Mashine ya kusaga pellet ya EPS ni mashine maalum ya kuchakata tena kwa ajili ya kusagwa na kusaga takataka ya styrofoam, au polystyrene inayoweza kupanuliwa (EPS). Pelletizer ya EPS ina muundo unaofaa, kiwango cha juu cha otomatiki, teknolojia ya hali ya juu isiyo na uchafuzi wa mazingira. Chembe za plastiki zinazozalishwa ni sare kwa ukubwa na mwangaza. Chembechembe zinazozalishwa hutumiwa sana, kama vile vifaa vya kuhami ukuta, vifaa vya ufungaji wa bidhaa, na vifaa vya msaidizi kwa baadhi ya bidhaa.

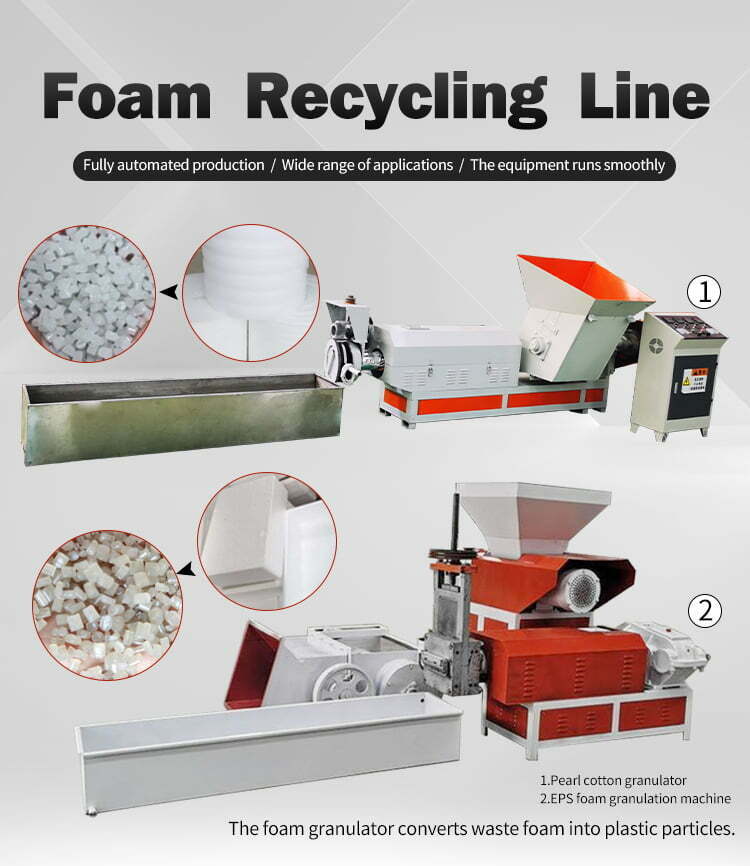

Siku hizi, kiasi cha polystyrene inayoweza kupanuliwa (EPS) inaongezeka kwa kasi. Plastiki hizi za povu za polystyrene ni nyepesi, ni nyingi, haziwezi kuzeeka, na ni ngumu kushika kutu, kwa hivyo zimekuwa shida kubwa katika utupaji wa takataka. Katika miaka ya hivi karibuni, kuchakata povu ya EPS imevutia umakini zaidi na zaidi, na urejeshaji wa polystyrene yenye povu ina matarajio mapana. Mashine za kutengeneza pelletizer za EPS mara nyingi hutumiwa katika mistari ya kuchakata plastiki na kuwa maarufu zaidi katika tasnia ya kuchakata tena. Kando na mashine ya chembechembe ya povu ya EPS, pia tunatoa granulators za pamba za EPE/Lulu.

Utumizi wa mashine ya EPS pelletizer

EPS foam granulation machine inatumika kuchakata styrofoam kutoka kwa masanduku ya takataka ya chakula, vifaa vya kaya, vifaa vya pakiti vya styrofoam kwa ajili ya ulinzi wa usafirishaji, na kadhalika ili iweze kubadilishwa kuwa mipira ya EPS inayoweza kurejelewa. foam ya plastiki iliyokasirishwa na EPS melt densifier pia inatumika. Plastiki hii iliyorejelewa inaweza kutumika kutengeneza vifaa mbalimbali vya insulation, vifaa vya kufungashia, vifaa vya kuchezea, na vifaa vya umeme, na kadhalika.

