La machine de granulation de films plastiques est l'équipement principal de la ligne de recyclage du plastique. Elle peut transformer les déchets de films plastiques PP PE en granulés de plastique. Ces matières premières plastiques usagées comprennent les sacs de courses, les films d'emballage, les sacs poubelles, les sacs tissés, les sacs non tissés, les films agricoles, les conteneurs, les sacs liquides, etc. Par conséquent, notre machine de granulation de films plastiques a un large éventail d'applications. L'utilisation généralisée des granulateurs de films plastiques a efficacement réduit la pollution blanche mondiale et amélioré notre environnement de vie.

How is Plastic Film Recycled by Using the Plastic Film Pelletizing Machine?

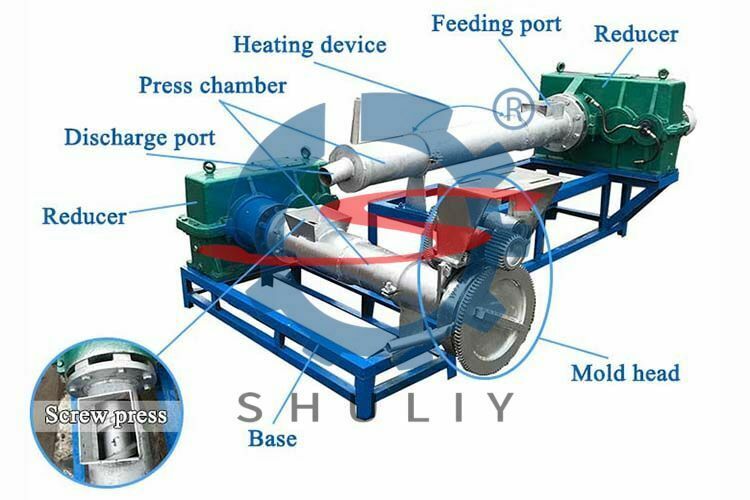

Plastic film pelletizing machine is composed of the main machine and auxiliary machine. The host machine can heat the plastic film into a paste. According to different power, we have 125, 150, and 180 plastic granulation equipment with different accessories. In addition, the heating mode of this machine is electromagnetic heating. Plastic granulator adopts automatic temperature control device. This means that compared with other brands of granulators, it consumes less power and has no pollution. Of course, the power and quantity can be selected according to the customer’s order.

Working Process of Plastic Granulation Equipment

Dried materials enter the plastic granulator machine from the feed inlet. The material melts under the heating of the heating ring. And the temperature of the heating ring around the plastic granulator can quickly reach more than 110 ℃, and then the material will melt under the heating of the heating ring. It is worth mentioning that the melting point of most plastic films is 85 to 110 ℃. So you don’t have to worry about the incomplete melting of materials. Then, the melted plastic film flows out of the outlet of the main engine and then enters the auxiliary engine. Under the extrusion of the auxiliary machine, it is extruded from the die of the machine head.

Paramètres de la machine pelletiseur

| Modèle | SL-125 | SL-150 | SL-180 |

| Screw diameter | 125mm | 150mm | 180mm |

| Main shaft speed | 50-70min | 40-60min | 40-50min |

| Main motor | 22+1.5kw | 30+1.5kw | 45kw |

| Capacité | 3T/day | 5T/day | 7T/day |

We have three different models of plastic granulation equipment, and the output is 3t / day, 5t / day, and 7T / day respectively. At the same time, the larger the output, the larger the size of the machine. You can choose machines that meet your needs. If you have any questions, please feel free to contact us.

Advantages of Plastic Film Pelletizing Machine

- Our high-performance plastic film recycling equipment can help provide better productivity and higher efficiency.

- Our machines are made of durable materials.

- Easy to install, operate and maintain.

- The high degree of automation.

- Low power consumption and no pollution.

- After being processed into particles by the plastic mill, waste plastics still have excellent comprehensive material properties. Because it can meet the technical requirements of film blowing, wire drawing, pipe drawing, injection molding, extrusion profile, and so on. It is the ideal equipment for plastic wrap recycling.

Application of This Plastic Recycling Machine

Notre machine de granulation de films plastiques est largement utilisée pour les sacs de courses, les films d'emballage, les sacs poubelles, les sacs tissés, les sacs non tissés, les films agricoles, les conteneurs, les sacs liquides, etc. Ainsi, elle peut également être utilisée comme machine de recyclage de sacs en plastique. Pour être honnête, la machine de granulation de plastique peut traiter de nombreuses matières premières plastiques différentes. Cependant, en raison des différents points de fusion et de la dureté des matières premières, l'effet final sera différent. Notre granulateur de plastique granule principalement des produits en plastique souple. Si votre matière plastique est souple, alors notre machine est votre équipement de recyclage de plastique idéal. Si vous avez d'autres problèmes de recyclage de plastique, veuillez nous contacter et nous vous répondrons à temps.