Ujerumani daima imekuwa ikijulikana kwa kiwango chake cha juu cha ulinzi wa mazingira na uhamasishaji hai wa kuchakata rasilimali. Ili kuitikia wito wa serikali na kuboresha ufanisi wa kuchakata tena, kiwanda cha kuchakata povu nchini Ujerumani kilianza kutafuta suluhu za ukataji wa styrofoam ambazo ni rafiki kwa mazingira na kuokoa nishati. Hivi majuzi, walikamilisha ushirikiano wenye mafanikio wa kuvuka mpaka na sisi.

Mahitaji ya Wateja wa Ujerumani

Mteja wa Ujerumani anahusika zaidi katika kuchakata tena styrofoam kwa tasnia ya vifungashio. Marundo makubwa ya povu ya plastiki yalikuwa yakichukua nafasi nyingi za kuhifadhi. Gharama za usafiri, uhifadhi na utupaji bidhaa zilikuwa zikiongezeka. Wakati huo huo, mashine ya awali ya mteja ya kuponda EPS ilikuwa inazeeka na ilikuwa na utendakazi na uwezo mdogo, ambayo ilikuwa rahisi kukwama na kuziba na haikuweza kukabiliana na kiwango cha sasa cha uzalishaji kinachopanuka.

Kando na hilo, kwa sababu ya mahitaji madhubuti ya uzalishaji wa kijani kibichi nchini Ujerumani, mteja wetu anatarajia kununua mashine ya kusaga ya EPS yenye uwezo mkubwa yenye ufanisi wa hali ya juu na uimara, kuokoa nishati na ulinzi wa mazingira.

Suluhisho la Shuliy Kwa Kupasua Styrofoam

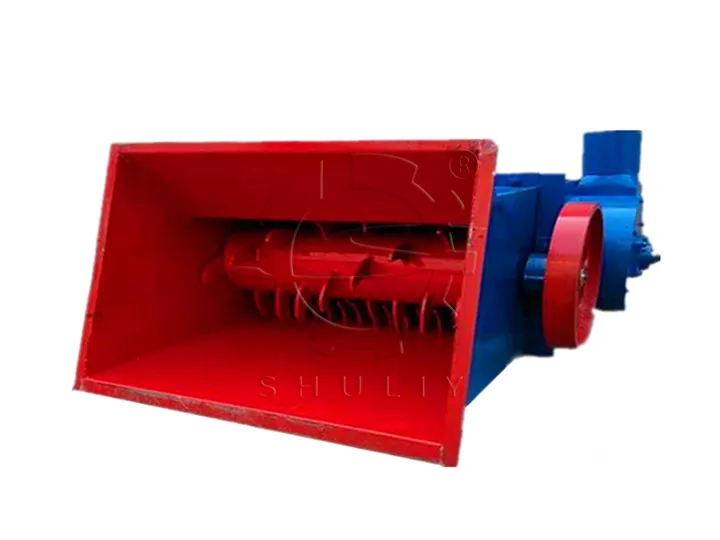

Baada ya kuelewa mahitaji ya mteja, meneja wetu wa mauzo alipendekeza kiponda povu cha SL-1000 kulingana na hali ya uzalishaji wa mteja: suluhisho la ubora wa juu la kusagwa na uwezo wa takriban 350 kg / h. Baada ya onyesho la video na ziara ya kiwanda, mteja alionyesha kupendezwa sana na imani katika mashine hii ya kupasua styrofoam. Baada ya kujadili na kukamilisha baadhi ya maelezo mahususi, ushirikiano huu wa kuvuka mpaka umeanza.

Kwa nini Chagua Mashine Yetu ya Kusaga EPS?

- Mchoro wa uingizaji wa malisho uliopanuliwa hufanya iwe rahisi kuponda vipande vikubwa vya plastiki, na si rahisi jam na kuziba;

- Vile vinatengenezwa kwa chuma cha pua cha hali ya juu, kupambana na kutu kali na kudumu;

- Mfumo wa kuchuja vumbi uliojengwa ndani, hupunguza utoaji wa kaboni, na kukidhi mahitaji ya mazingira;

- Kiwango cha juu cha otomatiki na operesheni rahisi.

Ufuatiliaji Maendeleo ya Ufungaji

Baada ya kuthibitisha ununuzi, timu ya Shuliy ilipanga haraka uzalishaji husika, na baada ya kuwasiliana na mteja kwa uthibitisho, ilifanya marekebisho fulani ya desturi kwa crusher ya EPS, ikiwa ni pamoja na nyenzo za vile, nk.

Katika muda wa wiki mbili hivi, tulifaulu kuwasilisha kifaa cha kusaga povu nchini Ujerumani kupitia ugavi wa kimataifa. Wahandisi walifika kiwandani hapo kusaidia ufungaji na kutoa maelezo ya kitaalamu.

Maoni Chanya kutoka kwa Mteja Wetu wa Ujerumani

Mashine ya kusaga povu ya EPS imekuwa ikitumika kwa muda. Tumepokea maoni chanya kutoka kwa mteja wetu wa Ujerumani na tunafuraha kuweza kumsaidia mteja kufikia urejeleaji wa povu kwa ufanisi na kukuza uhifadhi wa mazingira.

Mteja anasema: "Kikanda kipya cha EPS hufanya kazi vizuri sana na ufanisi wetu wa kuchakata EPS umeboreshwa sana!". Wameona ongezeko la karibu 40% katika ufanisi wa kuchakata styrofoam na punguzo kubwa la gharama za kuhifadhi na usafirishaji. Hongera kwa mafanikio yao katika kuboresha biashara iliyopanuliwa ya kuchakata tena polystyrene kupitia matumizi ya mashine ya kusaga styrofoam huku ikikidhi mahitaji ya mazingira!

Hitimisho

Shuliy daima imekuwa ikijulikana kwa mashine zake za ubora wa juu na huduma ya adabu. Tumejitolea kusaidia visafishaji vya plastiki kote ulimwenguni kuboresha ufanisi wao wa kuchakata na kuchangia katika uchumi wa kijani kibichi!

Ushirikiano huu wenye mafanikio na mteja wa Ujerumani unaashiria mafanikio mengine kwetu. Ikiwa pia una matatizo na kuchakata povu, tafadhali tutumie mahitaji yako ya uzalishaji na tutakupa mapendekezo yanayofaa!