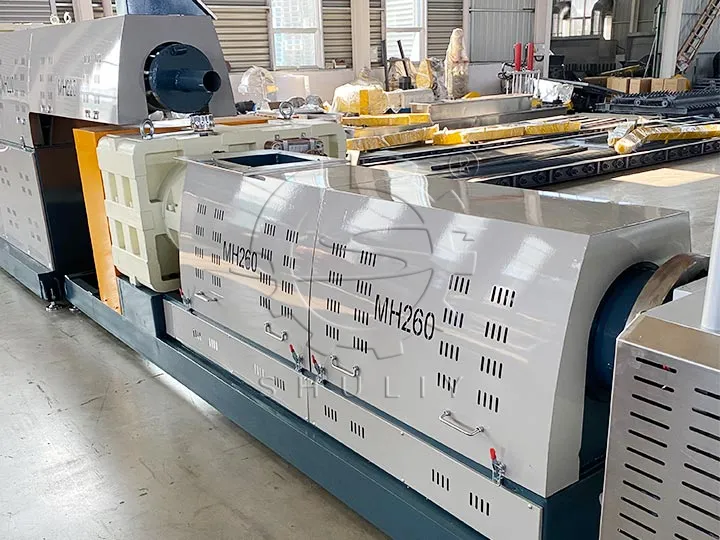

Maonyesho ya mashine ya kiwandani

Vipengele na faida za vifaa vya plastiki vya granulation

- Ubunifu wa kipekee, utendaji mzuri, kelele ya chini, kukimbia kwa utulivu, operesheni rahisi

- Mchakato rahisi, teknolojia ya hali ya juu, na yanafaa kwa ajili ya plastiki taka mbalimbali

- Parafujo na pipa ni upinzani wa kuvaa, kudumu, pato la juu.

- Mashine ya granulator ya plastiki inaweza kukabiliana na tani 2-30 za plastiki taka kwa siku.

- Mashine kuu na msaidizi zilizojumuishwa, ufungaji rahisi, alama ndogo ya miguu, utendaji wa gharama kubwa.

- Tumia msuguano wa juu wa shinikizo inapokanzwa bila kukatizwa, hali ya joto ya kazi nyingi, iliyo na mfumo wa joto usiobadilika.

- Usihitaji kuongeza joto kila wakati, kupunguza matumizi ya nishati kwa 30-40%.

- Uendeshaji wa hali ya juu, uingiliaji mdogo wa wanadamu

- Huduma ya ubinafsishaji inapatikana.

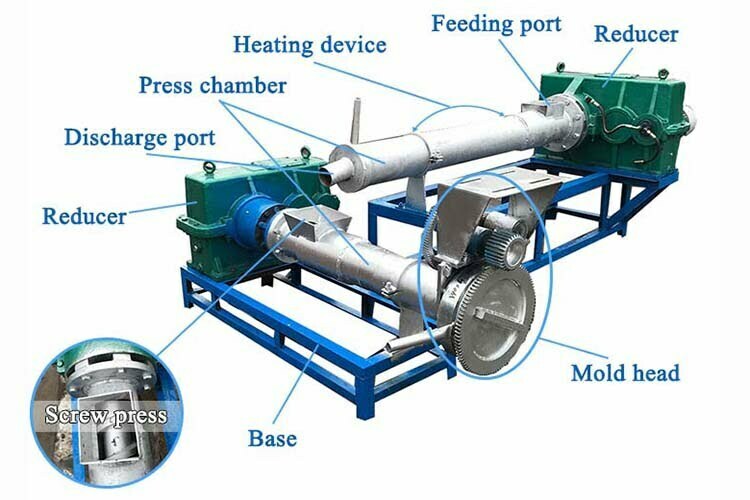

Muundo wa mashine

Muundo wa mashine ya kutengeneza chembe za plastiki unajumuisha kipunguza, mlango wa kulisha, kifaa cha kupokanzwa, chumba cha vyombo vya habari, mlango wa kutokwa, vyombo vya habari vya screw, kichwa cha ukungu, msingi na sehemu zingine.

Reducer ni reducer yenye uso mgumu wa gia. Ubora wake ni muhimu sana kama sehemu muhimu ya extruder ya plastiki. Kwa sasa, kiwango cha ubora wa reducers za kawaida sokoni ni reducer ya zamani ya konokono <common reducer <semi-hard gear surface reducer <hard gear surface reducer.

Kuna aina mbili kuu za mold head za kutoa plastiki, kichwa cha umeme na kichwa cha majimaji. Screen ya filer ya kichwa cha mold ya majimaji inaweza kubadilishwa bila kuacha mashine. Kwa nyenzo zenye uchafu mwingi, majimaji ni bora zaidi. Lakini gharama yake pia ni ya juu zaidi. Mfano wa mashine ya granulator ya plastiki inagawanywa hasa kulingana na kipenyo cha screw. Screw imetengenezwa kwa chuma cha 45#steel, 40CR, 38CRSI. Mfano wa vifaa vya granulation ya plastiki unagawanywa hasa kulingana na kipenyo cha screw press. Huduma za desturi za chrome plating, nitriding, na michakato mingine zinapatikana kulingana na sifa zao za usindikaji wa plastiki.

