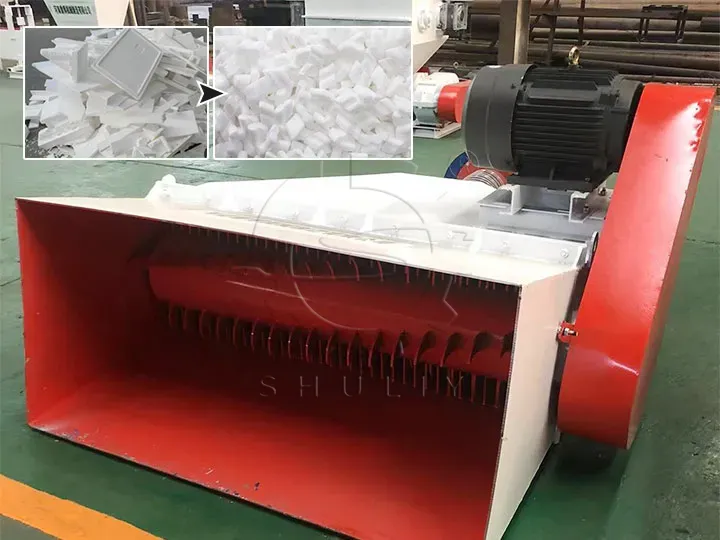

Styrofoam shredder machines, also known as polystyrene shredding machines, can efficiently crush EPS, EPE, EPP, and other foam raw materials. It has a capacity of 250-500kg/h and can be customized to satisfy all scales of styrofoam recycling factories. Whether you want post-consumer or in-plant EPS recycling, please read this article to discover what our foam crushing machine can do for you!

How Can Our Styrofoam Shredder Benefit You?

Key Features of the EPS Foam Shredder

- Wide Application: Our EPS crusher machine can be widely used in styrofoam recycling stations, EPS recycling or processing factories, the packaging industry, construction sites, and other scenes to help deal with a variety of foam raw materials and facilitate the transportation and processing of plastic foams.

- High Efficiency: The capacity of foam crushers ranges from 250 to 500kg/h, and there are a variety of models to choose from, allowing for quick, efficient crushing.

- Easy Operation: The feed inlet is designed horizontally, flush with the ground, which makes it easy for staff to feed materials effortlessly. The crushed foam blocks are then transferred to the hopper. The whole process is highly automated.

- High Quality Of Finished Products: The shape and size of the crushed EPS/EPE blocks are uniform, and the surface is complete without dust. No metal and other impurities mixed in, suitable for subsequent hot melt, pelletizing, and other steps.

- Energy Saving And Environmental Protection: The styrofoam shredder machine adopts a noise reduction and vibration damping design, and the pipeline connects each device to avoid polluting the air quality. Meanwhile, it is equipped with a high-efficiency motor and sharp blades to avoid ineffective energy consumption and reduce power waste.

What Value Can You Get?

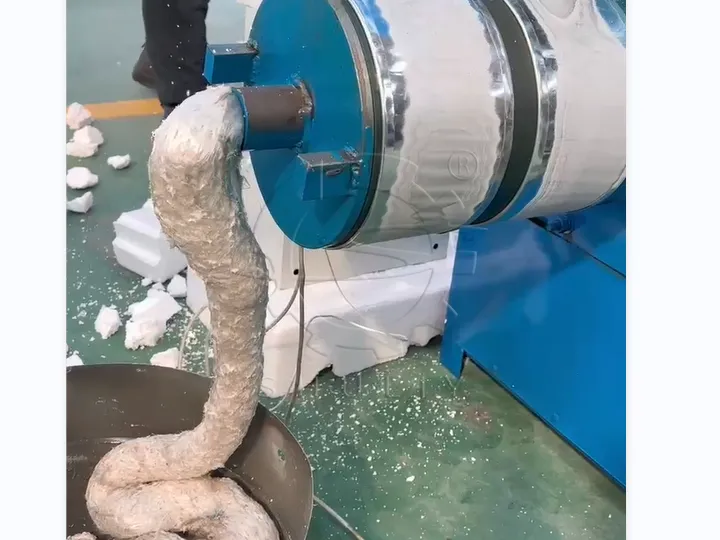

- Can be used with a styrofoam melter machine to melt and compress the expanded polystyrene to obtain high-density foam ingots.

- Crushing plastic foams into uniform chunks to improve EPS/EPE pelletizing efficiency.

- Reduces the amount of foam that goes directly to landfill or incineration, which is environmentally friendly.

Raw Materials And End Products of the Styrofoam Shredder Machine

Raw Materials:

