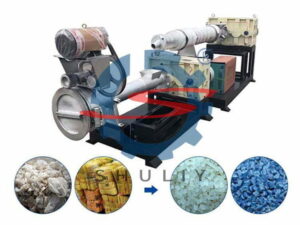

EPS造粒机是一种将废旧泡沫塑料或可发性聚苯乙烯(EPS)破碎和造粒的专用回收设备。 EPS造粒机设计合理,自动化程度高,技术先进,无污染。生产出来的塑料颗粒尺寸均匀、亮度均匀。生产的颗粒用途广泛,如墙体保温材料、产品包装材料、以及一些产品的辅助材料。

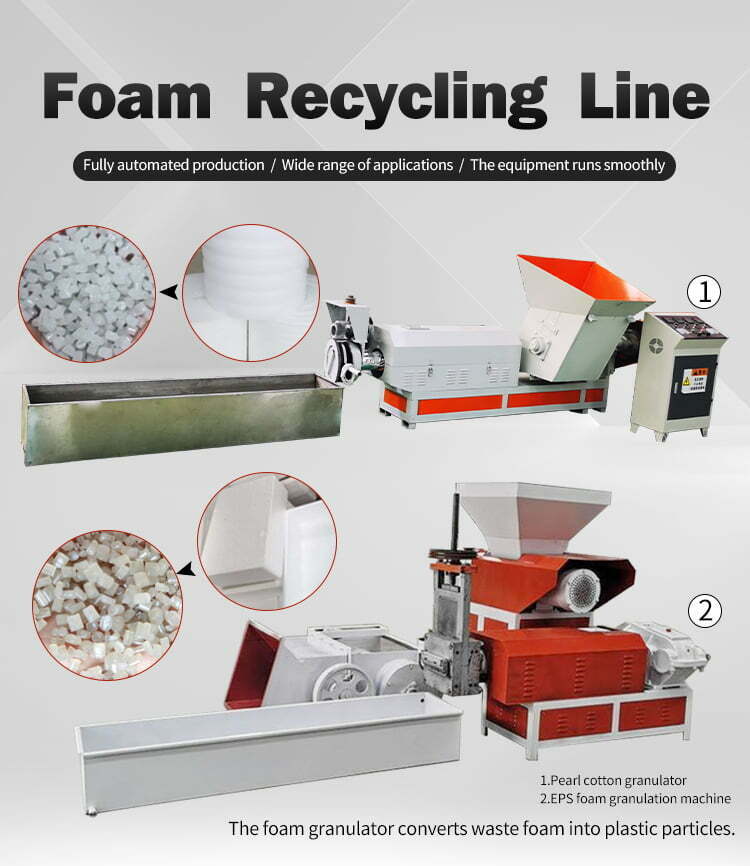

如今,可发性聚苯乙烯(EPS)的用量正在迅速增加。这些废旧聚苯乙烯泡沫塑料质量轻、体积大、耐老化、不易腐蚀,成为垃圾处理的一大难题。近年来,EPS泡沫回收越来越受到人们的关注,泡沫聚苯乙烯的回收前景广阔。 EPS造粒机经常用于塑料回收生产线,并在回收行业中越来越受欢迎。除了EPS泡沫造粒机外,我们还提供EPE/珍珠棉造粒机。

EPS造粒机应用

EPS泡沫造粒机用于将废弃快餐盒、家用电器、运输保护用保丽龙包装材料等中的泡沫进行加工,转化为回收的EPS颗粒。塑料泡沫加工工艺 EPS熔体增稠剂 也适用。这种再生塑料可用于生产各种绝缘材料、包装材料、玩具、电器等。

