塑料造粒机也称为塑料颗粒制造机。它是用于熔融挤出废PP(聚乙烯)或PE(聚丙烯)颗粒以制造塑料颗粒的设备。造粒机的主机是挤出机,包括挤出系统、传动系统以及加热和冷却系统。破碎、清洁和干燥的塑料可以直接放入挤出机。然后,挤出的塑料条通常需要在冷却罐中冷却,并通过切粒机切割成颗粒。塑料薄膜造粒机是塑料回收厂的重要组成部分。它有利于大力发展再生资源,变废为宝。

工作视频

回收造粒机适用物料

塑料颗粒制造机的设计使其能够有效地将各种废料加工成颗粒。对于废塑料,我们将其分为消费后塑料和工业后塑料,这两种塑料都可以在我们的回收机器中进行处理。

后工业回收材料:为了节省原材料成本并实现循环经济,许多塑料生产商(例如塑料袋制造商)回收其边角料,然后继续将其生产的颗粒加工成塑料制品。这些后工业塑料包括 HDPE/LDPE 袋边料、卷膜、有缺陷的薄膜和袋产品、印刷拉链袋、有缺陷的 HDPE PVC 管、PP/HDPE/LDPE 回收料、HDPE 软/硬灌溉管等。

消费后回收材料:所有用过和废弃的塑料制品,如废旧塑料瓶、塑料袋、废弃仪表、汽车零部件、食品容器、化学品桶、塑料托盘、PP绳、塑料块、塑料桶、化妆品管、气泡膜、层压/多层薄膜、软包装材料等。

塑料造粒机出售

作为塑料颗粒生产线的主机,该设备适用于多种材料的造粒。处理不同材料的造粒机的外观相似但不相同。其内部组件需要根据具体材料进行调整,例如内螺杆直径、螺杆与料筒壁之间的距离以及螺杆长度。

因此,一台调整后的机器对应一种材料。调整后的设备更适合您原料的特性。因此,您可以联系我们,告诉我们您想要造粒的材料,以获取更详细的信息。此外,我们还支持根据您的具体回收要求定制服务。

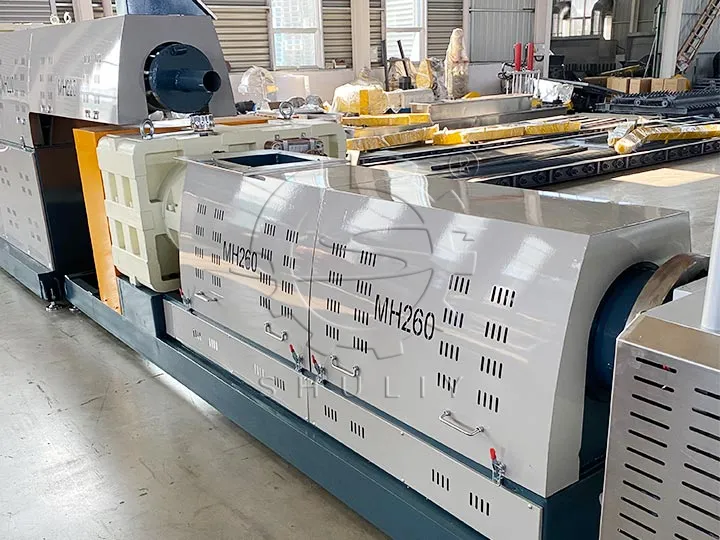

工厂机器展示场景

塑料造粒设备的特点和优点

- 设计独特、性能优良、噪音低、运行稳定、操作简单

- 工艺简单,技术先进,适用于各种废塑料

- 螺杆、机筒耐磨、耐用、产量高。

- 塑料造粒机每天可处理废塑料2-30吨。

- 主辅机一体化,安装简单,占地面积小,性价比高。

- 采用高压摩擦不间断加热,多功能加热方式,配备恒温系统

- 无需连续加热,减少能耗30-40%。

- 自动化程度高,人工干预少

- 可提供定制服务。

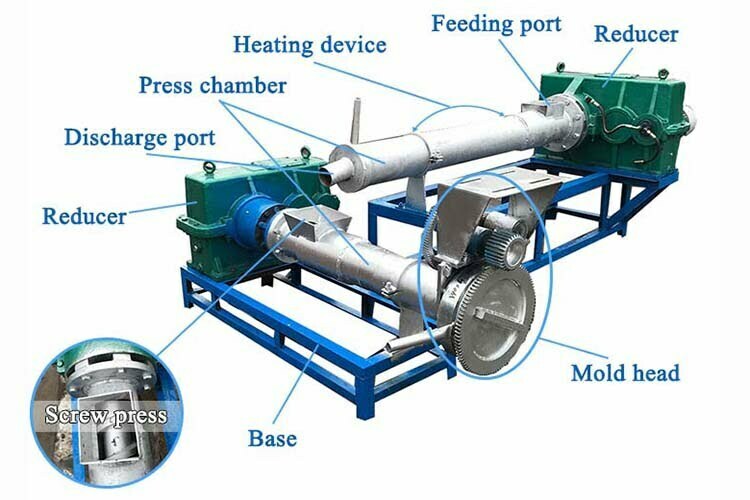

机器结构

塑料造粒机结构由减速机、加料口、加热装置、压榨室、出料口、螺旋压榨机、模头、底座等部分组成。

减速机是硬齿面减速机。作为塑料挤出机的重要组成部分,其质量至关重要。目前市场上普通减速机的质量排名为:老式蜗轮减速机 < 普通减速机 < 半硬齿面减速机 < 硬齿面减速机。