Manufaa bora zaidi ya EPS mashine ya kuweka pelletizing

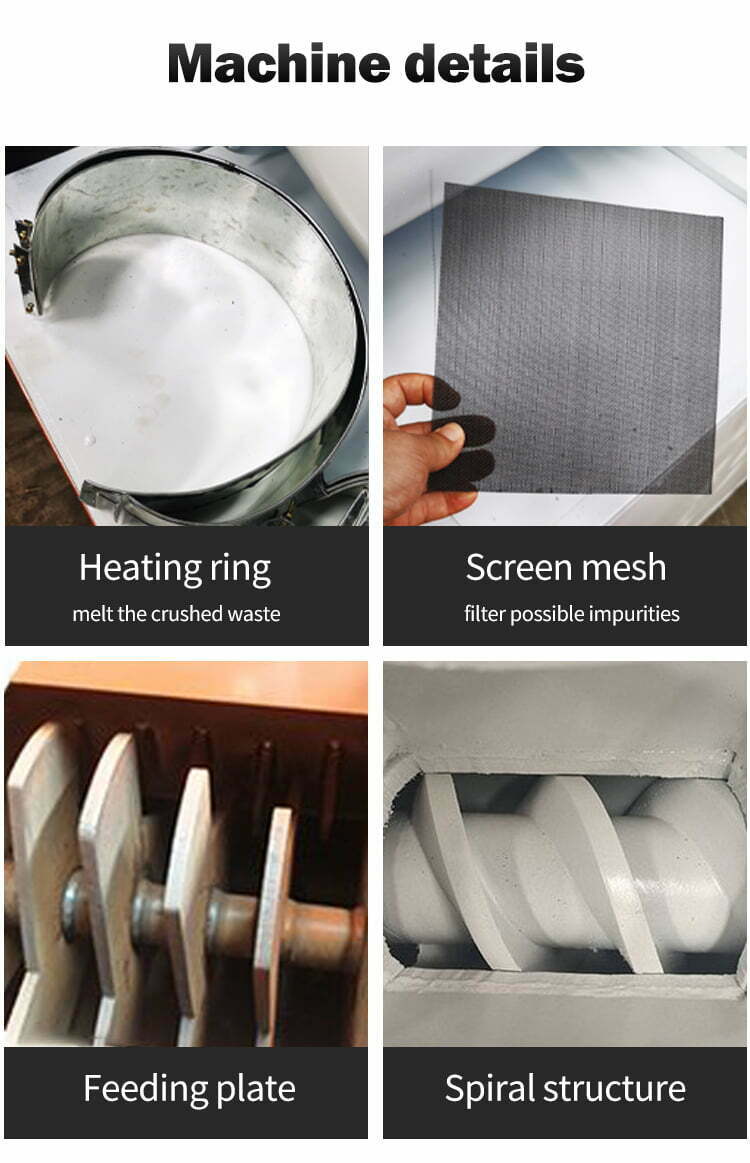

1. Vipu vya mashine kuu na vya ziada vinatengenezwa kwa chuma cha 45# kilichotiwa joto. Ina sifa nzuri za kina za mitambo.

2. Motor ina vifaa vya kupunguza gear mbili, ambazo hutambua operesheni imara na kuweka maisha ya huduma ya muda mrefu.

3. Granulator ya povu ya EPS inachukua pipa ya screw conical, ambayo ina kiwango cha juu cha kulisha na pato la juu.

4. Mashine kuu na za ziada hutumiwa pamoja kwa ajili ya kusaidia uzalishaji. Joto la kupokanzwa ni thabiti, muundo wa nyenzo za Masi huboreshwa kwa ufanisi, upenyezaji wa hewa huimarishwa, na ubora wa chembe unaboreshwa kwa kiasi kikubwa. Joto kuu la injini ni digrii 200 Celsius, na joto la injini ya msaidizi ni digrii 180 Celsius.