Mfumo wa kupokanzwa wa mashine ya granulating ya LDPE/HDPE

Njia ya kupokanzwa ya extruder ya plastiki imegawanywa katika pete ya kupokanzwa ya alumini ya kutupwa, pete ya kupokanzwa tube ya quartz, pete ya joto ya kauri, pete ya joto ya umeme. Miongoni mwao, athari bora ya kupokanzwa ni inapokanzwa kwa umeme. Pete ya kupokanzwa ya alumini ya kutupwa inahitaji dakika 30-40 ili kupokanzwa, wakati pete ya joto ya sumakuumeme inahitaji dakika 15-20. Kupokanzwa kwa umeme kunaweza kuongeza joto haraka. Na ina athari nzuri ya joto ya mara kwa mara, inayoendesha kwa utulivu. Lakini siofaa kwa usindikaji wa vifaa vya povu. Njia ya kupokanzwa inapaswa kuzingatiwa kulingana na malighafi na rangi ya bidhaa ya mwisho.

Kanuni ya kazi ya mashine ya kutengeneza granule ya plastiki

- Washa mashine ya kuchanja ya HDPE/PP/PVC. Kuangalia mashine kama kuna sauti isiyo ya kawaida au mtetemo. Ikiwa sivyo, weka kwenye matumizi.

- Makini na preheating mashine ya plastiki granulator ili kuyeyusha plastiki. Plastiki iliyoyeyuka itageuka kuwa nyeusi ikiwa hali ya joto ni ya juu sana. Wakati joto la chini haliwezi kuyeyuka plastiki.

- Ni bora kuwa na mashine ya kulisha kiotomatiki ili kulisha chips za plastiki kwenye vifaa vya chembechembe za plastiki kwa sababu nyenzo za filamu ya plastiki ni nyepesi sana, si rahisi kulisha.

- Vipande vya filamu vya plastiki vitayeyushwa na kushinikizwa kwenye injini kuu, kisha kusukumwa pamoja na screw kwenye injini ya msaidizi. Hatimaye, Nyenzo iliyoyeyuka itatolewa kutoka kwa injini ya msaidizi kwa namna ya vipande vya plastiki.

- Weka tank ya baridi chini ya kichwa cha mold ili vipande vya plastiki vya moto vipoe kwenye tank na sura.

Ni nini kinachopaswa kuzingatia wakati wa kutumia vifaa vya granulator ya plastiki?

- Ndani ya mashine haipaswi kuwa na mabaki ya chuma au mchanga mwembamba. Usiweke vitu vya chuma au vitu vingine karibu na ghuba ambapo kinaweza kuanguka kwenye mashine endapo mashine ya plastiki itaharibika, kusababisha msongamano au uharibifu.

- Opereta alipata mafunzo halisi kuhusu jinsi ya kuendesha mashine ya chembechembe. Kwa kuongeza, wanapaswa pia kujifunza muundo wa vifaa na taratibu za uendeshaji.

- Kudhibiti joto la maji la tank ya baridi. Kwa sababu vipande vya plastiki vitavunjwa ikiwa hali ya joto ni ya chini sana. Wakati joto la juu haliwezi kufanya vipande vya plastiki vipoe na kuunda vizuri, na vipande vinaweza kushikamana.

- Plastiki iliyoyeyuka inapaswa kutolewa kwa vipande sawasawa kabla ya kuingia kwenye mashine ya kukata pellet ya plastiki. Vipande visivyo na usawa vinaweza kuharibu kikata pellet ya plastiki. Mashimo ya kichwa cha mold yanaweza kufungwa na uchafu ikiwa ukanda wa extruded ni nyembamba au umevunjika. Kwa hivyo unahitaji kuchukua nafasi ya skrini ya kichungi.

Vigezo vya mashine ya kutengeneza CHEMBE za HDPE

| Aina | 105 | 125 | 135 | 150 | 180 | 200 | 220 |

| Kipenyo cha screw | 105 mm | 125 mm | 135 mm | 150 mm | 180 mm | 200 mm | 220 mm |

| Kasi ya spindle | 50-70/dak | 50-70/dak | 40-50/dak | 40-50/dak | 40-50/dak | 40-50/dak | 40-50/dak |

| Nguvu kuu ya gari | 18.5kw | 30kw | 37kw | 37kw | 55kw | 75kw | 90kw |

| Kipunguzaji (gia ngumu) | 200 | 225 | 250 | 250 | 280 | 315 | 330 |

| Uzito | 1.3T | 1.8T | 2T | 2T | 2.2T | 2.8T | 3.2T |

| Ukubwa | 2.4*0.7*0.7 | 2.6*0.7*0.7 | 2.8*0.7*0.7 | 3.0*0.7*0.8 | 3.2*0.7*0.8 | 3.5*1*1 | 3.8*1.2*1 |

| Pato | 150kg/saa | 180kg/saa | 200kg/h | 300kg/h | 350kg/saa | 380kg/saa | 420kg/saa |

Tuna mifano 7 ya mashine za granulator ambazo unaweza kuchagua. Tofauti kubwa kati ya mashine 7 ni pato. Pato ni 150kg/h, 180kg/h, 200kg/h, 300kg/h, 350kg/h, 380kg/h na 420kg/h mtawalia. Vile vile, pato tofauti linalingana na bei tofauti. Ikiwa una kiwanda kikubwa cha kuchakata plastiki, tunapendekeza ununue mashine za 380kg / h au 420kg / h. Pia tutakupa bei nzuri zaidi. Pili, unahitaji kuzingatia eneo la mmea wako na saizi ya mashine. Kama unaweza kuona, uzalishaji mkubwa unamaanisha saizi kubwa. Kwa mfano, ukubwa wa mashine yenye pato la 150kg/h ni 2.4 * 0.7 * 0.7, wakati ukubwa wa mashine yenye pato la 420kg/h ni 3.8 * 102 * 1. Ikiwa eneo la mmea wako ni ndogo sana, haifai kwa mashine kubwa zaidi, au unaweza kurekebisha ukubwa wa mmea wako.