Mashine ya kukandamiza tairi taka ya Shuliy inabonyeza tairi kubwa kuwa mabalo yenye msongamano. Inapatikana kwa modeli za mlalo na wima, mashine hii ya hidroliki hushughulikia hadi mabalo 5 kwa saa, kila moja ikikadiria kilo 1200. Inapunguza nafasi ya kuhifadhia, inarahisisha usafirishaji, na kusaidia biashara za kuchakata kuongeza faida.

Kutoka kwa Taka Isiyo na Thamani hadi Bidhaa Yenye Thamani

Mabadiliko ambayo mashine yetu ya kukandamiza tairi taka hufanya ni rahisi lakini ya kina. Inachukua malighafi yenye matatizo na kuibadilisha kuwa bidhaa inayohitajika.

- Malighafi: Aina zote za matairi ya takataka, ikiwa ni pamoja na matairi ya gari, matairi ya lori, matairi ya basi, na matairi ya kilimo. Kwa matairi makubwa ya OTR, usindikaji wa awali kwa Mashine ya kukata matairi inashauriwa kabla ya kuunganisha.

- Bidhaa Iliyokamilika: Magunia ya matairi yaliyo na umbo thabiti, yaliyo na kamba nzito na zilizoshikiliwa kwa nguvu. Kila guni lina uzito wa takriban kg 1200, na kufanya iwe rahisi kwa ajili ya kuweka na usafirishaji wa ufanisi.

Falsafa ya Uhandisi na Ubunifu wa Mashine Yetu ya Kukandamiza Tairi Taka

Mashine yetu ya kukandamiza tairi imejengwa kwa misingi ya uimara, nguvu, na ufanisi wa uendeshaji.

- Uadilifu wa Muundo: Muundo mkuu umejengwa kutoka kwa sahani za chuma zilizoboreshwa na boriti za muundo. Welds zote zimepumzishwa kwa msongo ili kuhimili mzigo mkubwa wa mzunguko unaoambatana na kusongesha mpira wa gundi wa chuma.

- Mfumo wa Nguvu wa Hydraulics: Kwenye msingi ni mfumo wa hydraulic wa tani 200. Mfano wa mwelekeo wa mwelekeo unatumia injini ya 45kw kuendesha pampu za shinikizo la juu, kuhakikisha nguvu na kasi ya kutosha kushinda athari ya kumbukumbu ya nyenzo na kufanikisha msongamano mkubwa wa magunia.

- Mtiririko wa Nyenzo na Ufanisi: Mfano wa mwelekeo wa usawa unajumuisha conveyor ya kuingiza kiotomatiki ya 5.5kw na mlango wa kuinua, kuunda mtiririko wa nyenzo unaoendelea na wenye ufanisi unaopunguza nyakati za mzunguko na kupunguza utegemezi wa operator.

- Mfumo wa Udhibiti: Mfumo wa PLC (Programmable Logic Controller) wa kati unasimamia kazi za mashine, kutoa mizunguko ya kiotomatiki ya kuaminika na interlocks muhimu za usalama kwa ulinzi wa operator.

Vipimo vya Kiufundi: Ulinganisho Sambamba

Tunatoa mifano miwili tofauti ili kukidhi mahitaji mbalimbali ya uendeshaji kulingana na kiwango, nafasi, na uwekezaji wa mtaji. Ili kukusaidia kufanya uamuzi bora kwa uendeshaji wako, hapa kuna kulinganisha moja kwa moja kwa mifano yetu miwili ya viwandani ya mashine ya kukandamiza tairi. Tofauti kuu zipo kwenye kiwango cha otomatiki, uwezo wa uzalishaji, na uwekezaji wa awali.

