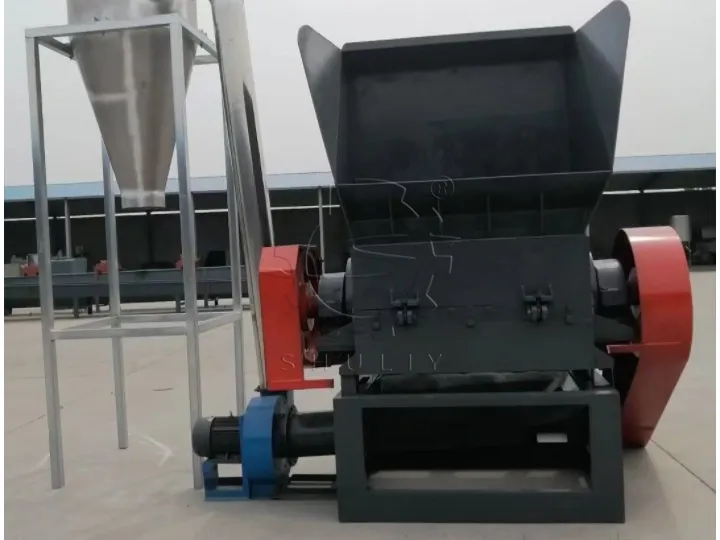

Na crescente indústria de reciclagem de plásticos, ter o equipamento certo pode melhorar significativamente a sua eficiência e a qualidade da produção. O nosso triturador de sacos plásticos é uma máquina de alto desempenho, especialmente projetada para triturar todos os tipos de filmes e sacos plásticos flexíveis, incluindo LDPE, HDPE e outros materiais de embalagem flexíveis. Quer esteja a processar resíduos pós-consumo ou sobras de filmes industriais, este triturador oferece uma solução poderosa e fiável.

O que é um triturador de sacos plásticos?

Um triturador de sacos plásticos é uma máquina que reduz o tamanho dos sacos plásticos em pedaços menores e uniformes, adequados para lavagem, secagem e reciclagem adicional. É uma parte crucial de qualquer linha de reciclagem de filmes plásticos, especialmente para materiais macios e leves que são difíceis de processar com trituradores convencionais.

A nossa máquina pode lidar com:

-

Sacolas de compras em LDPE e HDPE

-

Sacos de lixo e forros de lixo

-

Filmes esticados industriais

-

Filmes de embalagem de alimentos e embalagens plásticas

-

Filmes de mulching agrícola e coberturas de estufas

Principais características do nosso triturador e picador de sacos plásticos

-

Sistema de Corte de Alta Eficiência: Equipado com lâminas de rotação de alta velocidade e facas fixas, alcançando uma redução de tamanho consistente de plásticos macios.

-

Design Anti-Enrolamento: Otimizado para filmes finos e flexíveis que tendem a enrolar-se nos eixos — perfeito para sacos e filmes de embalagem.

-

Estrutura Robusta: Feito com aço resistente ao desgaste para garantir durabilidade e longa vida útil.

-

Tamanhos de Ecrã Personalizáveis: Permite tamanhos de saída ajustáveis dependendo dos seus requisitos a jusante.

-

Sistema Opcional de Transportador e Ventilador: Permite alimentação e descarga automatizadas, ideal para linhas de reciclagem integradas.

Especificações técnicas do nosso triturador de filme plástico

| Modelo | SLSP-600 | SLSP-800 | SLSP-1000 |

|---|---|---|---|

| Potência do Motor | 30 kW | 45 kW | 55 kW |

| Capacidade | 600–800 kg/h | 800–1000 kg/h | 1000–1200 kg/h |

| Matérias-primas aplicáveis | filme PE, filme LDPE, filme HDPE, filme de mulching agrícola, filme de estufa, sacos de plástico para compras, sacos de lixo, filme stretch, filme retrátil, filme impresso, embalagens de plástico macio, filme de embalagem | Mesma que à esquerda | Mesma que à esquerda |

| Tamanho final da saída | 40–50 mm (tamanho da tela ajustável) | 40–50 mm | 40–50 mm |

| Material da Faca | 60Si2Mn | 60Si2Mn | 60Si2Mn |

| Número de Facas Rotativas | 10 pcs | 10 pcs | 10 pcs |

| Largura da Caixa do Triturador | 600 mm | 800 mm | 1000 mm |

| Material do Quadro da Máquina | Aço inoxidável de alta qualidade | Aço inoxidável de alta qualidade | Aço inoxidável de alta qualidade |

| Aplicações Comuns | Picador de sacos plásticos, triturador de filme plástico, picador de filme stretch, triturador de flocos de plástico macio | Mesma que à esquerda | Mesma que à esquerda |

Nota: Modelos personalizados estão disponíveis com base nas suas necessidades de matéria-prima e capacidade.

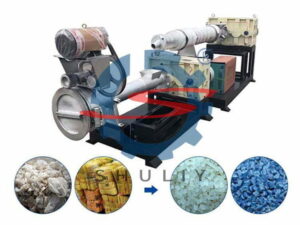

Como Funciona o Destruidor de Sacos Plásticos?

O triturador de sacos plásticos funciona alimentando materiais plásticos macios—como sacos de compras, filmes elásticos ou embalagens—em uma câmara de corte rotativa. Dentro da câmara, lâminas rotativas de alta velocidade trabalham em conjunto com lâminas fixas para fatiar e rasgar o plástico em flocos menores e uniformes.

O processo de trabalho inclui:

-

Alimentação: Sacos de plástico são carregados manualmente ou através de uma esteira transportadora.

-

Corte e Trituração: As lâminas rotativas cortam o material contra lâminas fixas, minimizando o entupimento e o enrolamento.

-

Dimensionamento: Uma peneira sob as lâminas filtra o material, permitindo a passagem apenas de flocos com o tamanho adequado.

-

Descarga: O plástico triturado é recolhido ou transportado diretamente para o sistema de lavagem ou peletização.

: Muitos modelos apresentam designs de lâminas anti-enrolamento e sistemas automáticos de reversão para evitar atolamentos—tornando-os ideais para plásticos macios e flexíveis.

Picador de filme plástico eficiente instalado em todo o mundo

A nossa máquina trituradora de filmes plásticos, conhecida pelo seu design anti-enrolamento, alta eficiência de trituração e compatibilidade com uma vasta gama de materiais plásticos macios, tem sido exportada com sucesso para países como Quénia, África do Sul, Arábia Saudita, México, etc. Tem ajudado os clientes a melhorar eficientemente a sua capacidade de reciclagem e a reduzir os custos de mão de obra, o que tem recebido feedback positivo consistente de clientes globais.

: Para apoiar nossos clientes, fornecemos serviços abrangentes de pós-venda, incluindo:

-

Instalação e formação no local

-

Garantia de qualidade de um ano

-

Orientação por vídeo e suporte online 24/7

-

Peças sobressalentes prontamente disponíveis

📩 Contacte-nos hoje para obter uma solução personalizada para o seu projeto de reciclagem de película plástica. Deixe-nos ajudá-lo a iniciar ou atualizar a sua linha de reciclagem com confiança! Também fornecemos esmagador de plástico rígido, triturador de esferovite e trituradores de garrafas PET.