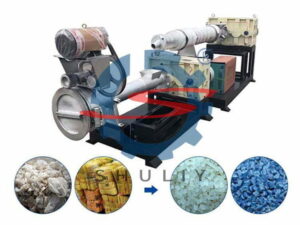

EPS foam densifier inajulikana pia kama mashine ya briquetting ya EPS na kompaktori ya styrofoam, inayotumika kwa ajili ya kubana povu, kama vile EPS au EPE plastiki za povu. Kanuni ya kufanya kazi ni kubana povu la EPS kuwa vizuizi vya tii kwa njia ya mitambo ya kubana screw. Kulingana na sifa za malighafi, uwiano wa kubana unaweza kufikia mara 40, ili kupunguza kiasi cha povu. Vizuizi vya povu vilivyo bunwa ni rahisi kwa usafiri wa umbali mrefu na uhifadhi, ambavyo vinapunguza gharama za usafiri na nafasi ya uhifadhi. Mbali na kompaktori ya styrofoam, pia tunatoa mashine ya kuyeyusha povu kwa joto kupunguza kiasi cha taka za EPS au EPE plastiki za povu.

Inaangazia kipenyo cha povu cha EPS

- Baada ya kukandamiza kiasi cha povu ya EPS mara 30-40 ndogo kuliko hapo awali, wiani wa povu ni kubwa, na vitalu vya povu hukatwa kwa urahisi, kuhifadhiwa, na kusindika tena. Okoa nafasi ya kuhifadhi na gharama za usafirishaji na uhifadhi

- Kompakta ya styrofoam ina vifaa vya utaratibu wa kabla ya kusagwa ili kuhakikisha ufanisi wa kazi na kudumisha matumizi ya chini ya nishati. Saizi tofauti za bandari za kulisha zinaweza kuchaguliwa kwa matibabu ya kushinikiza baridi.

- Miundo mikubwa inaweza kufanya kazi kwa usawa na ukanda wa conveyor ili kuboresha ufanisi wa uzalishaji.

Kompakta ya EPS inafanya kazi vipi?

Kompakta baridi ya povu ya EPS inabana plastiki za povu kulingana na kanuni ya mzunguko wa screw na compress baridi. Katika operesheni, operator anahitaji tu kutupa povu taka ndani ya hopper, na densifier ya povu ya EPS ina utaratibu wa kupasua ili kuponda kuzuia povu. Kisha utaratibu wa skrubu unakandamiza povu ndogo ya styrofoam/polystyrene kwenye kizuizi cha mgandamizo wa ujazo. Kuna kifaa cha kudhibiti shinikizo kwenye ncha ya mbele ya sehemu ya mgandamizo ili kurekebisha uwiano wa mgandamizo. Baada ya nyenzo kusindika na utaratibu wa screw, kuzuia povu ya mraba compressing block huundwa. Upunguzaji mkubwa wa kiasi cha povu unafaa kwa kuchakata povu.

Aina mbili za compactor baridi ya styrofoam

Tunatoa aina mbili za vidhibiti vya povu vya EPS ili kukidhi mahitaji tofauti ya wateja.

1. Aina ya wima

Bandari ya kulisha ya mashine ya compactor ya wima ya styrofoam iko kwenye sehemu ya juu ya mashine, ambayo inahitaji kuinua malighafi hadi urefu.

Maelezo (kompaktori ya aina wima)

| Hali | SL-300 | SL-400 |

| Ukubwa wa mashine | 3000*1400*1400mm | 4600*1600*1600mm |

| Ukubwa wa kuingiza | 1100*800mm | 1200*1000mm |

| Nguvu ya magari | 11kw | 22kw |

| Pato | 150kg/saa | 250kg/saa |

2. Aina ya usawa

Urefu wa bandari ya kulisha ya compactor ya styrofoam ya usawa ni sawa na ardhi, ambayo ni rahisi zaidi kwa kulisha.

Maelezo (kompaktori ya aina ya usawa)

| Njia ya aina ya usawa | SL-300 | SL-400 |

| Ukubwa wa mashine | 3000*1700*900mm | 4600*2800*1200mm |

| Ukubwa wa kuingiza | 830*760mm | 870*860mm |

| Nguvu ya magari | 15kw | 22kw |

| Pato | 150kg/saa | 300kg/h |