| Kipengele | Mashine ya kukandamiza tairi taka ya mlalo | Mashine ya Kukandamiza Tairi ya Wima |

| Bora kwa | Uendeshaji wa Kiasi Kikubwa, Ulio otomatiki | Yadi Ndogo, Anzishaji Wenye Bajeti Ndogo |

| Uwezo | mabalo 5 kwa saa | mabalo 3-4 kwa saa |

| Kiwango cha Otomatiki | Mlisho wa Otomatiki kwa Mkanda | Kupakia na Kufanya kazi kwa Mikono |

| Nguvu Kuu / ya Motor | 45 kW | 22kW |

| Ukubwa wa Bale | 125*125*170 cm(Inaweza kubadilishwa) | 150*100*120 cm |

| Udhamini | mwaka 1 bure | mwaka 1 bure |

- Ikiwa unatafuta ufanisi wa juu na automatisering wakati wa kushughulikia uzalishaji mkubwa, mashine ya kuunganisha kwa mwelekeo wa mwelekeo ni uwekezaji bora wa muda mrefu.

- Ikiwa una nafasi ndogo au unataka kuingia sokoni kwa gharama za awali ndogo huku ukipata uwezo wa shinikizo lenye nguvu, baler ya matairi ya mstatili inatoa thamani isiyolinganishwa.

Mashine ya Kukandamiza Tairi Inafanyaje Kazi?

Mchakato wa kufanya kazi wa mashine ya kukandamiza tairi taka umeundwa kuwa rahisi na wenye ufanisi, kubadilisha kazi tata kuwa mtiririko ulio rahisishwa.

- Kufunga: Tairi taka huwekwa kwenye chumba cha kukandamiza. Chumba kimeundwa kushikilia tairi kadhaa kwa wakati mmoja.

- Kukandamiza: Mashine ya kukandamiza tairi ya hidroliki hutumia shinikizo kubwa, ikisukuma silinda chini ili kukandamiza tairi tabaka kwa tabaka. Hii huzuia kurudi nyuma na kuhakikisha usalama wa kazi.

- Umbo: Katika shinikizo lililowekwa, tairi huunda block yenye msongamano na umbo la kawaida. Ukubwa mdogo unarahisisha kushughulikia, kuhifadhi, na kusafirisha.

- Kufunga kwa kamba: Bale iliyobanwa inafungwa kwa waya wa chuma au mikanda ya plastiki. Hii huhakikisha block ya tairi inabaki salama na imara.

- Kutokwa: Hatimaye, mashine ya kukandamiza tairi taka inasukuma au kugeuza bale iliyomalizika, tayari kwa kuondolewa kwa forklift au kwa mikono.

Matumizi: Kufungua Thamani ya Soko ya Mabalo ya Tairi

Mabalo ya tairi yaliyobanwa si taka; ni bidhaa yenye thamani yenye njia mbili kuu za soko: Urejeshaji Nguvu na Urejeshaji Vifaa. Hii inahakikisha una soko la uhakika na tofauti kwa uzalishaji wako.

Urejeshaji Nguvu

Mafuta Yanayotokana na Tairi (TDF): Mabalo ndiyo chanzo kikuu cha mafuta kwa viwanda vya saruji, mitambo ya karatasi na karatasi, na boila za viwandani kutokana na thamani yake kubwa ya kalori na ufanisi wa gharama ikilinganishwa na makaa.

Urejeshaji Vifaa

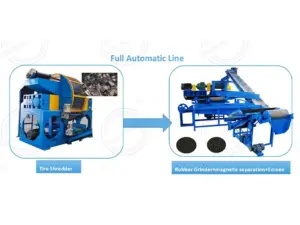

- Malighali kwa ajili ya Utengenezaji wa Maji wa Mpira: Jukumu kuu la kuunganisha hapa ni kupunguza sana gharama za usafirishaji hadi kiwanda cha usindikaji wa kati. Kiwanda, magunia yanachukuliwa na kuondolewa kamba na matairi yanapewa ndani ya mstari kamili wa urejelezaji wa matairi kubadilishwa kuwa maganda ya mpira wa thamani kubwa, unga, na chuma kilichotenganishwa.

- Matumizi katika Uhandisi wa Kiraia: Mabalo pia hutumika moja kwa moja katika miradi kama nyenzo ya kujaza yenye uzito mwepesi, inayopenya, na kupunguza mtetemo kwa barabara za juu, kuta za kujizuia, na ujenzi wa dampo.