مع تطور الزراعة والتعدين وغيرها من الصناعات، زاد عدد إطارات الطرق غير المستخدمة (OTR) الم discarded بشكل كبير. على الرغم من أن إطارات التعدين المهملة لها قيمة إعادة تدوير عالية، إلا أنه من الصعب معالجتها مباشرة بسبب حجمها الكبير وبنيتها القوية. يمكن لآلات إعادة تدوير إطارات التعدين من شولي معالجة إطارات OTR العملاقة التي يزيد قطرها عن 1400 مم للحصول على مسحوق مطاطي قابل للتعديل بأحجام تتراوح من 10 إلى 40 شبكة، وإطارات فولاذية، وألياف نايلون لإعادة الاستخدام.

دور آلات إعادة تدوير إطارات التعدين من شولي

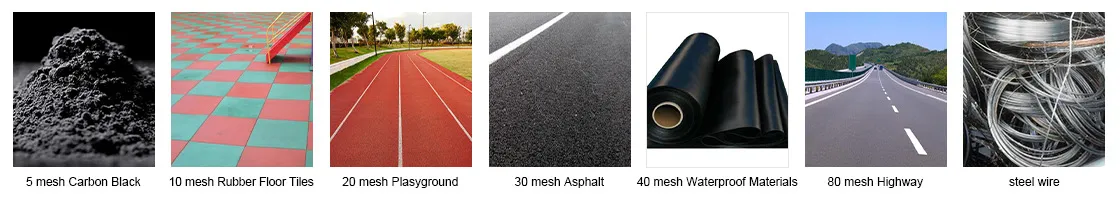

نظام إعادة تدوير إطارات التعدين هذا مناسب لجميع الإطارات الكبيرة بقطر يزيد عن 1400 مم، بما في ذلك إطارات التعدين، وإطارات آلات التحريك، وإطارات اللودرات، وغيرها. من خلال عملية التفكيك، والسحق، والطحن، والفرز، يتم الحصول على مسحوق مطاطي ناعم وموحد. تُستخدم هذه المساحيق على نطاق واسع في إعادة تصنيع تعديلات الأسفلت، والإطارات المعاد تدويرها، وسجاد المطاط، وغيرها من المنتجات المطاطية. يمكن ضبط نعومة مسحوق المطاط من 10 إلى 40 شبكة حسب الطلب.

بالإضافة إلى ذلك، يتم فصل أسلاك الصلب والألياف بشكل فعال خلال عملية إنتاج مسحوق الإطارات. يمكن استخدام هذه المواد كمواد خام لإنتاج الصلب وكوقود بديل، على التوالي. وهذا يعزز بشكل كبير معدل استخدام الموارد والقيمة الاقتصادية للإطارات المستعملة من نوع OTR.

مزايا معدات إعادة تدوير إطارات التعدين لدينا

- مع قابلية التكيف العالية والتطبيق الواسع، فهي مناسبة لجميع إطارات OTR بقطر أكبر من 1400 مم.

- تم بناء الآلة بالكامل وفقًا لمعايير الصناعة الثقيلة بهيكل متين، ومواد مقاومة للتآكل، وسعة تحميل قوية، وكفاءة تشغيل عالية.

- يمكن ضبط نعومة مسحوق المطاط من 10 إلى 40 شبكة لتلبية متطلبات الإنتاج المختلفة.

- تفصل بكفاءة عالية بين سلك الفولاذ والشوائب الليفية، ويكون مسحوق المطاط نقيًا بنسبة 99% أو أكثر.

- تتميز باستهلاك منخفض للطاقة وتتوافق مع معايير حماية البيئة وتوفير الطاقة.