塑料挤出主要有两种类型的模头:电动模头和液压模头。液压模头的过滤网可以在不停机的情况下更换。对于含杂质较多的材料,液压式更合适。但成本也更高。塑料造粒机的型号主要根据螺杆直径划分。螺杆采用45#钢、40CR、38CRSI制造。塑料造粒设备的型号主要根据螺杆压力的直径划分。可根据其塑料加工特性提供镀铬、氮化等工艺的定制服务。

LDPE/HDPE造粒机加热系统

塑料挤出机的加热方式分为铸铝加热圈、石英管加热圈、陶瓷加热圈、电磁加热圈。其中,加热效果最好的是电磁加热。铸铝加热圈加热需要30-40分钟,电磁加热圈需要15-20分钟。电磁加热可以快速升高温度。并且恒温效果好,运行稳定。但它不适合加工泡沫材料。加热方式应根据原料和最终产品的颜色来考虑。

塑料造粒机的工作原理

- 打开HDPE/PP/PVC造粒机。检查机器是否有异常声音或振动。如果没有,请将其投入使用。

- 注意对塑料造粒机进行预热,使塑料熔化。如果温度太高,熔化的塑料会变黑。而低温则不能熔化塑料。

- 最好配备自动喂料机将塑料碎片喂入塑料造粒设备,因为塑料薄膜材料很轻,不易喂料。

- 将塑料薄膜碎片熔化并压入主机,然后随螺杆推入辅机。最后,熔化的材料将以塑料条的形式从辅助发动机中挤出。

- 在模头下方放置冷却槽,使热塑条在槽内冷却并成型。

塑料造粒机设备使用时要注意什么?

- 机器内部不应有金属残留物或细沙。请勿在进料口周围放置金属物品或其他物品,以免落入机器中,以免损坏塑料颗粒机,造成堵塞或破坏。

- 操作人员最好接受有关如何操作造粒机的实际培训。此外,还应了解设备的结构和操作流程。

- 控制冷却水箱的水温。因为如果温度太低,塑料条就会断裂。虽然高温不能使塑料条冷却并良好成型,并且条可能会粘住。

- 熔化的塑料在进入塑料颗粒切割机之前应均匀地挤出成条。不均匀的条带可能会损坏塑料颗粒切割机。如果挤出的条材很薄或断裂,模头的孔可能会被杂质堵塞。所以需要更换过滤网。

HDPE造粒机参数

| 类型 | 105 | 125 | 135 | 150 | 180 | 200 | 220 |

| 螺杆直径 | 105毫米 | 125毫米 | 135毫米 | 150毫米 | 180毫米 | 200毫米 | 220毫米 |

| 主轴转速 | 50-70/分钟 | 50-70/分钟 | 40-50/分钟 | 40-50/分钟 | 40-50/分钟 | 40-50/分钟 | 40-50/分钟 |

| 主电机功率 | 18.5千瓦 | 30千瓦 | 37千瓦 | 37千瓦 | 55千瓦 | 75千瓦 | 90千瓦 |

| 减速机(硬齿面) | 200 | 225 | 250 | 250 | 280 | 315 | 330 |

| 重量 | 1.3T | 1.8T | 2T | 2T | 2.2T | 2.8T | 3.2T |

| 尺寸 | 2.4*0.7*0.7 | 2.6*0.7*0.7 | 2.8*0.7*0.7 | 3.0*0.7*0.8 | 3.2*0.7*0.8 | 3.5*1*1 | 3.8*1.2*1 |

| 输出 | 150公斤/小时 | 180公斤/小时 | 200公斤/小时 | 300公斤/小时 | 350公斤/小时 | 380公斤/小时 | 420公斤/小时 |

我们有 7 种型号的造粒机供您选择。这7台机器最大的区别就是产量。产量分别为150kg/h、180kg/h、200kg/h、300kg/h、350kg/h、380kg/h和420kg/h。同样,不同的产量对应不同的价格。如果您有大型的塑料回收厂,我们建议您购买380kg/h或420kg/h的机器。我们还将给您最优惠的价格。其次,您需要考虑您的厂房面积和机器尺寸。正如您所看到的,更大的产量意味着更大的尺寸。例如,产量150kg/h的机器尺寸为2.4*0.7*0.7,而产量420kg/h的机器尺寸为3.8*102*1。如果您的厂房面积太小,它不适合超大机器,或者您可以调整工厂的大小。