5. Kuna njia mbili za kupokanzwa kwa chaguo. sumakuumeme (muda wa kupokanzwa dakika 10-15), bomba la kupokanzwa umeme / pete ya kupokanzwa ya umeme (dakika 30-40)

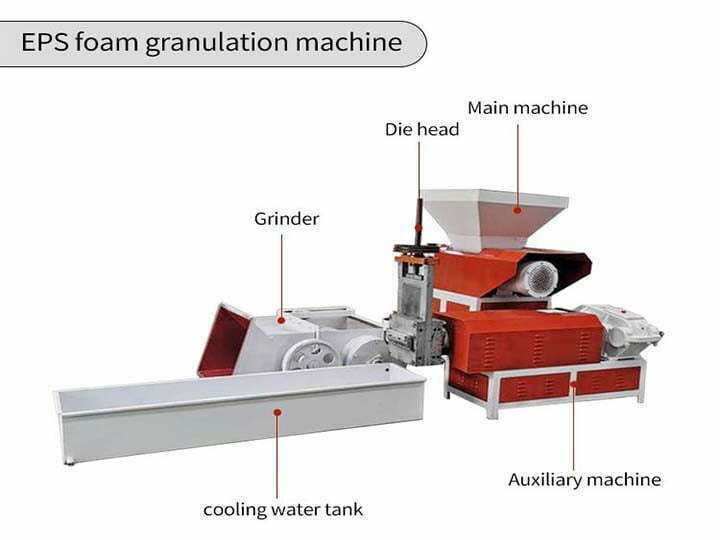

6. Mashine ya kutengeneza povu ya EPS hasa inajumuisha sehemu ya kusagwa, injini kuu na msaidizi, ukungu wa umeme.

7. Pitisha skrini ya umeme inayobadilisha ukungu bila usumbufu ili kufikia ufanisi wa juu wa uzalishaji.

8. Mashine ya kusaga nafaka ya EPS mara nyingi huunganishwa na kiponda povu, tanki la kupozea maji, na mashine ya kukata nafaka ya plastiki, ambayo mara nyingi hutumiwa katika mistari ya kuchakata povu.

Kanuni ya kazi ya EPS pelletizer

Mashine ya eps pelletizing inakamilishwa na mchakato wa kusaga, kuweka plastiki, kuvua na kusaga povu. Kazi kuu ya mashine hii ni kuyeyusha povu kuukuu baada ya kusagwa na kiponda povu, kutengeneza chembechembe ndogo kupitia mchakato wa kuweka plastiki, kukata vipande na kukata nafaka. ili kuwezesha kuzaliwa upya na kutumia tena.

Video ya mashine ya granulation ya EPS

Kigezo cha mashine ya EPS pelletizer

Mfano wa mashine ya pelletizing ya EPS inategemea kipenyo tofauti cha shimoni la screw. Kwa mahitaji maalum, pia tunatoa huduma maalum.

| Mfano | Vipimo |

| Mfano: 220+150

| Mashine ya kutengeneza pellet yenye crusher Nguvu:15kw+5.5kw Uwezo: 150-200kg / h Kipunguza gia mara mbili |

| Mfano: 270+150

| Mashine ya kutengeneza pellet yenye crusher Nguvu:18.5kw+5.5kw Uwezo: 200-250kg / h Kipunguza gia mara mbili

|

| Mfano: 320+180

| Mashine ya kutengeneza pellet yenye crusher Nguvu:18.5kw+11kw Uwezo: 250-300kg / h Kipunguza gia mara mbili |

| Mfano: 350+180

| Mashine ya kutengeneza pellet yenye crusher Uwezo: 250-300kg / h Kipunguza gia mara mbili |

Mashine zinazohusiana

- mashine ya kusaga povu

- tank ya kupikia maji

tank ya kupozea maji Aina nyingine ya mashine ya povu ya pelletizer