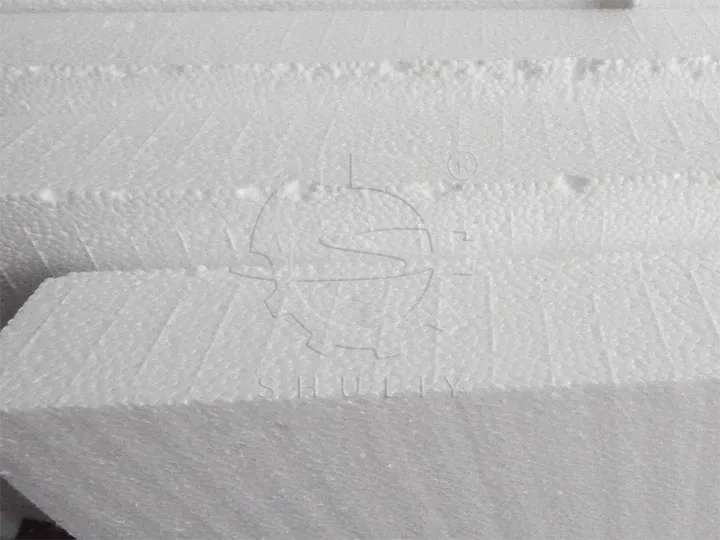

EFFICIENT Polystyrene Crusher is commonly used to process EPS, EPE, and other foam materials, commonly including styrofoam boxes, packing foam sheets, polystyrene insulation, EPS lunch boxes, XPS building insulation boards, yoga mats, sofa filling, etc. The EPS foam crusher can be used for all sizes of foam recycling plants and is the first machine in a polystyrene recycling line.

Final Products:

The shredded EPS foam blocks are usually in the form of uniformly sized foam fragments, with the material intact and uncontaminated, and the overall volumes are reduced, which facilitates subsequent recycling.

Basic Technical Data of The Foam Crusher

Here are the parameters of some hot models for reference. We offer various types and custom styrofoam shredders to meet your production needs. Please send us your production situation and we will recommend the most suitable styrofoam shredding machine for you.

- TYPE: SL-800/ SL-1000/ SL-1200/ SL-1500

- POWER(kW): 5.5/ 5.5/ 7.5/ 11

- CAPACITY(kg/h): 250-300/ 300-350/ 400-450/ 450-500

- INPUT SIZE(cm): 800*600/ 1000*600/ 1200*600/ 1500*600

How Does The EPS Foam Crusher Work?

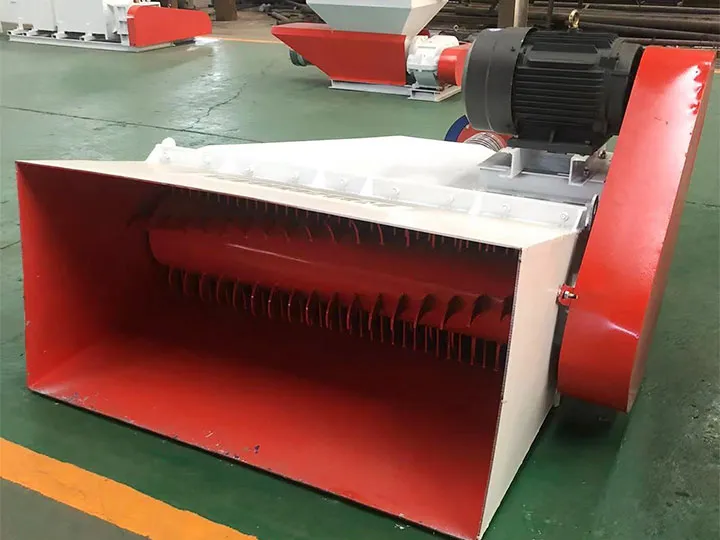

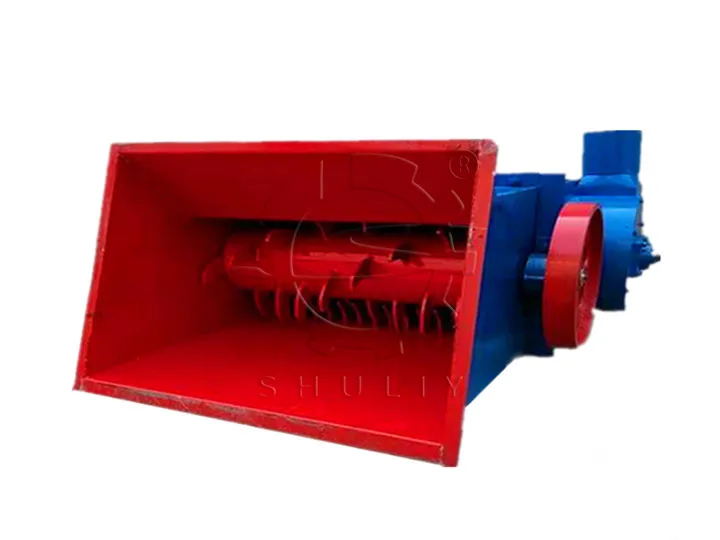

The styrofoam shredder machine consists of a feed inlet, a crushing chamber, blades, screens, and a base.

Waste plastic foams enter the shredding chamber through the feed inlet and the high-quality stainless steel blades rotate to shred the foam to the pre-set size. Then the EPS foam pieces that meet the requirements pass through the screen and are transferred to the hopper of the styrofoam melter for the next recycling process.

خدماتنا

- Answering your recycling questions, sharing success cases and recommending the most suitable model for your design;

- Lead time is approximately two weeks after order placement, and we will send you regular production progress updates;

- Technical support, on-site installation and one year warranty.

Summary

As the first step in the styrofoam recycling, plastic foam crushing process affects the efficiency of the entire polystyrene recycling. Selecting the right high-quality styrofoam shredder can help to efficiently reduce the volume of foam, facilitate subsequent processing and improve recycling efficiency. If you are interested, please contact us, we will make recommendations for you!