После того как шины были очищены и нарезаны на узкие резиновые секции, последним шагом перед измельчением или гранулированием является нарезка этих полос на более мелкие куски. Машина для нарезки шин Shuliy является надежным и прочным решением для этого критически важного этапа. Разработанная для переработки резинок, полос и толстых боковых стенок, наша машина для нарезки шин значительно повышает эффективность переработки и снижает нагрузку на последующие измельчители.

We offer two models to meet different capacity needs: the Standardized Tire Block Cutting Machine and the Updated Tire Block Cutter, both widely used in semi-automatic tire recycling lines.

Сырьевые материалы и конечные продукты резака для шинных блоков

Сырье:

-

Резиновые полосы от резака полос шин

-

Отработанных покрышек и толстых резинок

-

Обработанные боковые части от резака боковин шин

Конечные продукты:

-

Компактные резиновые куски, размеры которых оптимизированы для загрузки в измельчители шин, грануляторы или установки девулканизации

-

Типичные размеры блоков: 3×5×6 см (стандартная модель) или 5×5 см (обновленная модель)

Почему стоит выбрать нашу машину для резки шин?

-

Две модели для разных масштабов производства

-

Компактный выход блоков для эффективного измельчения

-

Прочная структура и стабильная производительность резки

-

Простая в использовании гидравлическая система управления

-

Совместим с различными резиновыми материалами, включая толстые протекторы и боковины

-

Бесшовно интегрируется в линии переработки шин с резаком для шинных полос и шинной дробилкой.

Параметры нашего резака для шин

Shuliy предлагает две мощные модели машин для резки резинок, предназначенные для нарезки резиновых протекторов и полос на компактные блоки. Независимо от того, управляете ли вы средним или крупным заводом по переработке отходов шин, наши машины могут эффективно удовлетворить ваши производственные потребности.

| Модель | Обычный резак для шинных блоков | Обновленный резак для шинных блоков |

|---|---|---|

| Мощность двигателя | 5.5 кВт – Стабильная работа для резки резины средней нагрузки | 18.5 кВт – Высокая мощность для тяжелых операций |

| Производственная мощность | 800 кг/ч – Подходит для легких и средних заводов | 1500 кг/ч – Для крупных линий переработки |

| Размер выходного блока | Куски резины 3 × 5 × 6 см | Резиновые блоки 5 × 5 см |

| Габариты машины (Д×Ш×В) | 1.0 × 0.8 × 1.4 м | 1.3 × 1.1 × 1.5 м |

| Масса | 800 кг | 1200 кг |

| Совместимость материалов | Резиновые полосы, протекторы шин, боковины | Тяжелые резиновые блоки, толстые протекторы |

| Метод резки | Гидравлическая система ножа с опусканием | Улучшенная система резки под высоким давлением |

Как работает резак для шин?

Работа гидравлического лезвия

Обе модели используют вертикальное гидравлическое режущее лезвие. Оператор кладет резиновые полосы плашмя на режущий стол, а затем активирует пресс для нарезки материала на однородные блоки.

Высокая сила резания

Обновленная версия оснащена более мощным двигателем (18,5 кВт), обеспечивающим более высокую силу для более твердых материалов и более высокую производительность.

Какой резак для резинок подходит вам?

-

Используйте стандартизированную модель, если вы работаете с небольшим или средним оборудованием для резки б/у шин с умеренными потребностями в производительности.

-

Выберите обновленный резак для шинных блоков для операций по переработке резины в больших объемах, где требуется более быстрая обработка и работа с более жесткими резиновыми материалами.

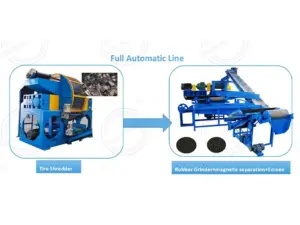

Обе машины разработаны для бесшовной работы с резателями для шин и интегрируются в полуавтоматическую линию переработки отработанных шин. Если у вас есть другие производственные потребности, мы также можем предложить вам индивидуальные машины для резки шин!