EPS造粒机的突出优点

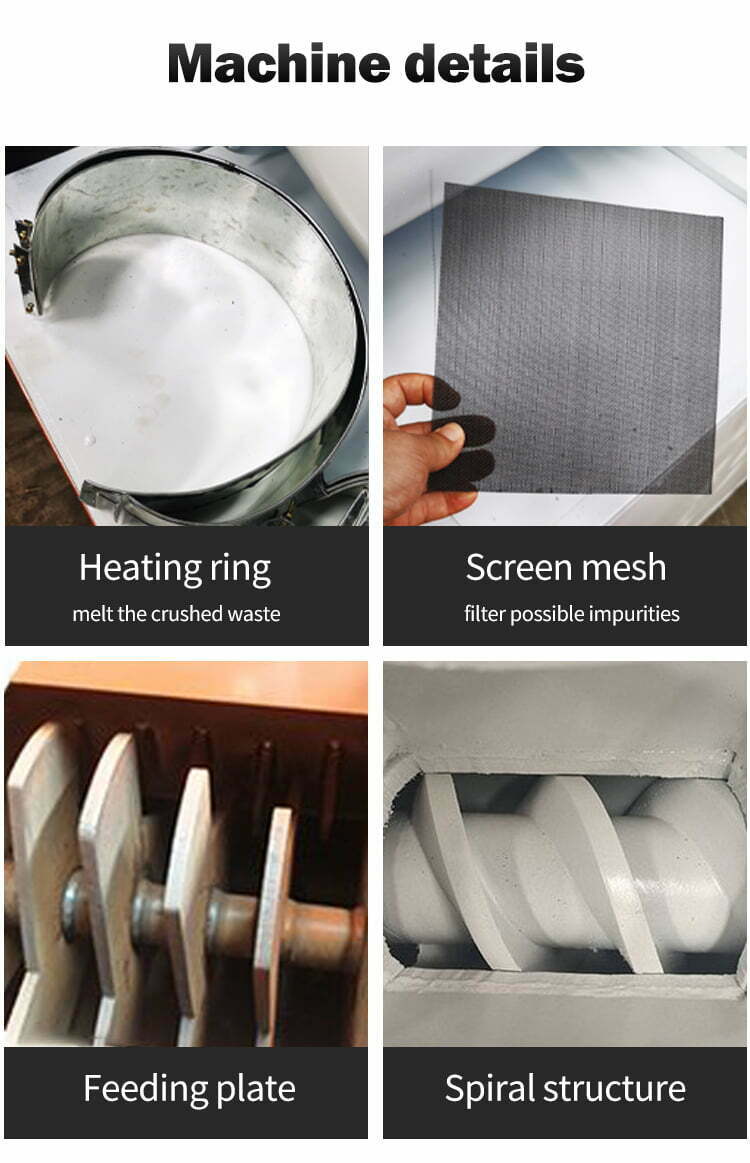

1、主副机螺钉采用热处理45#钢制成。具有良好的综合机械性能。

2、电机配有两台齿轮减速机,运行平稳,使用寿命长。

3、EPS泡沫造粒机采用锥形螺杆机筒,喂料量大,产量高。

4、主辅机配套使用。加热温度稳定,有效改善材料分子结构,透气性增强,颗粒质量显着提高。主机温度200摄氏度,辅机温度180摄氏度。

5、有两种加热方式可供选择。电磁(加热时间10-15分钟)、电热管/电热圈(30-40分钟)

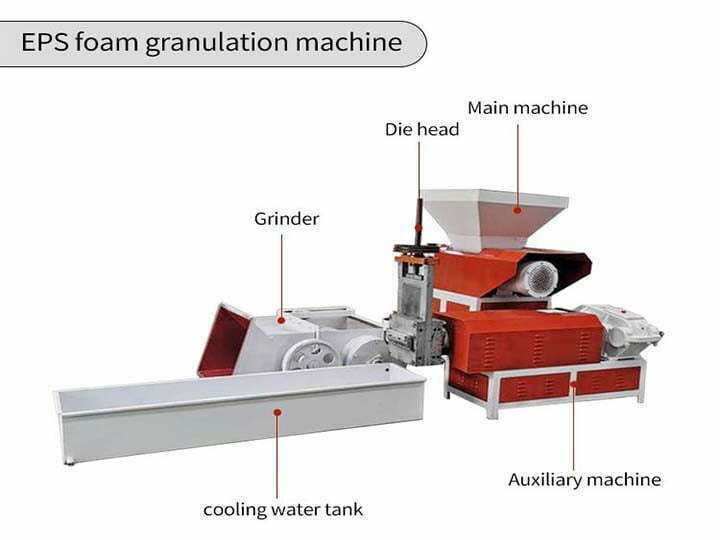

6、EPS泡沫颗粒机主要由破碎部分、主辅机、电动模具组成。

7、采用电动不间断换网模具,生产效率高。

8. EPS造粒机常与泡沫破碎机、水冷却箱、塑料颗粒切割机搭配使用,这些都常用于泡沫回收生产线。

EPS造粒机工作原理

EPS造粒机是通过对泡沫进行研磨、塑化、脱模、造粒等工序完成的。该机的主要功能是将泡沫破碎机破碎后的旧泡沫溶解,通过塑化、切条、切粒等过程制成小颗粒。以便于再生和再利用。

EPS造粒机视频

EPS造粒机参数

EPS造粒机的型号是根据螺杆轴的不同直径而定的。对于特定需求,我们还提供定制服务。

| 模型 | 规格 |

| 型号: 220+150

|

带破碎机的制粒机

功率:15kw+5.5kw 产能:150-200kg/h 双齿轮减速机 |

| 型号: 270+150

|

带破碎机的制粒机

功率:18.5kw+5.5kw 产能:200-250kg/h 双齿轮减速机

|

| 型号: 320+180

|

带破碎机的制粒机

功率:18.5kw+11kw 产能:250-300kg/h 双齿轮减速机 |

| 型号: 350+180

|

带破碎机的制粒机

产能:250-300kg/h 双齿轮减速机 |

相关机器

- 泡沫破碎机

- 水煮槽

水冷却箱 另一种泡沫造粒机