خطان لإنتاج الطاقة المطاطية أوتوماتيكيان بالكامل

لتلبية احتياجات إعادة تدوير إطارات OTR ذات الأحجام المختلفة بشكل كامل، تقدم شولي طريقتين للمعالجة: "سحب الأسلاك - التقطيع - السحق - الطحن" تُستخدم للإطارات متوسطة الحجم (1400-4000 مم)، بينما تُستخدم "التفكيك - التقطيع - الطحن" للإطارات الكاملة الكبيرة (≥2100 مم). هناك أيضًا خيارات مرنة متاحة لتلبية احتياجات الإنتاج المختلفة.

خط إعادة تدوير إطارات OTR للإطارات من 1400-4000 مم

آلات إعادة تدوير إطارات التعدين المعنية:

آلة إزالة الجوانب لإطارات OTR، آلة قطع إطارات OTR، كسارة إطارات المطاط، محطم الإطارات وفاصل مغناطيسي

سير العمل:

- تقوم آلة سحب إطارات OTR بإزالة الحواف الجانبية بكفاءة باستخدام نظام هيدروليكي قوي وجهاز قبضة.

- يتم تقسيم إطار المطاط، بعد إزالة حوافه، إلى قطع سهلة التقطيع بواسطة آلة قطع.

- تقوم كسارة الإطارات بتقطيع الإطارات بقوة إلى قطع صغيرة ومتجانسة بحجم 50-100 مم باستخدام قاطع دوار عالي السرعة.

- طحن الأسطوانات المزدوجة وتطبيق أجهزة الفرز متعددة الطبقات والفصل المغناطيسي، ينتج مسحوق المطاط وفقًا للحجم المحدد، مما يحقق فرزًا دقيقًا.

- يفصل جهاز فصل الألياف بفعالية الشوائب الليفية باستخدام فرز الهواء.

معدات إعادة تدوير إطارات OTR المعنية: آلة تفكيك إطارات OTR، فاصل الأسلاك الفولاذية لإطارات OTR، آلة تمزيق الإطارات، آلة طحن الإطارات والفصل المغناطيسي.

سير العمل:

- تقوم آلة تفكيك الإطارات الكبيرة بتفكيك الإطارات الكبيرة بسرعة إلى أجزاء العلوي والجوانب والقضبان باستخدام شفرات قوية وقابلة للتعديل.

- يفصل جهاز فصل الخرز بفعالية وبشكل كامل الخرز المدمج في الإطار.

- ثم يتم تغذية كتل الإطارات التي تمت إزالة الخرز منها إلى جهاز تمزيق الإطارات للتكسير الموحد.

- يتيح نظام طحن وتصنيف الإطارات طحنًا ناعمًا وإزالة فعالة لكتل المطاط.

- فاصل الألياف يفصل الألياف.

ماكينات إعادة تدوير إطارات التعدين المهنية للبيع

مع استمرار تطور التعدين والهندسة والنقل وغيرها من الصناعات الثقيلة، يتزايد استخدام إطارات OTR. إن حجمها الكبير وخصائصها غير القابلة للتحلل تطرح تحديات مهمة في مجال البيئة وإدارة الموارد. في الوقت نفسه، يخلق سوق إعادة تدوير إطارات OTR فرص عمل غير مسبوقة حيث تعزز الدول دعم السياسات لإعادة تدوير الإطارات المستعملة.

تلتزم شولي بتوفير حلول إعادة تدوير إطارات OTR الفعالة والصديقة للبيئة لعملائنا في جميع أنحاء العالم. نحن نقدم تكوينات معدات مخصصة ونغطي العملية بأكملها، من تخطيط الموقع والتركيب من الباب إلى الباب إلى التدريب الفني وضمان مجاني لمدة عام. يساعد ذلك عملائنا على بدء الإنتاج بسرعة وتحقيق أرباح ثابتة. تم تصدير معداتنا إلى كندا وأستراليا وكينيا ودول أخرى وقد تلقت إشادة واسعة النطاق.

لا تتردد في الاتصال بنا اليوم للحصول على عرض أسعار إذا كنت ترغب في أن تكون الرائد في سوق إعادة تدوير إطارات OTR. شولي - شريكك الموثوق في معدات إعادة التدوير!